High-Efficiency Applications and Technical Value of Compact Diesel Engine Fire Pumps in Independent Fire Protection Systems

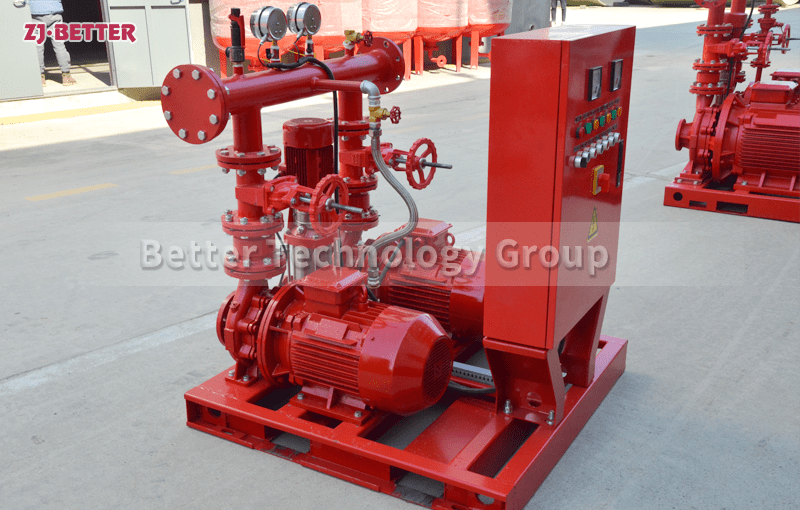

High-efficiency small diesel fire pump designed for independent fire protection systems, delivering reliable pressure, rapid start-up, and stable performance for diverse emergency scenarios.

