Multifunctional Diesel Fire Pump Set: Enhancing Safety in Fire Protection Systems

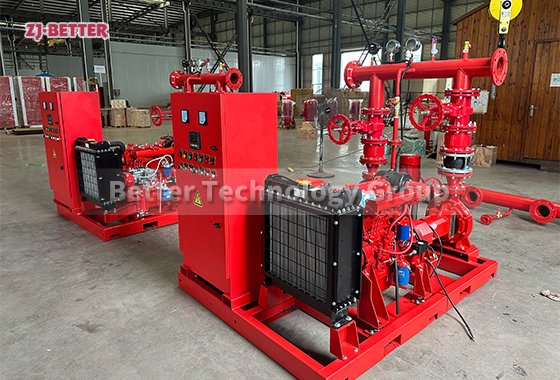

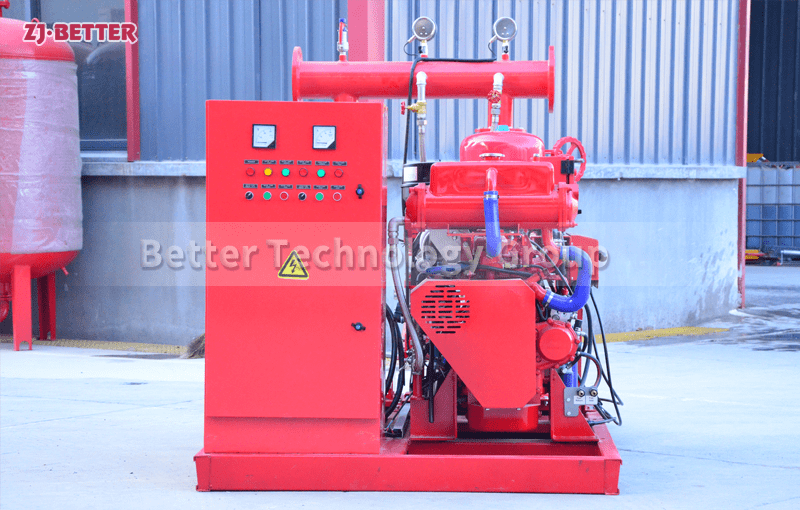

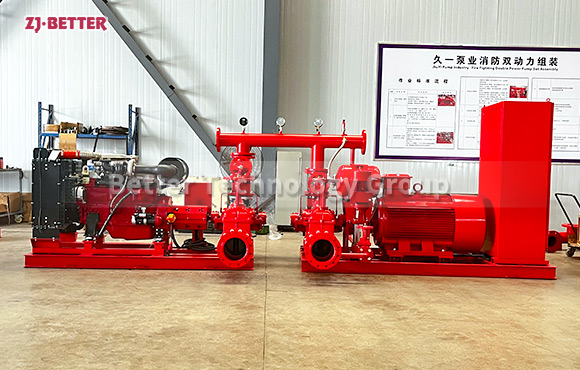

The multifunctional diesel engine fire pump unit has the advantages of independent power, fast start-up, efficient water supply, durable stability and intelligent control. It is suitable for high-rise buildings, industrial parks, chemical plants, municipal projects and emergency disaster prevention scenarios, ensuring reliable fire water supply during power outages or complex environments.

