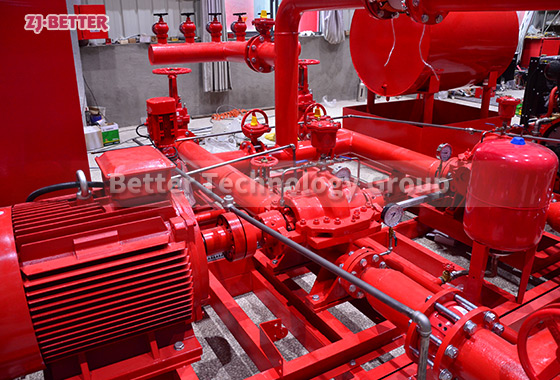

EEDJ fire pump set is a high quality fire pump made by Better

Fire pumps are part of the water supply to a fire sprinkler system and are powered by electricity, diesel or steam. The pump inlet is either connected to a public groundwater supply or to a static water source (e.g. tank, reservoir, lake). This pump provides higher pressure water flow to sprinkler system risers and hose risers. Our company can manufacture fire pumps that meet NFPA20 standards.

Fire pumps can function with electric motors or diesel engines. If local building codes require electricity independent of the local grid, pumps using electric motors can use the installation of an emergency generator when connected through a transfer switch listed.

Water pump: single-stage end-suction centrifugal fire pump, multi-stage fire pump, single-stage double-suction fire pump, submerged fire pump, rotor fire pump, in line with GB6245-2006 “Fire Pump Testing Requirements and Testing Methods” and NFPA20 (National Fire Protection Association ).