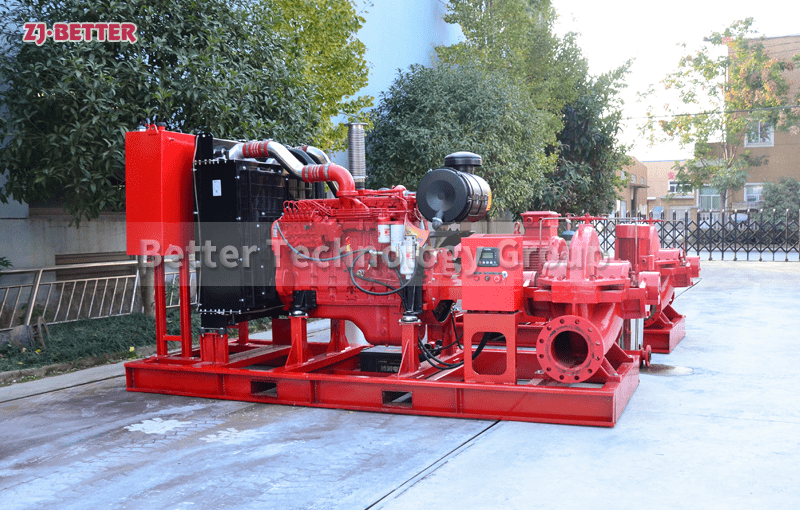

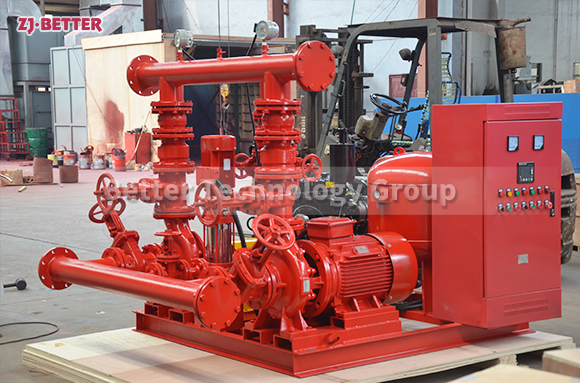

Vertical Long Shaft Fire Pump System Designed for Large Industrial and Tank Farm Applications

The vertical long-shaft fire pump is a high-performance fire-fighting device specifically designed for high-rise buildings, industrial areas, chemical plants, power plants, and docks. It features high flow rate, high head, stable operation, and long service life. Utilizing a long-shaft drive and multi-stage guide vane structure, it ensures efficient water supply and continuous pressure output, adapting to various working conditions and water source environments. Supporting electric motor or diesel drive, it can be automatically controlled and remotely monitored, making it an ideal choice for achieving highly efficient, energy-saving, safe, and reliable fire-fighting systems.

