High-Efficiency Dual-Motor Fire Pump System for Smart Firefighting Solutions

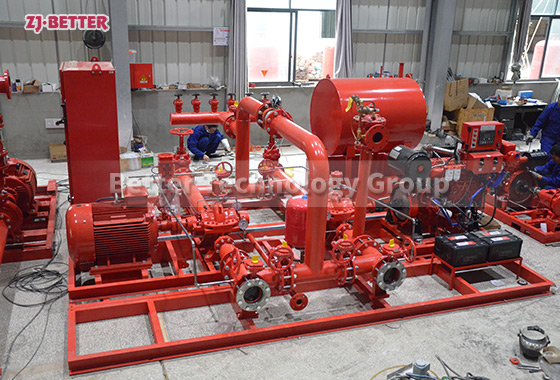

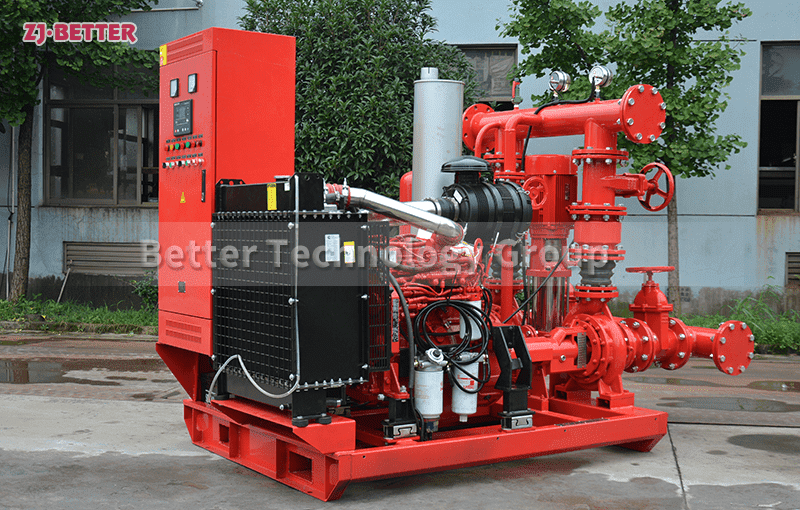

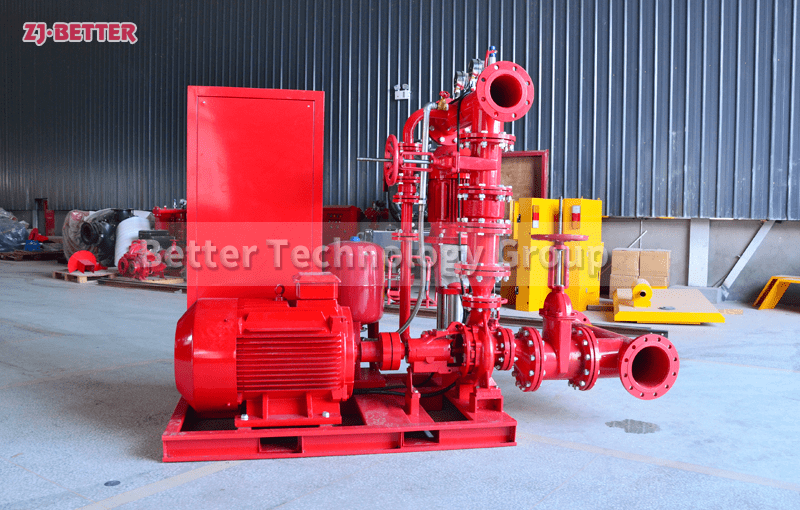

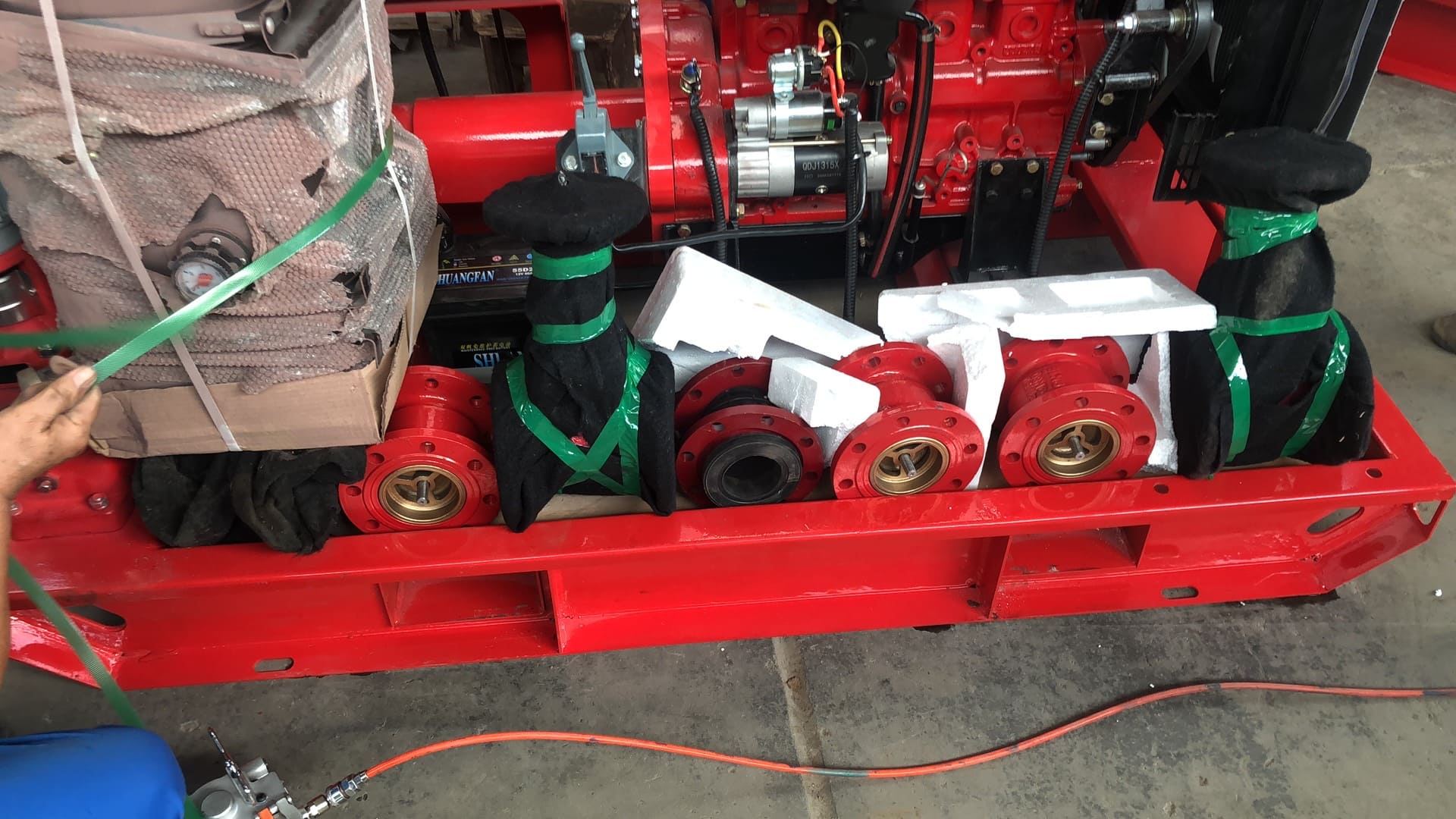

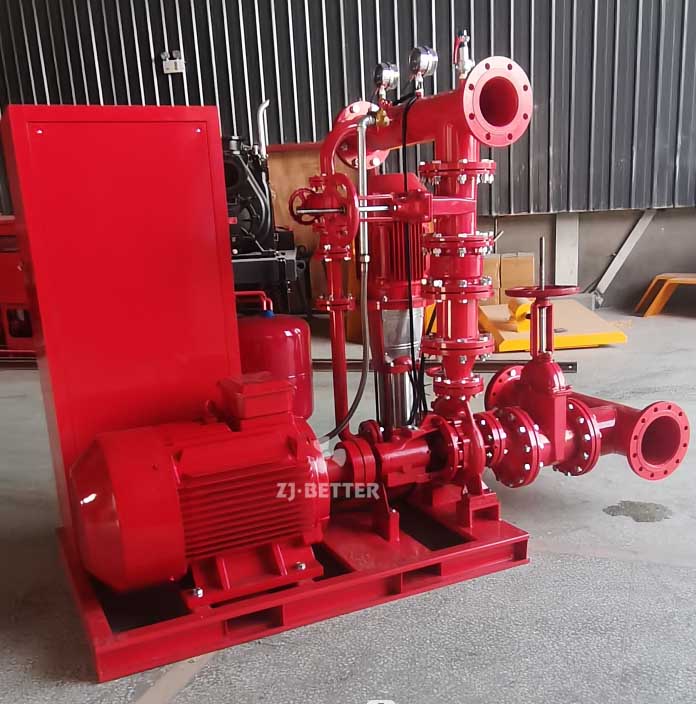

This high-efficiency dual-motor fire pump system is designed to meet the fire protection needs of modern buildings and industrial facilities. It integrates a main pump and a jockey pump to ensure rapid water supply during emergencies. Equipped with an intelligent control panel, the system supports automatic start/stop, remote monitoring, and fault alarms, significantly enhancing ease of operation and operational reliability. With its compact structure and small footprint, it is ideal for high-rise buildings, logistics parks, chemical plants, and more—making it a key component of intelligent fire protection systems.

