In today’s fire protection systems, the demand for rapid response, equipment reliability, and deployment efficiency is higher than ever. Especially in high-risk industrial zones, commercial buildings, and remote project locations, conventional split-type pump systems often fall short of meeting increasingly stringent fire safety requirements. To address these challenges, our company has developed an advanced Diesel Engine Integrated Fire Pump Unit, delivering a smartly engineered and highly efficient emergency response solution through structural integration, performance optimization, and intelligent control.

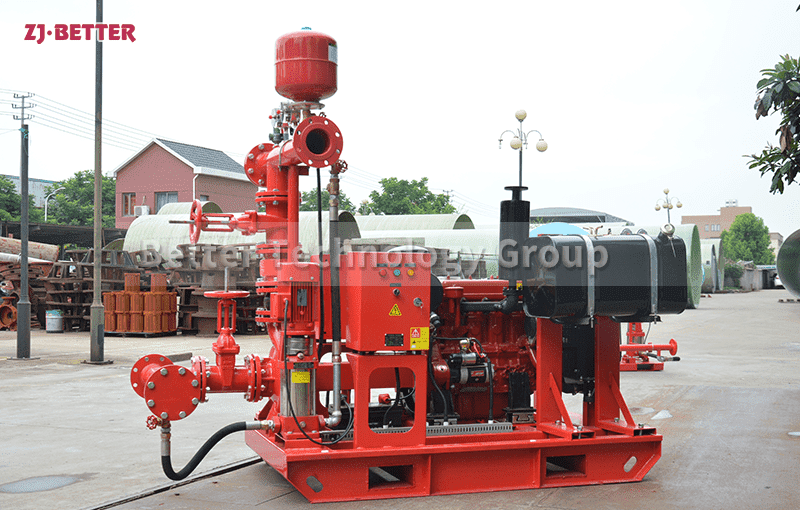

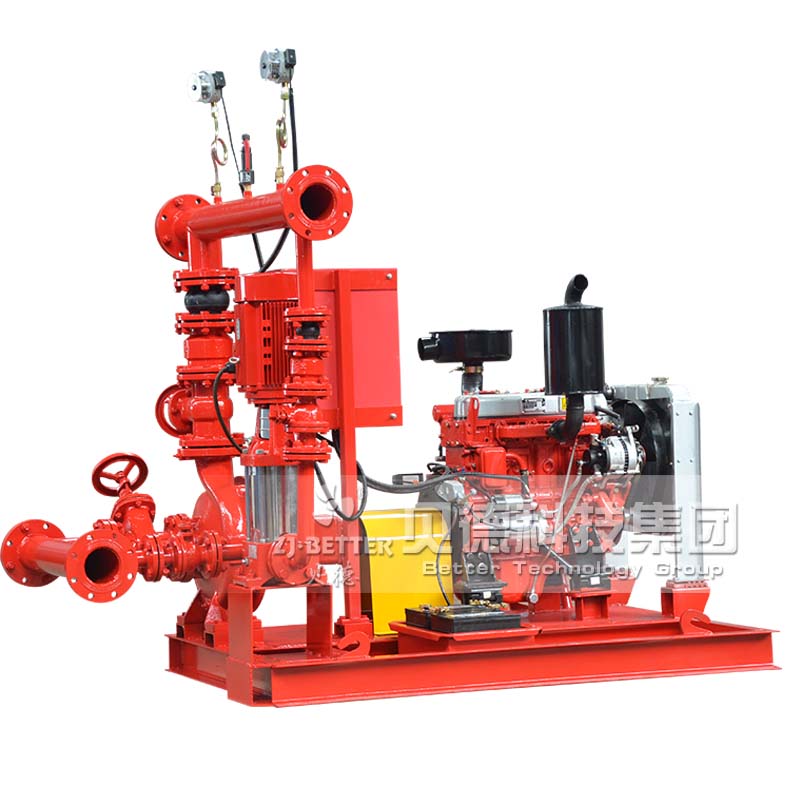

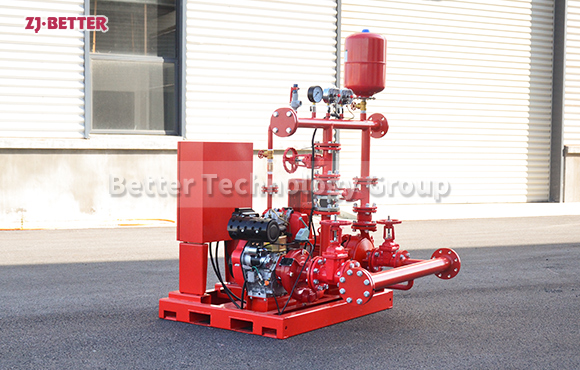

This all-in-one unit combines a diesel engine, fire pump, automatic control system, pressure maintenance components, stabilizing device, and alarm module into a single compact platform. The modular design ensures a minimal footprint and allows for flexible installation, even in space-constrained environments. Each unit is fully assembled and factory-tested prior to delivery, enabling rapid onsite commissioning. Users can simply connect the piping and power supply, achieving “plug-and-play” functionality that significantly reduces installation and labor costs.

Powering the unit is a high-torque industrial-grade diesel engine that ensures continuous and stable operation even in conditions where utility power is unavailable, during severe weather, or under emergency fire scenarios. The system maintains excellent thermal stability and mechanical durability even under frequent start-stop cycles or prolonged high-load operation. It can be paired with either a dual-suction or multistage centrifugal pump head, delivering high head and large flow rates, making it suitable for applications in high-rise buildings, tunnels, chemical plants, warehouses, and other challenging environments.

The integrated control system features a smart PLC panel with versatile operating modes, including automatic start, remote control, and emergency switchover. A user-friendly HMI interface enables operators to monitor real-time operating parameters, water pressure status, and alarm logs. The system supports multiple startup logics to accommodate specific site requirements, significantly enhancing system reliability and intelligent management capabilities.

From a safety perspective, this equipment is designed and manufactured in strict accordance with standards such as GB6245 and NFPA20, and is available with CCCF certification to ensure regulatory compliance and product reliability. The pressure maintenance system keeps the network stable during standby, preventing false alarms or unnecessary startups. When the system pressure drops to a critical threshold, the main pump can automatically activate within 5 seconds, ensuring a rapid firefighting response.

Additionally, the structure is treated with anti-corrosion coatings to suit both indoor and outdoor environments. Optional upgrades include soundproof enclosures, thermal insulation, and vibration-dampening bases to meet diverse operational needs for noise control, climate adaptability, and long-term maintenance.

In summary, the Diesel Engine Integrated Fire Pump Unit delivers powerful performance and stable water supply through a smartly consolidated system. Its intelligent control platform and plug-and-play readiness optimize emergency responsiveness, reduce operational costs, and simplify deployment. Representing a milestone in the development of integrated and intelligent fire protection technology, this unit is the ideal fire pump solution for industrial, civil, and infrastructure projects demanding high-level safety assurance.