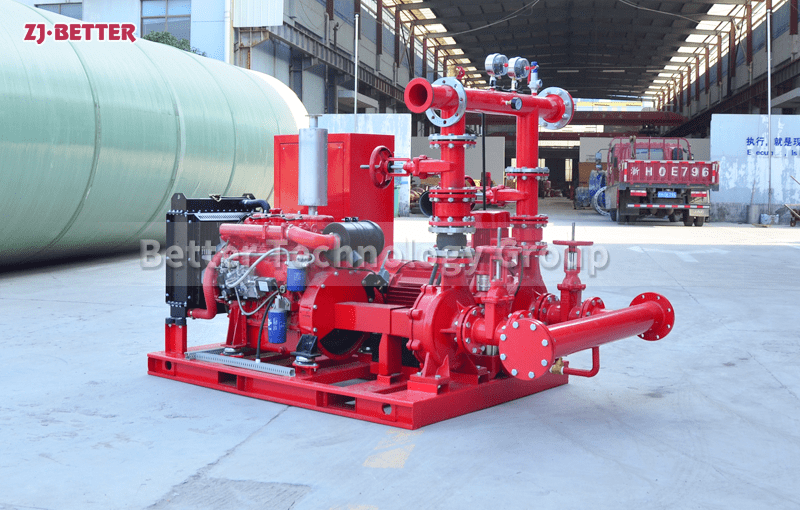

Durable Diesel Fire Pump for Harsh Environments: The Ideal Choice for High-Pressure and High-Head Applications

High-durability diesel fire pump engineered for harsh environments, delivering stable high pressure and high head performance. Ideal for industrial, remote, and high-risk fire protection systems.

Durable diesel fire pumps designed for harsh environments are professional-grade firefighting equipment specifically designed to handle high pressure, high head, and complex operating conditions. With their powerful output, superior structural strength, and adaptability to extreme environments, they are widely used in industrial fire protection, outdoor emergency water supply, energy and chemical projects, dock facilities, long-distance water transmission projects, and fire safety systems in large commercial buildings. These diesel fire pump systems are characterized by independent power drive, allowing for stable operation without relying on the power grid. Therefore, they maintain a strong water supply capacity even in the event of power outages, line faults, or remote areas without mains power, ensuring a continuous, reliable, and high-pressure stable fire water source during a fire. In practical applications, harsh environments often mean high temperature, high humidity, high dust, corrosive gases, frequent vibration, or continuous outdoor exposure in all weather conditions. The equipment must possess sufficient mechanical strength and environmental adaptability to ensure stable performance over many years of operation. Durable diesel fire pumps have been comprehensively reinforced to address these challenges. From the power system, pump body structure, shaft seal design, cooling mechanism, control system to the overall installation structure, highly reliable technical solutions are employed, enabling them to handle a variety of high-load tasks. The power unit uses a high-performance diesel engine, characterized by high torque, stable output, and strong load-bearing capacity. The high-pressure fuel injection system ensures complete combustion, improves power efficiency, and reduces fuel consumption, allowing the equipment to maintain stable output power during long-term continuous operation. Even in high-altitude, low-temperature, or high-temperature environments, the engine can still achieve reliable start-up and operation through an optimized intake system and fuel control strategy, which is particularly important for sites with less than ideal environmental conditions, such as remote areas, petrochemical plants, and large storage bases. The pump body is made of high-strength cast iron or ductile iron, and its corrosion resistance is enhanced by corrosion-resistant coating technology, enabling it to resist corrosion damage caused by sea winds, salt spray, moisture, and industrial gases. The internal hydraulic structure of the pump body has been optimized to provide high-efficiency, high-flow, and high-head output performance, meeting the needs of long-distance water delivery, large-area outdoor coverage, or high-pressure water supply for high-rise buildings. Its high lift capacity makes it stand out in water supply scenarios with elevation differences, maintaining stable pressure output whether for long-distance water supply in a factory or for sprinkler systems on the roof of a high-rise building. The shaft sealing system uses a mechanical seal structure, which effectively prevents leakage and extends equipment life, making it particularly suitable for scenarios requiring continuous long-term operation. Some models even use double-end mechanical seals or sealing structures with cooling systems, making them more suitable for high-temperature water, mildly corrosive media, or frequent start-stop conditions. To ensure stable operation under high temperature or high load conditions, the entire diesel fire pump system is designed with efficient cooling methods, including water cooling, air cooling, or a combination of cooling modes, which can be flexibly configured according to the installation environment. The radiator adopts a large-area, thick-walled structure, which can maintain strong heat dissipation capacity in hot weather or enclosed machine room environments, ensuring that the engine will not reduce power or shut down due to overheating, which is especially critical for continuous emergency water supply. In terms of operation and monitoring, the equipment is usually equipped with an intelligent control system that can monitor key parameters such as speed, oil pressure, oil quantity, water temperature, exhaust temperature, and operating status in real time, achieving safety protection and automated management. For example, the system can automatically alarm or shut down when it detects low oil pressure, high water temperature, or a malfunction to protect the equipment from damage. Furthermore, the control system supports one-button start, automatic monitoring start, or remote signal start/stop, and can be linked with fire control centers, fire control rooms, or building automatic fire suppression systems. When the fire alarm system issues a demand signal, the diesel fire pump can automatically start, rapidly reaching rated pressure output within seconds to ensure timely fire water supply. The equipment’s durability is reflected not only in the quality of its components but also in its overall structural design. The base uses a heavy-duty welded steel structure with excellent shock resistance, maintaining stability during transportation, relocation, or long-term operation. For ease of maintenance, common components such as oil filters, diesel filters, air filters, and cooling water pipes are designed for easy disassembly, making maintenance more efficient. The unit typically has a protective cover or semi-enclosed structure, ensuring heat dissipation while preventing dust, rainwater, or foreign objects from entering, making it suitable for long-term use outdoors or in dusty industrial environments. In project applications, durable diesel fire pumps are widely used in the petrochemical industry, oil refineries, power plants, ports, logistics parks, tunnel projects, water plants, municipal pipeline booster systems, and remote mountain fire water supply projects due to their advantages of high pressure, large flow rate, and independent power supply. For large-scale fire protection systems that need to operate in complex environments, it is not only a core water supply device but also a reliable safety guarantee for dealing with emergencies. Compared with ordinary fire pumps, these high-durability diesel fire pumps focus more on the ability to operate continuously for long periods under extreme conditions. They have longer engine life, stronger pump body wear resistance, more intelligent control systems, and more flexible installation methods, enabling them to maintain stable fire water supply performance at critical moments. In addition, they also have excellent energy utilization efficiency and high fuel economy, maximizing fuel consumption and reducing operating costs while ensuring high flow rate and high head output. This feature is very important for industrial users who value energy management and operating budgets. In summary, durable diesel fire pumps suitable for harsh environments, with their excellent power performance, robust structure, advanced control system, and strong environmental adaptability, are the ideal choice for high-pressure and high-head scenarios. Whether in extreme climates, remote areas, or demanding industrial environments, it can reliably provide a fire water source, ensuring the safety and continuity of the entire fire protection system. It is not merely a fire pump system, but a robust barrier protecting lives and assets in critical moments, providing sustained and powerful fire-fighting support for various high-risk scenarios.