Fire Protection Unaffected by Power Outages: A Comprehensive Overview of the Integrated Diesel Engine Pump System

The integrated diesel engine pump station offers autonomous power, high head and flow, and smart control—ideal for fire protection in power outage scenarios and high-security facilities.

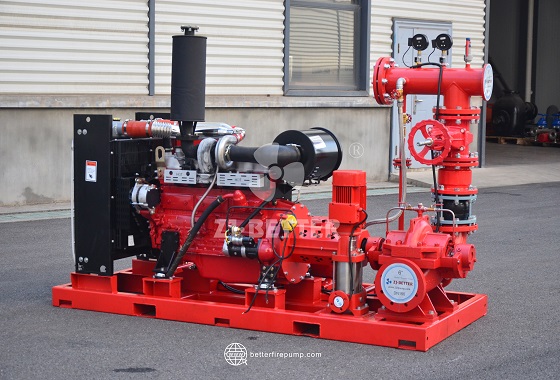

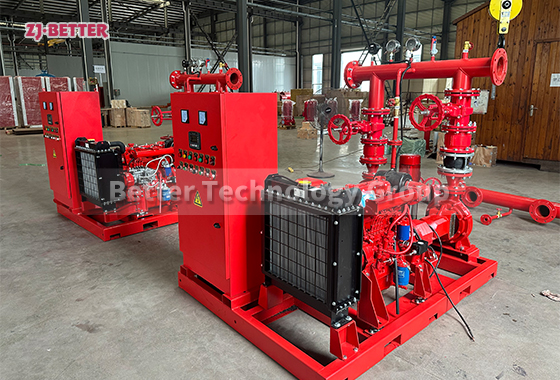

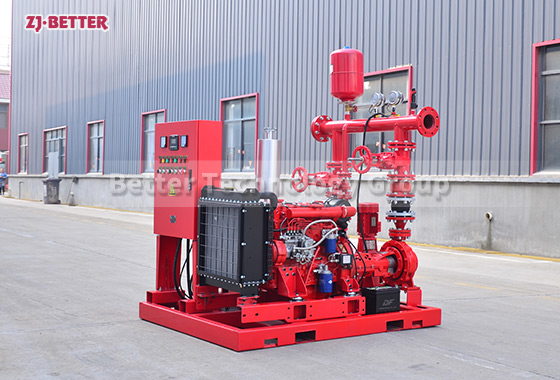

In modern fire protection engineering, the reliability of water supply equipment is paramount, especially in emergency scenarios. In critical environments such as industrial facilities, data centers, high-rise buildings, underground spaces, and logistics hubs, ensuring uninterrupted firewater supply during power outages is vital. The integrated diesel engine pump station system emerges as the optimal solution to this challenge. Powered by an independent engine-driven system, this all-in-one platform incorporates a high-efficiency pump unit, hydraulic components, control cabinet, fuel tank, and automatic start-stop functionality. It can autonomously activate in case of power failure, instantly delivering water pressure for firefighting operations and significantly improving emergency response effectiveness.

