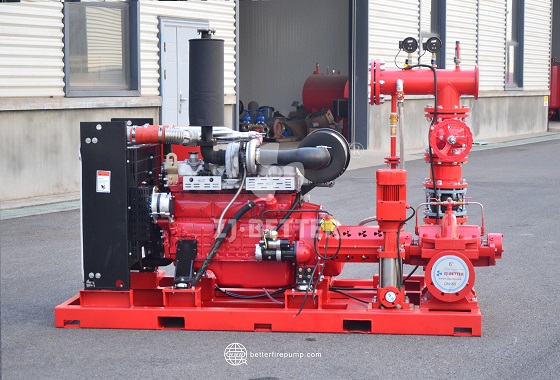

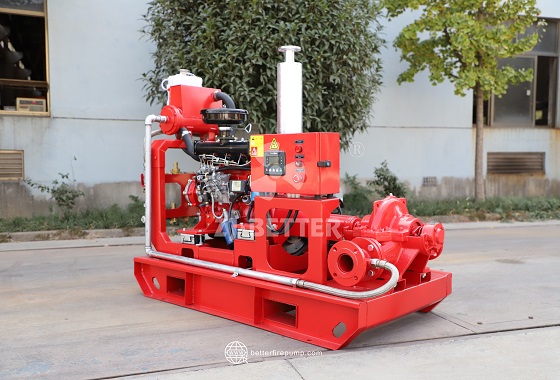

Independent Power Fire Pump Set: Efficient Fire Protection Solution for Off-Grid Environments

The diesel engine-driven independent power fire pump unit has the advantages of strong power, power outage availability, automatic control, high head and large flow. It is suitable for high-rise buildings, industrial parks, petrochemicals, power plants and remote areas, ensuring continuous and stable fire water supply and providing safe and efficient fire extinguishing solutions.

Diesel-powered, standalone fire pump units are specifically designed to ensure reliable firefighting systems under all circumstances. Their greatest advantage lies in their independent operation without relying on an external power supply, providing a more reliable firefighting solution for a wide range of locations. They are particularly ideal for areas with limited or frequent power outages. These units primarily consist of a high-performance diesel engine, a sturdy chassis, a high-quality pump body, an advanced control system, and a robust piping system. Each component has been meticulously designed and rigorously tested to ensure rapid start-up and long-term, stable water supply in emergencies. The diesel engine, as its power source, boasts high fuel efficiency and stable power output, capable of maintaining robust output in harsh environments. Compared to electric fire pump units, their greatest advantage is their reliability in areas without or even without power. Diesel fire pump units offer an optimal firefighting solution for remote factories, storage centers, mining areas, and offshore installations far from the urban power grid. The pump body is constructed of wear-resistant and corrosion-resistant materials, ensuring structural stability and undiminished performance even under prolonged, high-pressure operation. Suitable for transporting clean water or firefighting water with minimal contamination, it also boasts a long lifespan and low maintenance. In terms of control systems, these devices are typically equipped with an automatic control panel featuring automatic start/stop, fault alarm, and oil level monitoring. This ensures that in the event of a fire, the pump can be activated without human intervention, quickly establishing stable water pressure and avoiding delays in firefighting due to untimely operation. Automated control significantly enhances the system’s intelligence, enabling managers to more efficiently and safely ensure the continuity of firefighting water supply. In terms of performance, diesel engine-powered independent firefighting pumps typically offer high flow rates and high lifts, meeting the needs of high-rise buildings, large industrial plants, and long-distance water delivery. They offer a wide range of rated flow rates and pressures, allowing customization based on specific project requirements. Some models even support dual-power switching or can operate in parallel with an electric pump unit, creating a dual-failure water supply system. If one pump unit fails, the other can immediately take over, ensuring the continuity and stability of the firefighting system. Compared to electric pumps, diesel engine pumps are more adaptable to high temperatures, humidity, and power outages, maintaining optimal operation under these extreme conditions. Diesel engine fire pump sets are used in a wide range of applications, from high-rise residential areas in cities to industrial parks, from petrochemical bases to power plants, to warehouses and logistics, and underground facilities. Their application is particularly prominent in developing countries and regions with underdeveloped power infrastructure, where power outages are common and the consequences of fire protection systems failing at critical moments can be devastating. The independent operation capabilities of diesel engine pump sets make them a crucial last line of defense for fire safety in these scenarios. Beyond their use in fire water supply, they are also commonly used in emergency drainage and flood control. When widespread flooding occurs, diesel engine pumps can be quickly deployed, buying valuable time for drainage and rescue efforts. Their advantages lie not only in their performance and adaptability, but also in their ease of maintenance and use. Modern diesel fire pump sets are designed with the user’s maintenance needs in mind. They feature a compact structure, a small footprint, and a well-organized layout between the pump and engine, facilitating easy inspection and maintenance. Highly standardized components facilitate replacement and long-term use. The diesel engine itself boasts a long lifespan and extensive maintenance intervals. Combined with advanced lubrication and cooling systems, these units maintain long-term operation without overheating or wear, reducing operating costs. Safety is a key design consideration for this type of equipment. Diesel pump sets are typically equipped with comprehensive protective devices, such as low oil pressure alarms, over-temperature alarms, low oil level warnings, and automatic shutdown protection. These measures ensure that any abnormalities during operation are promptly shut down or alert maintenance personnel, preventing damage or further accidents. Furthermore, the units utilize shock-absorbing design and noise-reducing materials for smoother and quieter operation, enhancing the user experience. With technological advancements, more and more diesel fire pump sets are incorporating intelligent and remote monitoring technologies. Users can monitor pump operating data, including speed, water pressure, oil level, and temperature, in real time via remote terminals. Remote control and fault diagnosis capabilities make equipment management more efficient and intelligent. This functionality is particularly useful for large-scale industrial projects requiring centralized management of multiple pump sets, as it not only improves management efficiency but also reduces the cost and risk of manual inspections. From an environmental perspective, modern diesel fire pump sets are constantly being optimized, featuring low-emission and low-noise engines that meet international environmental standards. Improved fuel efficiency also reduces operating costs, further enhancing their economical and sustainable nature. In summary, diesel-powered, independent fire pump sets, with their independent power supply, strong performance, wide range of applications, convenient maintenance, and intelligent control systems, have become indispensable firefighting equipment in various locations. They not only provide a stable and reliable water supply for firefighting systems at critical moments, but also adapt to various complex and harsh environments, ensuring safety, stability, and efficiency. Whether it is a high-rise building, industrial zone, petrochemical project or remote mining area, this pump unit protects people’s lives and property safety with its excellent performance and reliability.

管道泵(不锈钢304316L).jpg)