Reliable Under Heavy Duty – Performance Analysis of Horizontal Split Case Fire Pumps

Horizontal split case fire pumps deliver high efficiency and stable performance under heavy-duty conditions. Ideal for industrial, energy, and high-rise building fire protection systems with large flow and high head demands.

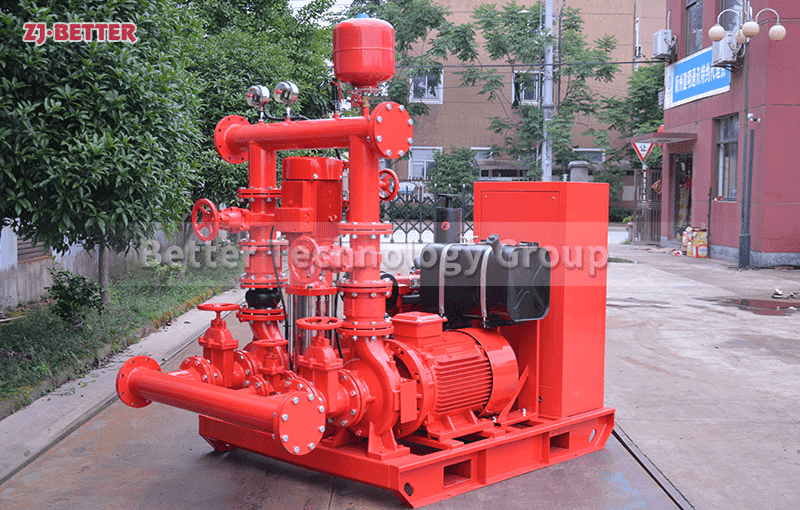

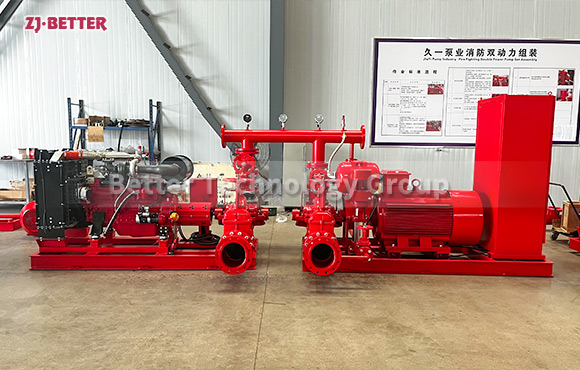

In the field of industrial fire protection, horizontal split case fire pumps stand out as the ideal choice for heavy-duty applications due to their superior hydraulic performance and robust structural design. These pumps offer a powerful combination of compact configuration, stable operation, large flow capacity, and high efficiency—making them suitable for scenarios requiring high head and large water volume. Whether in high-rise urban buildings, chemical plants, energy facilities, or large public infrastructures, this pump consistently delivers reliable water supply to meet emergency fire demands.

The dual-suction symmetrical design ensures balanced axial forces during operation, significantly extending the service life of bearings and mechanical seals while reducing noise and vibration. With suction and discharge flanges aligned on the same horizontal line, pipeline layout and installation are simplified, ultimately lowering system construction costs. The pump casing is made from high-strength cast iron or ductile iron, offering excellent corrosion resistance and structural integrity under complex working conditions.

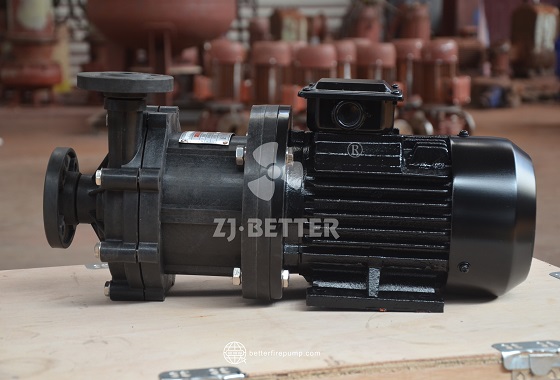

Hydraulically optimized dual-suction impellers allow the pump to maintain high efficiency under demanding conditions by minimizing hydraulic losses and maximizing energy conversion. Paired with a high-efficiency motor, the pump achieves powerful output while ensuring energy savings—translating into long-term operational cost reduction for users.

Each pump undergoes rigorous factory testing and dynamic balancing to guarantee stable performance in real-world applications. The pump’s user-friendly design makes maintenance straightforward and disassembly easy, ensuring minimal disruption during servicing and enhancing on-site system reliability and responsiveness.

In conclusion, the ZJ-BETTER horizontal split case fire pump embodies advanced fluid engineering and provides long-term, dependable support for high-load operations, making it an essential component in large-scale firefighting systems.