As the core equipment in modern fire protection systems, multifunctional diesel fire pump sets play an irreplaceable role in the fire emergency water supply link. This type of equipment relies on diesel engines as power to drive the water pump, avoiding the problem of failure to start in the case of insufficient power supply or power system interruption, and ensuring continuous and stable water supply at critical moments. It can be widely used in industrial parks, chemical companies, high-rise buildings, airports, stations, oil depots, docks and municipal water supply and drainage projects. With multiple advantages such as compact structure, strong power, wide adaptability, stable operation and convenient maintenance, it has become an important guarantee for improving the reliability of fire protection systems. Especially in occasions with extremely high requirements for water supply continuity, stability and durability, diesel fire pump sets have demonstrated their unique performance value. First of all, it has outstanding advantages in independent energy supply. Compared with electric fire pumps that rely on mains electricity, diesel engine-driven pump sets are completely unrestricted by the power grid and can still start and operate normally in the case of power outages, power outages or severe power fluctuations. This independence is particularly important when a fire occurs, because fires are often accompanied by power outages, and the fire protection system must ensure water supply in the first place. Therefore, the diesel engine pump set ensures the life of the entire fire protection system with independent power. line, and secondly, it exhibits fast and reliable characteristics in terms of starting performance. The diesel engine is designed with two modes: automatic start and manual control. When the fire alarm signal is triggered, the equipment can complete self-test and start within seconds, and quickly put the water pump into operation to ensure uninterrupted water supply on site. At the same time, the intelligent control system can monitor key operating parameters such as speed, oil pressure, water temperature, pump pressure in real time, effectively avoiding fault shutdown caused by abnormal operation, and improving the stability and safety of the overall system. Moreover, its flow and head range covers a wide range, and the appropriate model can be selected according to different project needs, meeting the needs of high-pressure water supply from high-rise buildings to The pump body is designed to optimize the hydraulic performance to ensure the operation in a high-efficiency state and reduce energy and fuel consumption. This can significantly reduce the operating cost for long-term users. In terms of durability and adaptability, the diesel fire pump group is made of high-strength wear-resistant materials, with good corrosion resistance and shock resistance. It can adapt to complex and harsh environmental conditions such as high temperature, low temperature, humidity, dust and salt spray, ensuring long-term stable operation without external influence. In addition, the overall layout of the equipment is reasonable, the maintenance space is sufficient, and the repair and maintenance operations are convenient, which can effectively reduce the cost of the pump. Low labor and time costs during use, its flexibility is also reflected in the customizable design. Whether it is a single-machine driven pump unit or a complete integrated system, it can be tailored according to the user’s engineering needs. For example, it can be configured with a dual power switching system, automatic heating device, soundproof chassis, rain cover, base oil tank and other diversified options to enhance the adaptability under different working conditions. This highly flexible configuration capability makes it widely used in the global market. In addition to conventional fire water supply, diesel engine pump units are also commonly used in municipal emergency drainage, flood prevention and rescue, industrial cooling and other scenarios, reflecting the multifunctional value. From the perspective of reliability Analysis shows that diesel engine pump sets are usually designed with redundant systems, such as dual battery starting, automatic heating maintenance, oil pressure and water temperature dual protection, etc., to ensure that they can still be started with one button in cold environments or long-term standby state, and truly be on standby at any time, thus providing users with a sense of security and trust. In terms of operation and control, modern diesel engine pump sets are generally equipped with intelligent control panels that support automatic monitoring and remote operation. Users can grasp the operating status of the equipment in real time through the centralized control platform. Some systems can even realize remote alarm and data transmission, which greatly improves the operation and maintenance efficiency and system response speed, which not only reduces the cost of human labor, but also reduces the maintenance cost. In terms of environmental protection and energy saving, the diesel engine fire pump set significantly improves fuel utilization and reduces exhaust emissions and noise pollution by optimizing the combustion system and hydraulic component design. At the same time, some units can also be equipped with silencers and environmentally friendly coatings to meet the requirements of green energy conservation and environmental protection in modern society. This is especially important for pump sets that operate in residential areas or densely populated areas for a long time. From the above advantages, it can be seen that the multifunctional diesel engine fire pump set is not only a fire-fighting equipment, but also a reliable, safe and efficient emergency water supply solution. With its independent power system, fast starting performance, strong water supply capacity, excellent environmental adaptability, flexible customization function and intelligent control system, it meets the stringent requirements of fire water supply under various complex working conditions and plays a vital role in protecting the safety of life and property. In the future, with the continuous improvement of fire protection standards and the diversification of application scenarios, diesel engine fire pump sets will surely be further optimized in design, improve energy saving and environmental protection performance, and strengthen integration with intelligent fire protection systems to achieve a higher level of safety protection and provide more reliable fire water supply guarantees for users around the world.