Multistage electric fire pumps have a wide range of applications

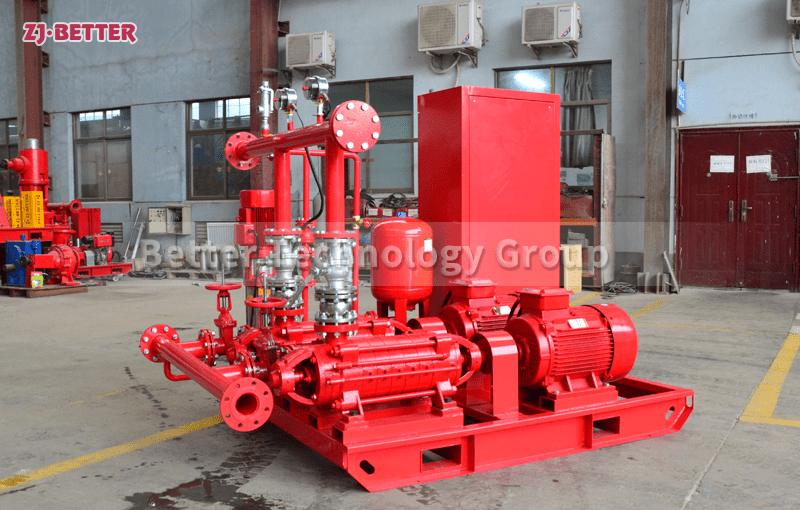

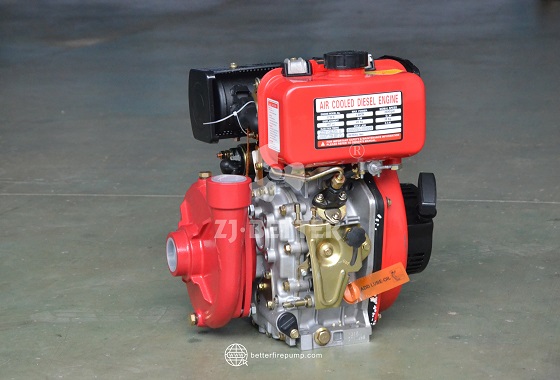

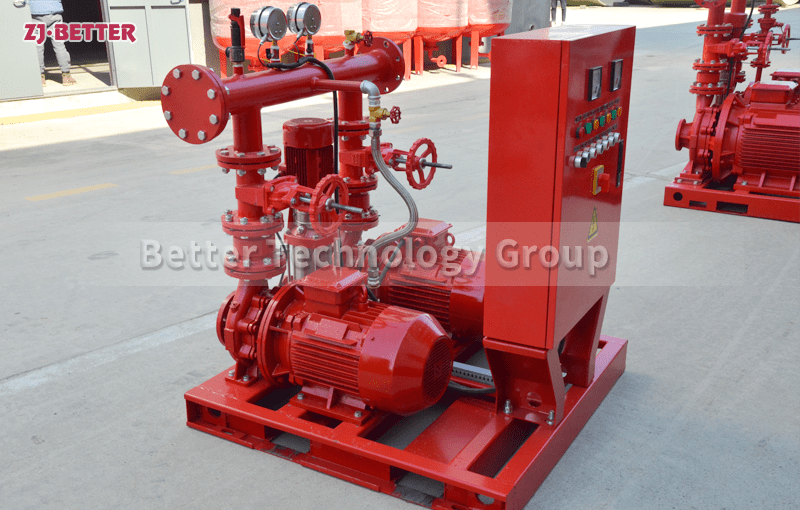

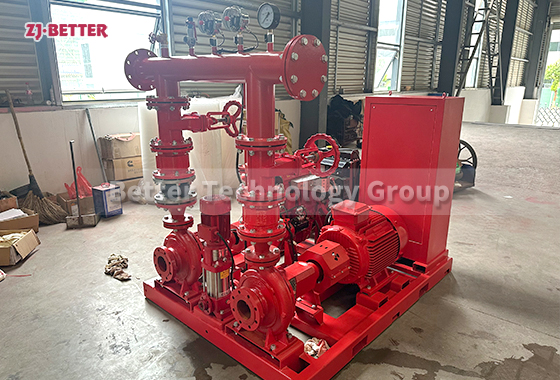

There are many types of multi-stage fire pumps, especially multi-stage fire pumps are more popular. Multi-stage fire pumps are a multi-functional product that can transport tap water and different liquids of various media, and can also be used in different Within the temperature range, different flow rates and different pressures can use multi-stage fire pumps. The application range of multi-stage fire pumps is very wide. It can be used in many industries such as petrochemical industry, medicine and food.

In production and life, fire pumps have the characteristics of a wide range of applications, such as in water treatment, fire safety and other departments. Fire pumps can not only be used in fire protection systems, multi-stage fire pumps can also be used in industrial production and urban construction, including industrial and urban water supply and drainage, and pumping water for high-rise buildings. Engineering fire pumps are used for fire pumps in engineering sites such as fire hydrant systems, water sprinkler fire extinguishing systems, and foam fire extinguishing systems.