With the increasing demands for reliability and mobility in modern engineering fire protection, small diesel engine fire pumps, with their compact structure, independent power supply, rapid start-up, and low maintenance, have become indispensable power units in independent fire extinguishing systems, demonstrating significant advantages, especially in remote areas, construction sites, temporary facilities, mobile fire brigades, and backup power configurations. Firstly, from an application perspective, small diesel engine fire pumps are suitable for environments without mains power or with unreliable mains power, such as outdoor temporary storage, mining areas, oilfield platforms, forest fire prevention, temporary loading and unloading areas at coastal docks, construction site rescue, and various emergency rescue scenarios. They typically serve as the primary or backup power source, combined with sprinkler systems, fire hydrant systems, and foam systems to provide immediate and continuous water support for firefighting operations. Due to their small size and portability, small diesel engine pumps are often designed as trailer-mounted, push-mounted, or chassis-fixed types, facilitating rapid deployment and on-site movement. They can be positioned and connected by a single person or a small group, greatly improving emergency response efficiency. At the technical level, the efficient application of small diesel engine fire pumps relies on several key design elements: First, the combustion and transmission efficiency of the power unit. Modern small diesel engines typically employ optimized combustion chambers, high-pressure fuel injection, and precise fuel supply control to provide stable torque at different engine speeds, thereby ensuring the pump maintains the required flow rate and head during high-load startup and continuous operation. Second, the hydraulic design of the pump body and impeller. Optimizing the impeller shape, volute flow channel, and flow-through materials for firefighting conditions can reduce cavitation risks while maintaining high efficiency, improving self-priming capability, and ensuring reliable pumping performance under complex water source conditions (including small amounts of impurities or low water levels). Third, the seismic design of the coupling and foundation structure. Small pump sets often need to operate in complex terrain or vibrating environments. High-strength couplings, flexible vibration damping devices, and reinforced bases help reduce vibration transmission, protect mechanical seals and bearings, and extend equipment life. Fourth, the reliability of the sealing and cooling system. Employing mechanical seals or composite seal structures, combined with appropriate cooling methods (air cooling or water cooling), ensures that the pump set will not experience performance degradation due to overheating or leakage during long-term high-intensity operation. Its technological value lies not only in the performance indicators of individual devices, but also in system integration and intelligent operation and maintenance. Modern small diesel engine fire pumps are often equipped with automatic control modules or linked with more advanced pump room control cabinets, enabling them to achieve automatic start-up, remote monitoring, fault diagnosis, and data recording. For example, when the fire pipeline pressure drops or a fire alarm is triggered, the control unit can automatically start the diesel engine after detecting the signal and complete steady-state water supply according to a preset program. Operating parameters (such as speed, oil pressure, water pressure, temperature, and fuel balance) are uploaded to the monitoring platform in real time, facilitating maintenance personnel to remotely assess the equipment’s health status and arrange preventative maintenance, thereby significantly reducing downtime risks and maintenance costs. Compared to electric pumps with equivalent functions, small diesel engine pumps have significant advantages in independence: they can still operate during power outages, have less dependence on external infrastructure, and are suitable for mobile deployment and temporary rescue; at the same time, they can achieve long-term continuous operation when fuel is sufficient, meeting the stringent requirements for continuous water supply in firefighting operations. In terms of energy efficiency, thanks to the optimized matching of the engine and pump body, small diesel engine fire pumps can maintain high fuel economy even under low and medium flow pressure conditions. Especially when used with a pressure stabilizing tank or pressure buffer device, it can reduce overall fuel consumption and mechanical wear by minimizing frequent start-stop cycles. Reliability and ease of maintenance are key reasons for its widespread adoption in independent fire suppression systems. Small pump units have a high degree of standardization, with clear maintenance cycles for common fault points (such as filters, spark plugs/injectors, belts, engine oil, and coolant). Replacement of vulnerable parts is quick, and unit maintenance mainly involves periodic inspections and replacement of consumables, reducing the frequency of professional maintenance intervention, making it suitable for scenarios with limited on-site maintenance conditions. Furthermore, due to its small size, spare parts and maintenance tools are easier to carry and store on-site. Safety design is also a crucial factor for small diesel engine fire pumps: high-quality fuel system design, anti-overflow fuel tanks, exhaust insulation or directional discharge to prevent fire spread, emergency stop switches, and multiple sensor protections (low oil pressure, overheating, overspeed, and start-up failure alarms) all enhance safety during on-site use. Furthermore, to adapt to diverse engineering needs, this type of pump offers a variety of configuration options: different diameter flanges, multiple outlet ports, variable or constant speed drive, different starting methods (electric start, manual start, pneumatic start), and additional devices (pressure stabilizer, silencer, thickened base, trailer mount, spare fuel tank), etc. Engineers can customize the selection according to project scenarios (such as high-rise pressurization, long-distance water delivery in the field, small warehouse fire fighting, or rapid rescue teams), thus balancing performance and cost. In terms of performance indicators, small diesel engine fire pumps can typically provide sufficient head and flow rate to drive sprinkler systems and multiple fire hydrants simultaneously under rated operating conditions. Their self-priming height, maximum suction head, and no-load start capability are given priority in the design to ensure that water pressure can be quickly established under varying water source conditions. Improved mechanical efficiency, pump efficiency, and overall transmission efficiency directly result in lower fuel consumption and lower operating temperature rise, thereby improving the continuous working capability of the equipment. In terms of implementation and inspection, small diesel engine pumps must undergo a series of quality and performance tests before leaving the factory, including no-load and load operation tests, leakage tests, vibration and noise tests, start-up reliability tests, and emission and fuel consumption measurements. Only after passing these tests can they be installed on-site. Furthermore, on-site installation should adhere to strict foundation and fixing specifications, ensuring that the coupling coaxiality, anchor bolt preload, and vibration damping system configuration meet requirements to avoid early failures due to improper installation. In practical engineering applications, a reasonable system design can maximize the efficiency of small diesel engine fire pumps. For example, when designing an independent fire extinguishing system, it is recommended to use a pump + pressure tank combination, allowing the pressure tank to compensate for short-term, low-flow leakage, and only activating the diesel pump when there is a larger flow demand, thereby reducing the diesel engine’s operating hours and extending its lifespan. Simultaneously, configuring automatic speed control or variable speed drive can adjust the pump speed according to instantaneous flow demand, further improving fuel efficiency and reducing mechanical shock. From an economic perspective, the procurement and operating costs of small diesel engine fire pumps are more advantageous compared to large units or complex fixed pump stations. Especially in scenarios requiring decentralized deployment or mobile use, the low procurement cost per pump, convenient transportation, and rapid deployment significantly shorten emergency preparedness time and reduce overall project investment. Furthermore, the modular design of the equipment facilitates expansion and upgrades. Subsequent additions of pressure stabilizing devices, linkage control, or remote monitoring modules have minimal impact on existing units, resulting in a good return on investment. Regarding environmental protection and regulations, the new generation of small diesel engines, through improved fuel injection and combustion control technologies, as well as matching exhaust gas treatment devices, can achieve lower emissions and better comply with regional environmental regulations. When selecting a model, priority should be given to power units that meet emission standards to ensure unrestricted deployment in cities or areas with emission restrictions. In summary, the efficient application of small diesel engine fire pumps in independent fire suppression systems is not only reflected in their independent power supply capabilities under complex environments and power outage conditions, but also in the high fuel economy resulting from optimized design, reliable start-up and long-term continuous operation capabilities, ease of maintenance, system integration and intelligent operation and maintenance potential, and positive contribution to the economic efficiency of the project. With proper system integration and scientific installation and commissioning, small diesel engine fire pumps can become flexible, efficient, and economical core power units in independent fire extinguishing systems, providing robust and reliable fire protection for various industrial, civil, and emergency scenarios, and significantly improving emergency response speed and fire extinguishing success rate in the event of a sudden fire.