Performance and Application Analysis of Vertical Multistage Fire Pump System

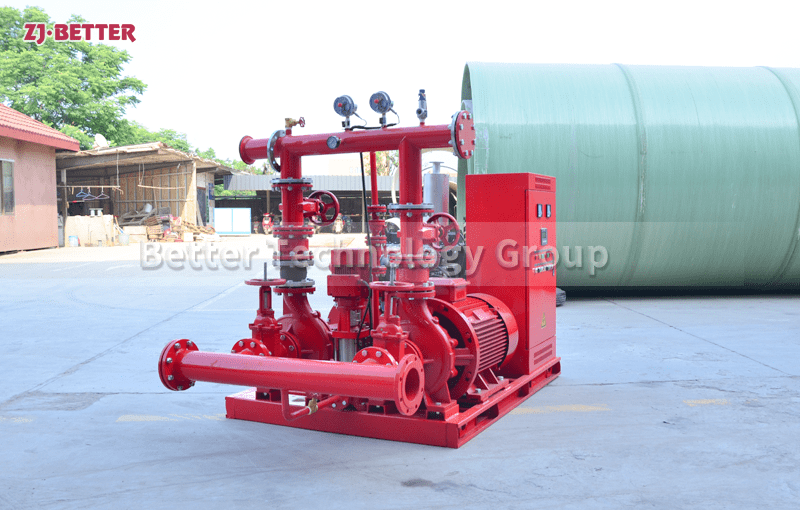

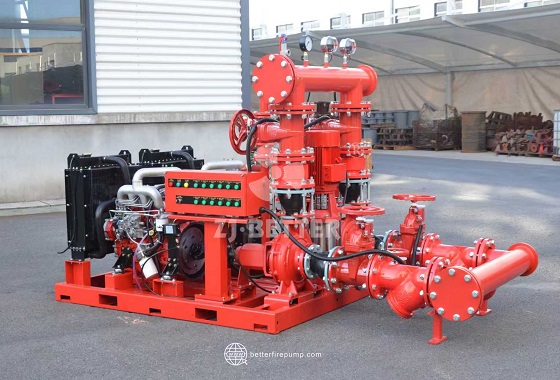

Vertical multi-stage pipeline fire pump sets are high-head, high-efficiency firefighting water supply equipment featuring compact structure, energy efficiency, quiet operation, and stable performance. Suitable for sprinkler systems, fire hydrants, and automatic fire suppression systems in high-rise buildings, industrial plants, and municipal projects, these units incorporate intelligent control systems enabling automatic start/stop, constant-pressure water supply, and fault alarms. They ensure rapid response and continuous water delivery during fires, providing reliable fire safety assurance.