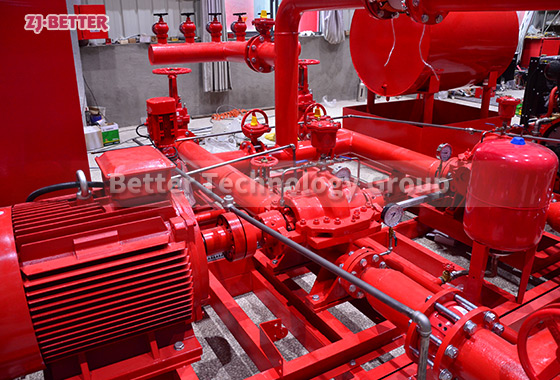

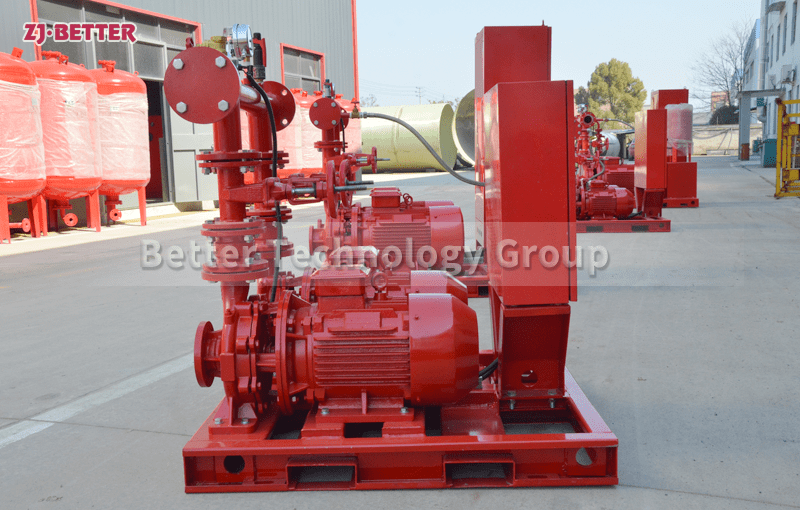

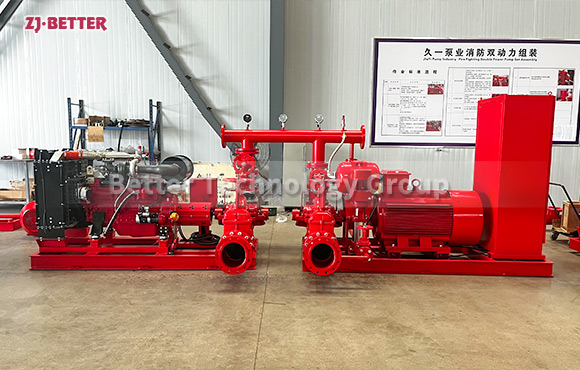

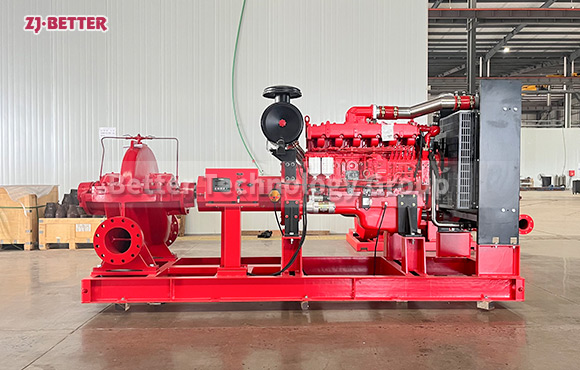

The system is driven by globally recognized diesel engines known for their performance under extreme conditions. Whether in sub-zero climates or hot, humid tropical zones, the diesel engine delivers consistent, stable power output. The pump unit typically features high-grade cast iron or ductile iron construction, offering exceptional wear resistance and durability. Through advanced hydraulic simulation and structural optimization, the pump achieves an ideal balance of high head, large flow rate, and low energy consumption—ideal for high-rise water supply, remote firefighting lines, and extensive sprinkler networks. The integrated control cabinet includes a smart microcontroller that enables automatic fault detection, autonomous start-up, seamless switching, and 24/7 real-time system monitoring. Optional communication modules support remote access for fire control centers or facility management platforms.

This pump station can also be equipped with a pressure stabilization pump, expansion tank, energy storage devices, auto-refill systems, and air release valves, forming a complete closed-loop fire protection solution. The entire system is mounted on a unified skid base with vibration isolation support to reduce noise and enhance operational stability and service life. For space-constrained projects, the pump station is fully customizable in dimensions, port orientation, flow/head parameters, and engine type to ensure optimal configuration and installation.

From a maintenance standpoint, the integrated diesel pump station simplifies routine servicing through centralized design and component layout. Diesel level monitoring and alerting systems prevent fuel shortages that could interrupt pump operations. Embedded fault logging and operation records provide data for diagnostics and preventive maintenance. All electronic and control components meet or exceed IP54 protection standards, making the system suitable for demanding environments like dusty, humid, or outdoor settings.

Application-wise, this diesel pump system is ideal for airports, subways, chemical plants, power stations, shipyards, tunnels, convention centers, oil depots, and ports—especially in zones with unreliable or no grid power. With complete off-grid capability, it complements or substitutes conventional electric firefighting pumps. Increasingly, modern construction projects integrate such systems into their initial design, ensuring redundancy and enhancing fire protection resilience.

Importantly, each unit undergoes strict factory testing and simulated emergency drills to verify compliance with international fire safety standards such as NFPA20, ISO. For export projects, complete technical documentation—including certifications, third-party test reports, and certificates of origin—are available to meet local regulatory demands. Global technical support and localized after-sales service ensure professional assistance throughout the project lifecycle.

In conclusion, the integrated diesel engine pump station system delivers unmatched performance, reliability, and maintainability. Through modular integration and smart design, it sets a new benchmark for modern fire pump systems. As fire protection demands grow more stringent, this solution is set to play an increasingly vital role in safeguarding key infrastructure across the globe.