Vertical long-shaft fire pumps are high-performance fire-fighting equipment designed for locations requiring long-distance, high-flow, and high-lift water supply, such as large industrial areas, tank farms, docks, shipyards, power plant cooling systems, and high-rise buildings. Their design philosophy aims to achieve a perfect combination of powerful performance, continuous and stable water supply, and ultra-long service life. These fire pumps utilize a vertical structural layout, separating the motor from the pump body. The motor is located on the ground, while the pump body extends underwater or into a storage tank, ensuring efficient water extraction from deep wells, underground pools, or locations with low water levels, providing a continuous and stable high-pressure water flow to the fire-fighting system. The most significant structural feature of vertical long-shaft fire pumps lies in their long-shaft drive system. The shaft is composed of multiple connected sections, made of high-strength stainless steel or carbon steel, and precision-machined and dynamically balanced to ensure stable transmission and extremely low noise. This design not only reduces vibration and energy loss but also ensures extremely high mechanical efficiency during long-term operation. Its unique multi-stage guide vane structure design enables the pump to maintain excellent hydraulic performance in high-head applications. Each stage of guide vanes is optimized for fluid dynamics, effectively reducing flow resistance, improving efficiency, reducing wear, and extending equipment life. The motor drives the impeller to rotate via a vertical drive shaft. The streamlined design of the suction inlet at the bottom of the pump body ensures stable water intake even at low water levels, preventing cavitation and guaranteeing continuous water supply. In terms of performance, the vertical long-shaft fire pump can provide a flow range from 50 to 5000 cubic meters per hour, with a head exceeding 150 meters, fully meeting the complex fire protection needs of large industrial facilities, chemical storage tank areas, and power plant cooling towers. Its flexible starting method allows for configuration with electric motor drive, diesel engine drive, or a dual electric + diesel drive system, enabling normal operation under different power supply conditions, making it particularly suitable for areas with unstable or easily interrupted power. The reliability of this pump set is reflected in several aspects. Firstly, the pump body and bearings adopt a self-lubricating or water-lubricating structure, with a rationally designed bearing spacing to effectively support the drive shaft, reduce friction loss, and ensure smoother operation. Secondly, the sealing system employs mechanical seals or packing seals, providing excellent leak-proof performance. It can be customized according to the media properties and is suitable for clean water, seawater, or mildly corrosive liquids. The motor and control system are equipped with multiple safety functions, including overload protection, phase loss protection, and temperature rise alarms, ensuring stable operation even under extreme conditions. Vertical long-shaft fire pumps not only excel in performance but also demonstrate significant advantages in installation and maintenance. Due to their small footprint and mostly integral installation structure, installation simply requires vertically placing the pump body into a water tank or well and connecting the pipeline and power supply, greatly simplifying the construction process. This design is particularly practical for space-constrained or underground fire pump rooms. In terms of maintenance, since the motor and transmission components are located on the ground, maintenance can be performed without disassembling the entire pump body, only requiring operation on the ground portion, reducing labor and downtime costs. Regarding energy efficiency, vertical long-shaft fire pumps utilize a high-efficiency hydraulic design, achieving a pump efficiency of over 80%, saving 10% to 20% more energy than traditional horizontal centrifugal pumps. Meanwhile, its long-shaft drive system minimizes energy loss, and combined with precise impeller clearance control and optimized guide vane structure, makes overall operation more energy-efficient and effective. During long-term operation, the equipment maintains stable flow and head output, meeting high-standard fire water supply requirements. This equipment plays a crucial role in fire protection systems, serving not only as a main pump but also often working in conjunction with pressure-stabilizing pumps, sprinkler pumps, foam pumps, etc., to form a complete automated fire water supply system. Through integration with an intelligent control cabinet, the system can achieve automatic start/stop, remote monitoring, and data recording. Once the pipeline pressure drops or a fire signal is triggered, the pump unit will automatically start supplying water, ensuring sufficient water supply to the fire extinguishing system immediately. Simultaneously, the pump unit has an emergency manual start/stop function, allowing manual operation even in the event of a control system failure or power outage, ensuring fire safety is not affected. To adapt to different needs, the vertical long-shaft fire pump can be customized according to the operating environment and water source conditions. For example, impellers and pump bodies made of different materials, such as cast iron, stainless steel, and bronze, can be selected to adapt to fresh water, seawater, or mildly corrosive media. For environments with high-temperature or impurity-containing water sources, filtration devices and high-temperature resistant sealing structures can be added to ensure long-term stable operation of the pump. This customization capability allows it to be efficiently matched in various engineering projects, making it an ideal fire-fighting water supply equipment for oil depots, chemical plants, power plants, ports, and other fields. In terms of safety, all key components of the vertical long-shaft fire pump undergo rigorous quality testing, including dynamic balancing and performance testing before operation, ensuring excellent operational stability and reliability for each unit upon leaving the factory. Some models also support integration with fire remote monitoring systems, real-time monitoring of operating status, pressure, flow, and temperature, and automatic alarms for abnormal conditions, providing comprehensive safety assurance for large facilities. From a long-term perspective, the vertical long-shaft fire pump, with its high efficiency, low energy consumption, long lifespan, and reliable performance, has become one of the main equipment in the fire protection industry. It not only meets the current requirements of high-rise buildings, industrial facilities, and urban infrastructure for efficient and intelligent fire protection systems but also lays a solid foundation for the future development of energy-saving, environmentally friendly, and automated fire protection systems. Whether in emergency water supply, industrial cooling, or urban fire fighting, vertical long-shaft fire pumps have become an indispensable core equipment in safety assurance systems due to their excellent performance and reliability, providing efficient, safe, and long-lasting power support for fire protection projects worldwide.