Upgrade Your Fire Protection: Fully Automatic Electric Pump Units for Modern Buildings

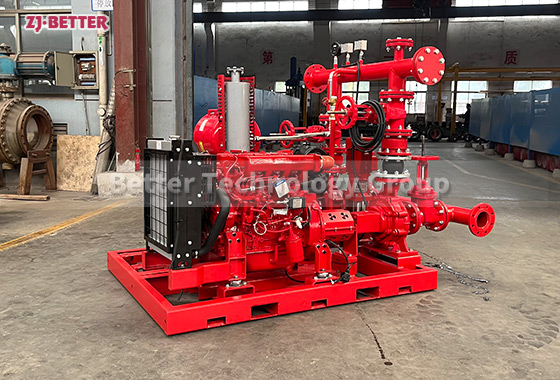

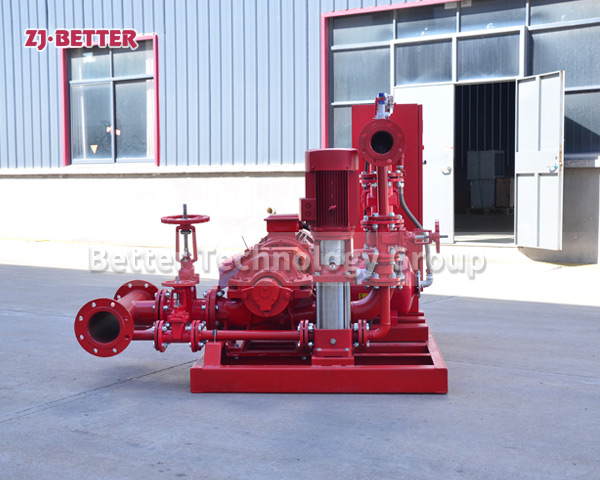

The fully automatic electric pump set offers an integrated and efficient fire water supply solution, ideal for modern buildings, high-rises, and industrial facilities. It features smart control, stable pressure, and energy-saving performance for enhanced fire protection.

Modern buildings have increasing requirements for fire protection systems, which not only require rapid response and high reliability, but also pay more attention to the intelligence level, operation efficiency and energy management of equipment. In this context, the fully automatic electric pump group, as an efficient, intelligent and stable fire water supply equipment, has become the preferred solution for upgrading the fire protection system of modern buildings, industrial plants, large supermarkets and underground buildings. The fully automatic electric pump group is a modular device that integrates multiple core components such as motor drive, control system, main pump, pipeline, pressure vessel and pressure switch. It has significant advantages such as compact structure, convenient installation, stable operation and simple maintenance. The equipment design fully considers the dual requirements of modern buildings for energy saving and continuous water supply capacity of fire protection equipment. Its high-performance motor drive system can achieve rapid start-up, ensure the first response when a fire occurs, and reduce the risk of delays in initial fire fighting; at the same time, the system’s built-in intelligent control panel cooperates with the pressure sensing module and automatic start-stop logic, which can automatically judge the water use status and control the start or shutdown according to the system pressure, truly realizing unattended and automatic operation. In addition, the pump group is usually equipped with one or more auxiliary pumps (such as pressure-stabilizing pumps, test pumps, etc.), which play a key role in daily low-flow use or system self-test, further improving the economy and safety of the overall operation. In practical applications, the fully automatic electric pump group shows extremely high adaptability. Whether in the pressure-stabilizing water supply system of high-rise buildings or in the complex water distribution system of large underground garages and industrial plants, the equipment can flexibly adjust the starting mechanism according to the actual pressure demand and water use status to ensure that the system water pressure is continuously stable, and greatly reduce the frequent start and stop of equipment and energy waste caused by pressure fluctuations. Its modular structural design makes on-site installation and commissioning more efficient and convenient for transportation, suitable for renovation projects and new construction projects. The control system is one of the core advantages of the equipment. It adopts an intelligent programmable logic controller (PLC) or an integrated automatic control box, with manual/automatic switching mode, fault self-diagnosis, data recording, remote communication and other functions, which not only ensures the real-time controllability of the system operation, but also can be remotely monitored and data uploaded through the Internet of Things platform to realize the integration of intelligent building systems. The system can preset a variety of operating parameters and automatically switch and protect according to the alarm information. For example, if the pump is overloaded, phase-lost, short-circuited, or abnormally pressurized, the power supply can be immediately cut off and an audible and visual alarm can be sounded, effectively preventing equipment damage and the spread of the fire. At the electrical control level, the electric pump unit strictly complies with the relevant national and industry standards for fire-fighting equipment, and has multiple protection mechanisms such as overload protection, short-circuit protection, and grounding protection to ensure the long-term stable operation of the motor system. The motor used is an energy-efficient product that meets national energy efficiency standards. With the frequency conversion control logic, it can also be used to adjust the system output pressure and further improve operating efficiency, especially for projects with significant water fluctuations. In terms of material selection, the pump body and piping system are mostly made of ductile iron or stainless steel, which have good pressure and corrosion resistance and can operate for a long time in high humidity, high temperature, or corrosive gas environments; the sealing system adopts a mechanical seal structure to effectively avoid the risk of water leakage and extend the maintenance cycle. The operating noise control of the pump group has also been highly optimized. The low-noise design of the motor and the shock-absorbing structure of the base can maintain a low decibel even under full-load operation, which is conducive to application in places with high noise control requirements such as office buildings, hospitals, and residential buildings. From the user’s perspective, the fully automatic electric pump group does not require special personnel to guard it. It only needs to set parameters and perform regular maintenance after installation, which greatly reduces the pressure of property management and equipment maintenance. The equipment maintenance interface is friendly and equipped with multi-point data collection and analysis modules. Operation and maintenance personnel can easily grasp the system operation status, discover potential problems in time, and prevent failures. As a new type of integrated fire water supply equipment, this product is not only applicable to building specifications under Chinese national standards, but also meets international standards (such as NFPA 20, EN12845, etc.) according to project requirements, which is convenient for export and international engineering applications. Its good adaptability, standardized interface design and flexible customization capabilities make it highly competitive in the global market. Especially in projects with limited equipment installation space, tight engineering schedule or limited on-site construction conditions, the fully automatic electric pump group, with its “plug and play” advantage, provides great convenience and cost savings for the engineering party and the end customer. In addition, with the proposal of the “dual carbon” goal, the demand for energy-saving equipment in green buildings is increasing. Compared with traditional diesel pumps or split pump room systems, this type of electric pump group performs better in carbon emissions, energy consumption and system integration, becoming one of the important scoring items in the green building evaluation system, and also winning higher environmental protection and safety scores for the construction party. On the whole, the fully automatic electric pump group, with its integration, efficiency, intelligence and reliability, has shown irreplaceable engineering value in the modern building fire protection system, which not only improves the fire emergency response capability of the building, but also promotes the entire fire protection industry to develop in the direction of intelligence, modularization and greening. It is an ideal choice for upgrading and sustainable development of building fire protection systems. Whether it is the construction of a new large complex or the intelligent transformation of an old fire protection system, the fully automatic electric pump group provides a stable, efficient and easy-to-maintain solution. Its high adaptability and modular advantages also bring great convenience to design units and construction units, and become an indispensable part of modern fire protection engineering.