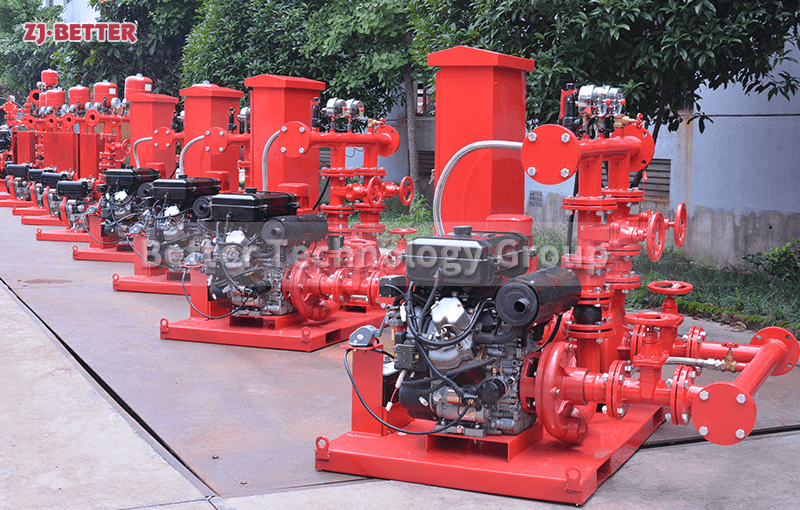

As a high-tech enterprise specializing in the development and manufacturing of fire pump systems, the company is committed to delivering safe, efficient, and intelligent fire water supply solutions. Its product range includes electric pump sets, diesel pump units, constant pressure systems, and integrated fire protection packages, serving a wide array of sectors such as municipal infrastructure, construction, industry, and energy. With automated production lines, comprehensive testing systems, and a skilled technical team, the company continuously enhances product performance to meet the demanding standards of both domestic and international markets.