The vertical multi-stage in-line fire pump unit is a highly efficient water supply system designed specifically for fire protection systems in high-rise buildings, industrial plants, municipal projects, and large commercial complexes. Its compact structure, stable operation, high head, and low noise make it an indispensable component of modern fire protection systems. Using a vertical multi-stage centrifugal pump as its primary water supply source, combined with a scientific piping layout and automatic control system, this pump unit delivers continuous, stable, and precise pressure water supply, ensuring rapid and sufficient firefighting water supply in the event of a sudden fire, thus providing reliable protection for building fire safety. The vertical multi-stage in-line fire pump unit features a vertical design with the pump body and motor coaxially mounted, resulting in a small footprint and compact structure for easy installation and maintenance, making it ideal for space-constrained equipment rooms. The pump body is constructed of high-quality cast iron or stainless steel for strong corrosion resistance, ensuring long-term stable operation in complex water conditions. The impeller utilizes an optimized hydraulic model design, resulting in a smoother flow and head performance curve, high efficiency, and minimal hydraulic losses, ensuring high head output while achieving energy-saving operation. In addition, the pump shaft undergoes precision dynamic balancing, coupled with high-quality bearings and a mechanical seal structure, ensuring smooth operation, low noise, and minimal vibration, extending the equipment’s service life. One of the greatest advantages of this pump unit is its high energy efficiency. By utilizing advanced fluid dynamics and a multi-stage tandem impeller structure, it achieves higher head output with lower energy consumption, meeting the fire water supply requirements of multi-story and super-high-rise buildings. Combined with a variable frequency control system, the operating speed automatically adjusts according to system pressure, ensuring on-demand water supply and minimizing energy waste. The intelligent control system offers multiple functions, including automatic start and stop, pressure monitoring, flow regulation, and fault alarms. Upon detecting a pressure drop or triggering a fire alarm, the pump unit automatically activates, ensuring immediate response to firefighting needs and significantly improving emergency response efficiency. The vertical multi-stage in-line fire pump unit is manufactured with meticulous attention to process precision and structural optimization. The streamlined design of the pump body and flow guide components effectively reduces flow resistance and hydraulic losses, improving overall efficiency. The shaft seal utilizes a mechanical seal structure, offering excellent sealing performance and wear resistance, preventing leaks and ensuring long-term stable operation. The motor utilizes a high-efficiency, energy-saving motor with a high degree of protection and excellent insulation performance, enabling stable operation in high-temperature, humid, and dusty environments. The pump unit’s reinforced base is designed to withstand long-term vibration and shock, ensuring overall system safety and stability. Its unique vertical multi-stage design provides high head and pressure output, making it ideal for high-rise buildings, sprinkler systems, fire hydrant systems, and various fire water supply systems, such as water curtains and foam systems. Its multi-stage impeller gradually increases pressure, ensuring stable flow and sufficient pressure even over long distances and on high floors. Furthermore, the pump unit achieves constant pressure control during operation, preventing water hammer caused by pressure fluctuations in the pipeline network, thereby protecting system pipes and valves and extending the service life of the entire fire protection system. The vertical multi-stage in-line fire pump unit is also extremely easy to install and maintain. Its vertical design occupies only one-third the floor space of a horizontal pump, making it ideal for use in basements or equipment rooms where space is limited. The inlet and outlet are aligned horizontally, facilitating direct connection to pipelines without the need for additional adjustments. Upon installation, the unit features automatic exhaust and self-priming functions, reducing manual operation time and improving system reliability. Routine maintenance requires only regular checks of the motor’s operating status, shaft seal, and lubrication system, significantly reducing maintenance costs. This pump unit also offers exceptional adaptability and flexibility, allowing customization to meet diverse project requirements. For example, motor and impeller combinations of varying power can be configured to meet the fire system’s design flow and head requirements. It can also be equipped with various control methods, such as electric, variable frequency, or automatic, enabling multiple operating modes. For locations requiring high reliability, it can be combined with a diesel engine pump unit and a pressure-stabilizing pump to create a complete fire pump system, achieving dual-power redundancy and ensuring a stable water supply under all conditions. This vertical multi-stage in-line fire pump unit not only delivers exceptional performance but also meets international safety standards. All key components undergo rigorous strength, pressure resistance, and sealing tests to ensure long-term, stable operation under high-pressure conditions. The system incorporates multiple protection mechanisms, including overload, phase loss, overheating, and low-pressure alarms, which automatically shut down or sound an alarm in the event of an abnormality, preventing damage to the equipment. Select models also support remote monitoring and intelligent management, allowing users to view the pump unit’s operating status in real time via a control panel or network system, enabling remote operation and maintenance. In firefighting applications, time is of the essence. Vertical multi-stage in-line fire pump units are designed with “rapid response and stable water supply” as their core goals. When the system detects a pressure drop or a fire signal is triggered, the pump unit automatically starts and enters full-load operation within seconds, ensuring that the fire sprinkler or fire hydrant system receives sufficient water pressure immediately, buying valuable time for firefighting. Furthermore, its constant-pressure water supply ensures stable pipe pressure even with simultaneous water use at multiple points, without compromising firefighting efficiency. In addition to firefighting systems, this pump unit can also be used in building water supply, industrial circulating water systems, cooling water systems, and air conditioning systems, offering a “one-machine-multi-purpose” solution. Its high head and high efficiency make it particularly advantageous in high-rise buildings and long-distance water supply, meeting the continuous operation requirements of various complex operating conditions. Each unit undergoes rigorous factory testing to ensure that each pump meets excellent standards for performance, noise, vibration, and sealing. In the future, with the growing trend toward intelligent and energy-efficient systems, vertical multi-stage in-line fire pump units will continue to upgrade towards higher efficiency, smart functionality, and greener environmental performance. By incorporating IoT technology and remote monitoring systems, these units can collect real-time data and analyze operating status, providing early warning of potential failures, reducing maintenance risks, and extending service life. The application of intelligent variable frequency control technology not only enhances the system’s energy efficiency but also enables the pump unit to automatically adjust its operating state under varying workloads, consistently maintaining an efficient operating point, further reducing energy consumption and operating costs. Overall, vertical multi-stage in-line fire pump units, with their combined advantages of high head, high efficiency, compact design, reliable operation, and energy-saving and environmentally friendly performance, have become the preferred equipment for modern fire water supply systems. Whether in high-rise residential buildings, commercial buildings, industrial parks, or municipal public facilities, they provide fire protection systems with a continuous, stable, and high-pressure water supply, ensuring rapid response and stable water supply in emergencies, providing a solid foundation for building safety. This type of pump unit not only embodies advanced manufacturing processes and fluid dynamics design concepts, but also represents the future trend of intelligent, safe, and energy-efficient firefighting equipment.