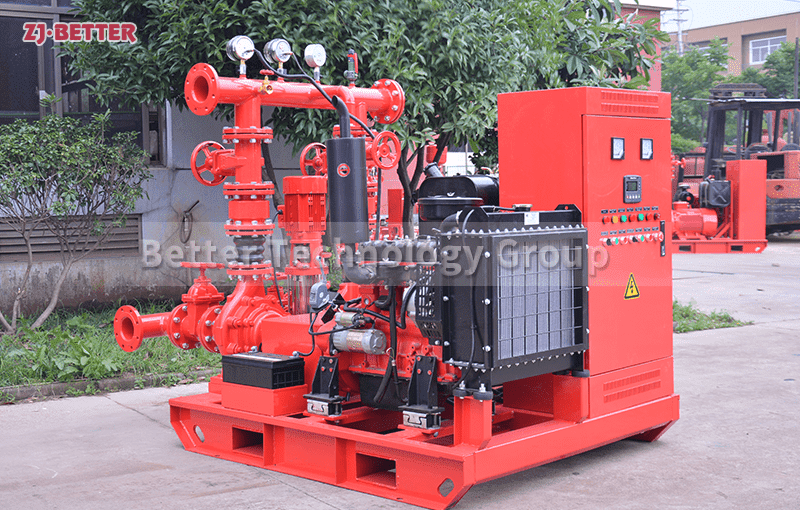

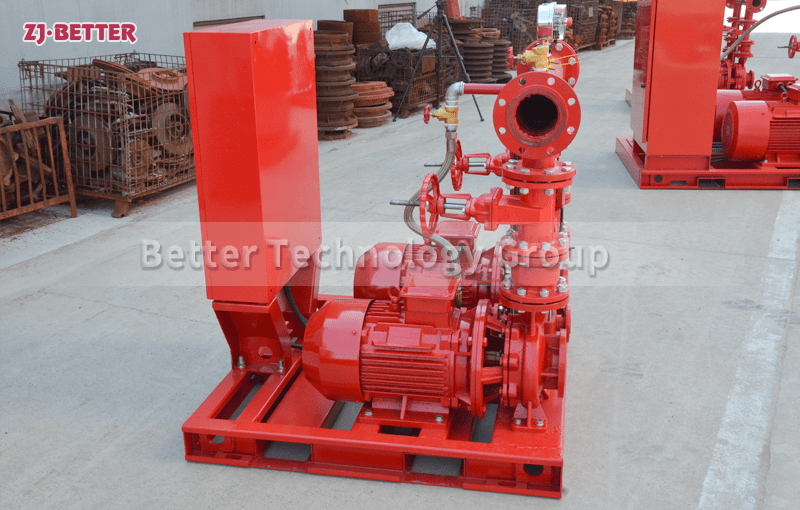

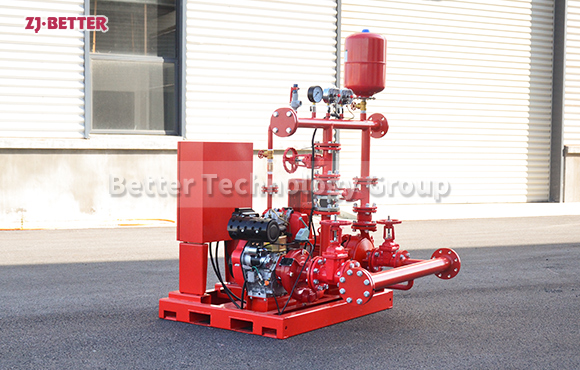

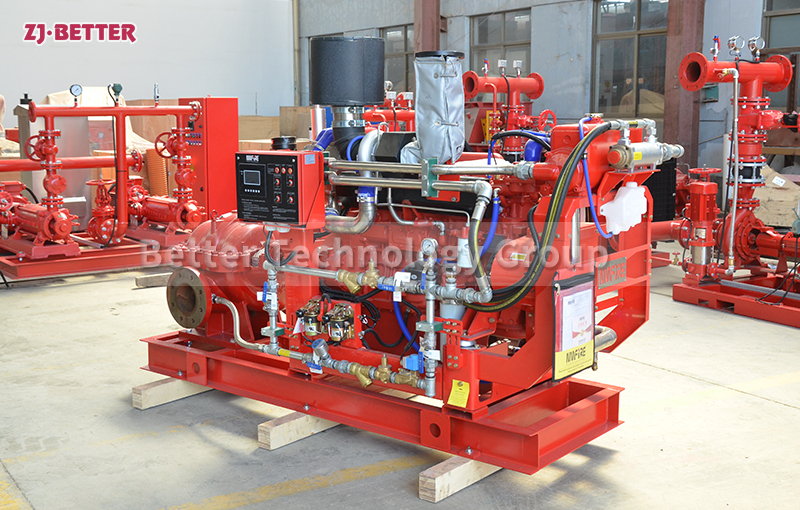

Integrated Fire Pump System: Reliable Water Pressure for Building Safety

The integrated fire pump system, with its integrated structure and intelligent control technology at its core, integrates a pump unit, control cabinet, piping, and pressure-stabilizing equipment. It offers high efficiency, energy savings, easy installation, and reliable operation. Suitable for a variety of locations, including high-rise buildings, industrial plants, and commercial complexes, it provides rapid water supply in the event of a fire, ensuring fire safety and stable system operation. It is an ideal fire water supply solution for modern buildings.

