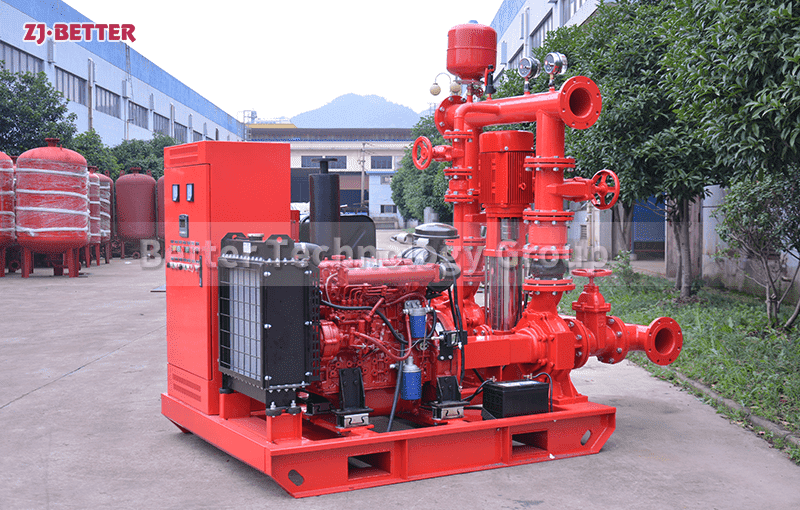

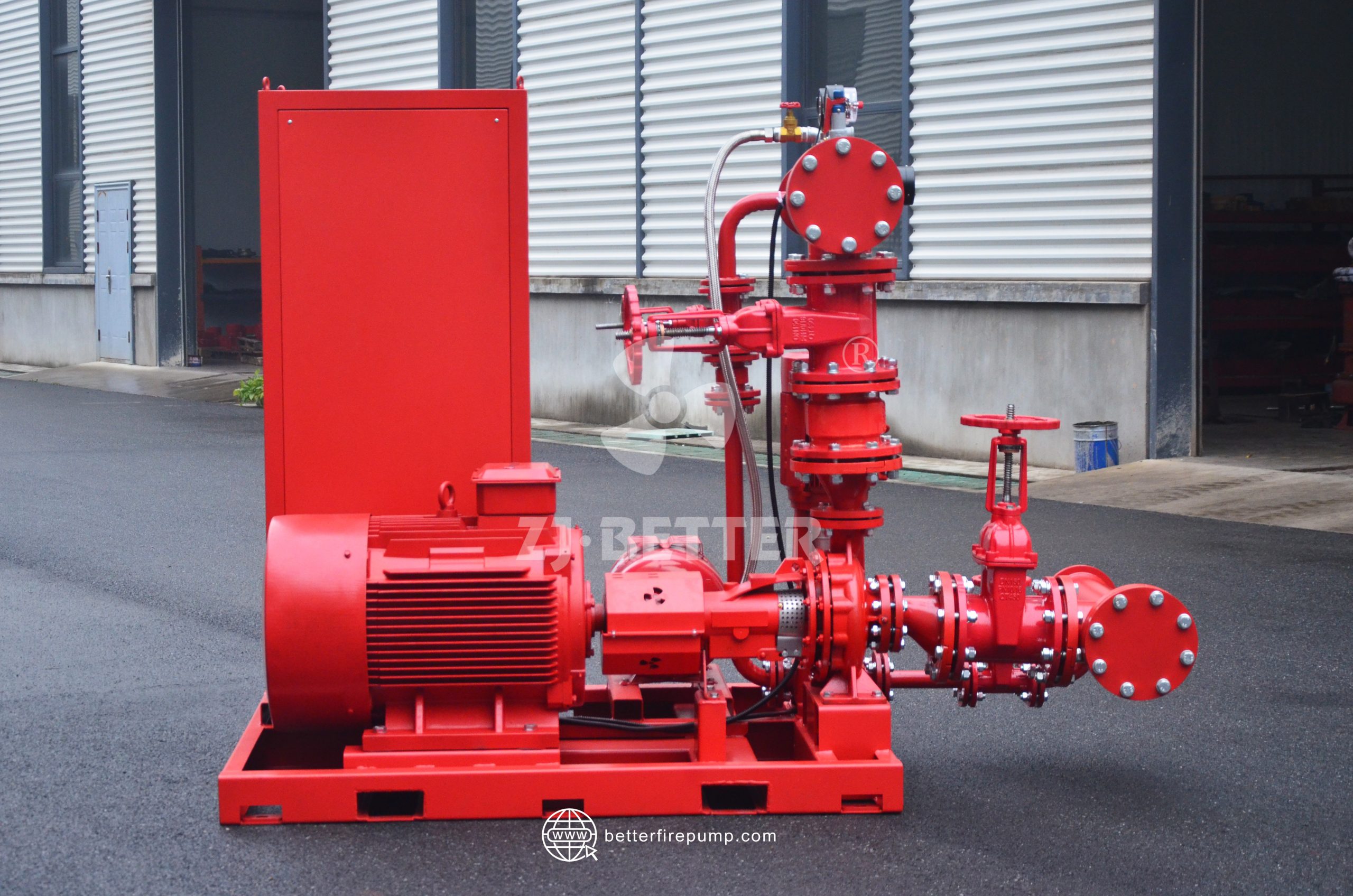

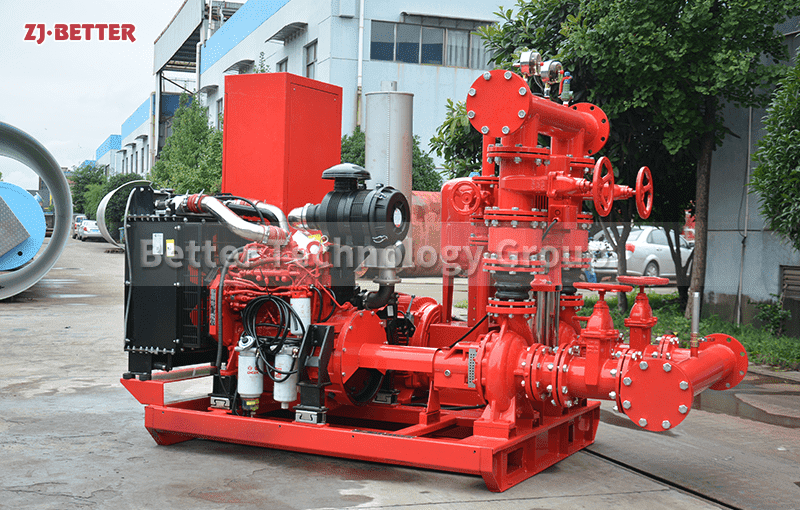

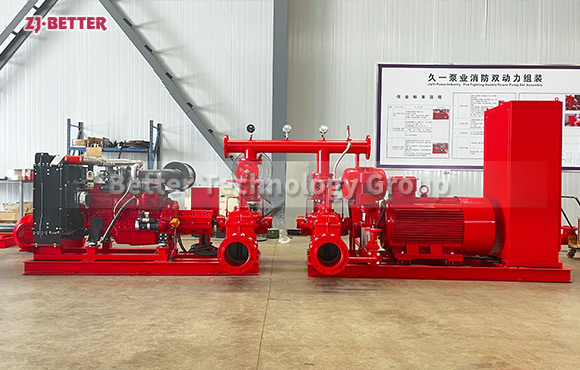

Versatile and Deployable: Open-Frame Diesel Fire Pump Set for Various Fire Scenarios

Discover the critical role of diesel fire pumps in power outage scenarios. Engineered for self-start and self-powering, these pumps offer high reliability, fast response, and autonomous operation—making them ideal for emergency and remote fire protection.

