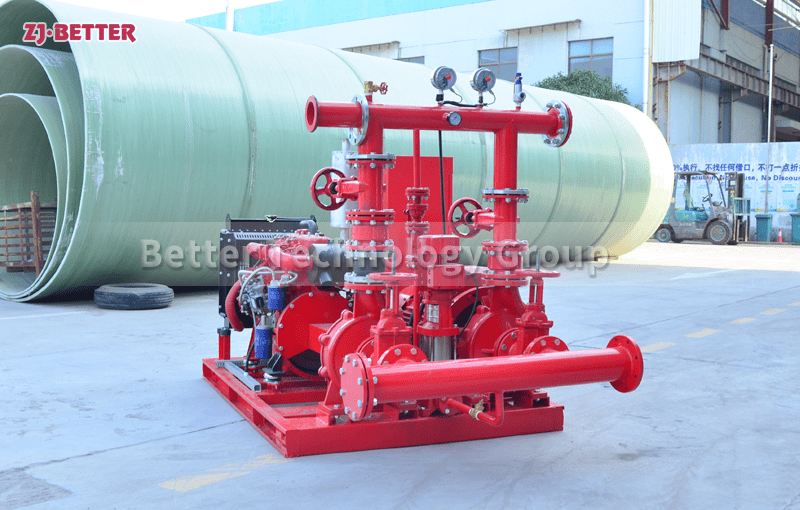

Standard Outdoor Fire Pump Set Equipment

Fire pumps are part of the applied water supply and are powered by electricity, diesel. They activate when the pressure in the fire sprinkler system drops below a certain level and provide a flow of water to the sprinkler system at very high pressure, which is then discharged onto the fire.

The Fire Pump Unit Controller is the brain of the pump set, designed to control and monitor the operation of the main, backup and jockey pump drives, and to compose pumps for manual and automatic modes, as well as to turn the pump drives on/off under specific conditions.

The fire pump pack controller detects signals through a set of built-in switches that reflect system pressure and flow status, enabling fire pump pack drives (electric/diesel/Jockey) to operate with system pressure below the set point, and due to power failure and/or a significant drop in pressure.