Integrated fire pump systems are key equipment for ensuring efficient and reliable water supply in modern buildings and various industrial facilities. They integrate pump units, control systems, piping, valves, pressure tanks, and auxiliary equipment onto a single platform. Through modular design and automated control, they achieve efficient, safe, and intelligent operation of fire water supply systems. With the acceleration of urbanization and the continuous improvement of building safety standards, integrated fire pump systems have gained widespread adoption in high-rise buildings, commercial complexes, factory workshops, warehouses, and public facilities. They not only provide sufficient firefighting water immediately upon fire, but also ensure long-term stable operation, providing a solid foundation for overall building safety. The system’s greatest advantage lies in its integrated design. Traditional fire pump systems typically require separate installation of the pump, electrical control cabinet, voltage regulator, and piping system, resulting in large footprints, long installation cycles, complex connections, and difficult maintenance. The integrated design, on the other hand, centralizes all key components within a single chassis or cabinet, resulting in a more compact equipment layout and a smaller footprint, significantly saving installation space and construction costs. All components undergo rigorous factory assembly and commissioning. Users only need to connect the inlet and outlet pipes and power supply on-site for immediate operation, significantly shortening the installation cycle and avoiding performance losses caused by on-site installation errors. The integrated fire pump system utilizes an energy-efficient pump body design, resulting in smooth flow and high hydraulic efficiency. The pump unit operates stably and consumes low energy under rated operating conditions. The drive system can be configured with either an electric motor or a diesel engine, or a dual-power system, ensuring reliable fire water supply in all conditions. Electric motor operation offers smooth, low-noise operation, making it suitable for everyday use. Diesel engine operation automatically activates in the event of a power outage or grid failure, ensuring continuous water supply and significantly enhancing the safety and redundancy of the entire fire protection system. The control system is the core of the integrated fire pump system. It utilizes intelligent automatic control technology to monitor and adjust the pump unit’s operating status in real time. The control cabinet integrates multiple sensing devices, including pressure sensors, flow switches, level controllers, and temperature detectors. It automatically detects changes in system pressure and activates the appropriate pump unit, enabling automatic switching between the main pump, pressure-stabilizing pump, and backup pump. When the system detects a drop in pipe network pressure or a sprinkler system activation signal, the controller immediately initiates a command to activate the main pump to ensure adequate water supply. Once the fire alarm is resolved or the pressure returns to the set value, the system automatically shuts down and enters standby mode, requiring no human intervention. This fully automated operation significantly improves system response speed and effectively eliminates the risk of human error. To ensure long-term, reliable operation in diverse environments, all components of the integrated fire pump system are manufactured from high-quality materials. The pump body is typically constructed of high-strength cast iron or stainless steel, offering excellent corrosion and wear resistance, maintaining stable performance in impurities, high temperatures, and high pressures. The sealing system utilizes mechanical or composite seals to effectively prevent leaks and extend service life. The control cabinet’s internal wiring is rationally arranged, and the power distribution system’s moisture- and dust-resistant design ensures stable operation in harsh environments such as high humidity, high temperatures, and dust, ensuring stable operation outdoors or in semi-enclosed spaces. The system also excels in energy control