In various emergency rescue and firefighting applications, power outages are one of the most common and dangerous variables, especially in remote areas, during natural disasters, or at critical moments when urban infrastructure experiences sudden power failures. In such situations, diesel fire pumps capable of autonomous startup and self-powered operation become particularly critical. As a device that operates completely independently of the power grid, the diesel fire pump integrates a power system, control system, pump body, and alarm system into a single unit, enabling it to respond swiftly without external power supply and ensure continuous firefighting capability at critical locations. This product is the core equipment for ensuring safety in power-outage environments. Diesel fire pumps utilize high-performance industrial-grade diesel engines as their power source, offering exceptional starting reliability and durability. Upon receiving a start signal, the system can instantly ignite the diesel engine using a battery, even if the external grid is down, and drive the pump unit to operate efficiently. The entire system is professionally calibrated to ensure optimal balance between fuel efficiency and power output, thereby enhancing overall operational efficiency and extending the equipment’s service life. Especially in high-risk or remote areas such as chemical plants, warehouses, logistics facilities, ports, and outdoor construction sites, diesel fire pumps can serve as primary firefighting equipment, ensuring water supply for fire suppression at the first sign of a fire. In terms of modular design, these products typically feature an integrated base design, with all core components concentrated on a single base platform, facilitating transportation and lifting while simplifying the installation process. The compact structure and clear piping allow the control system to be integrated and managed through a centralized control panel, enabling manual startup or automatic startup logic settings, and integration with fire alarm systems. This design eliminates the need for complex wiring on-site, requiring only the connection of inlet/outlet pipes and batteries to complete commissioning and put the system into operation. For long-term maintenance needs, diesel fire pumps are generally equipped with multiple safety mechanisms such as a dual battery starting system, voltage display, oil level sensor, oil pressure protection, temperature protection, and overload shutdown. They also support optional remote monitoring, enabling users to monitor operational status and perform timely maintenance. Diesel fire pumps also exhibit exceptional environmental adaptability, particularly suited for locations without access to municipal power or with unstable power supply. They demonstrate strong adaptability in high-temperature, low-temperature, high-humidity, and high-dust environments. Additionally, customizable rainproof, dustproof, or explosion-proof enclosures can be provided to further expand application scenarios. From a performance perspective, the key advantage of diesel fire pumps lies in their independent power supply capability and rapid response mechanism, enabling them to start operations without relying on the city grid or power generation systems, truly achieving “availability when it matters most.” The pump body uses high-head, high-efficiency centrifugal pumps to ensure stable flow and pressure output even in complex piping systems. The engine components are typically equipped with renowned domestic and international brands such as Cummins, Yuchai, and Shangchai, offering robust power, ample spare parts availability, and a comprehensive service network. The control system employs a digital micro-control platform with multiple status displays, historical records, and alarm notifications, enabling fully automatic unmanned operation. In fire protection design, diesel fire pumps are often combined with electric pumps and pressure-stabilizing pumps to form diesel engine fire pump sets, achieving a multi-tiered fire protection system with routine pressure stabilization, fault switching, and emergency response capabilities, significantly enhancing system reliability and adaptability. In countries or projects with stringent fire safety regulations, diesel fire pumps are often mandated as mandatory components in initial building designs. Currently, with the development trends of intelligent fire protection and digital management, diesel fire pumps are also continuously evolving toward intelligence, integrating functions such as remote data collection, cloud platform operation and maintenance, and fault self-diagnosis to enhance user experience and reduce maintenance costs. Overall, self-starting, self-powered diesel fire pumps are not merely emergency equipment but also indispensable strategic equipment in modern high-reliability fire protection systems. Their emergence has filled the gap left by traditional electric pumps, which cannot operate in power outage scenarios, providing the final line of defense for high-risk and high-value locations. Whether in energy bases, oil and gas platforms, tunnel projects, highway service stations, or remote townships, diesel fire pumps have become a vital force in safeguarding life and property safety, thanks to their robust autonomous operation capabilities and sustained stable performance.