and energy conservation. Using an intelligent pressure control algorithm, the system automatically adjusts the pump speed based on the real-time pipe network pressure, avoiding energy waste caused by frequent starts and stops. At the same time, the pressure-stabilizing pump maintains the basic pressure of the pipeline network in the non-fire alarm state, and the main pump is only started when a fire occurs, thereby significantly reducing daily operating energy consumption. For buildings that need to be on standby around the clock, this energy-saving control method can save a lot of electricity expenses and is also in line with the current development trend of green buildings and energy conservation and environmental protection. In addition to its superior performance, the integrated fire pump system also has significant advantages in maintenance and management. Due to the modular design of the equipment, the installation position of each component is clear and the structure is compact, which is convenient for maintenance and replacement. The system has fault self-detection and alarm functions. When the pump group is overloaded, under-voltage, over-temperature or the flow is abnormal, the control system will automatically alarm and record the fault information, so that technical personnel can promptly troubleshoot the problem. Some systems also support remote monitoring, and can transmit operating data to the monitoring center in real time through the communication module, realizing centralized management of multiple devices, greatly improving the intelligent level of system operation and maintenance. This system is applicable across a wide range of applications, from residential communities and office buildings to shopping malls, airport terminals, subway stations, and industrial sites such as petrochemical plants, power stations, and storage and logistics parks. Pumps with varying flow rates, lifts, and control modes can be flexibly configured to meet various fire regulations. For buildings with limited space, such as basements, equipment rooms, or temporary construction areas, the integrated fire pump system, with its compact design and quick installation, is an ideal fire water supply solution. Furthermore, it seamlessly integrates with a variety of fire protection systems, including sprinkler systems, fire hydrant systems, and foam fire extinguishing systems, to create a complete fire water supply network. Safety is a core design consideration. All electrical components are certified to international safety standards and feature multiple safety features, including short-circuit protection, overcurrent protection, and undervoltage protection. The control logic incorporates a manual/automatic dual-mode switchover function. If the automatic control system experiences an anomaly, the pumps can be manually started and stopped, ensuring continued fire water supply in emergencies. Furthermore, the system features dry-run and backflow protection, effectively preventing pump damage and water contamination, enhancing overall safety. With the development of smart fire protection and IoT technologies, integrated fire pump systems are gradually becoming intelligent. The new generation of products enables data monitoring and remote control via cloud platforms, providing real-time visibility into the operating status of equipment in each area, enabling preventive maintenance and intelligent scheduling. This technological integration not only improves equipment efficiency but also makes fire management more scientific and efficient. In summary, the integrated fire pump system, with its integrated structure, intelligent control, high-efficiency operation, and excellent reliability, has become an indispensable component of modern building fire protection systems. It offers significant advantages in space savings, reduced energy consumption, improved safety, and simplified maintenance, making it an ideal choice for addressing various fire risks and ensuring building safety. Whether in industrial applications or civil engineering, this system has earned widespread recognition for its advanced technical performance and reliable operation, providing strong technical support for modern fire safety.