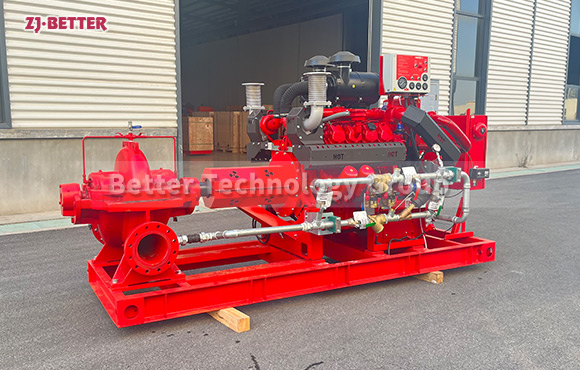

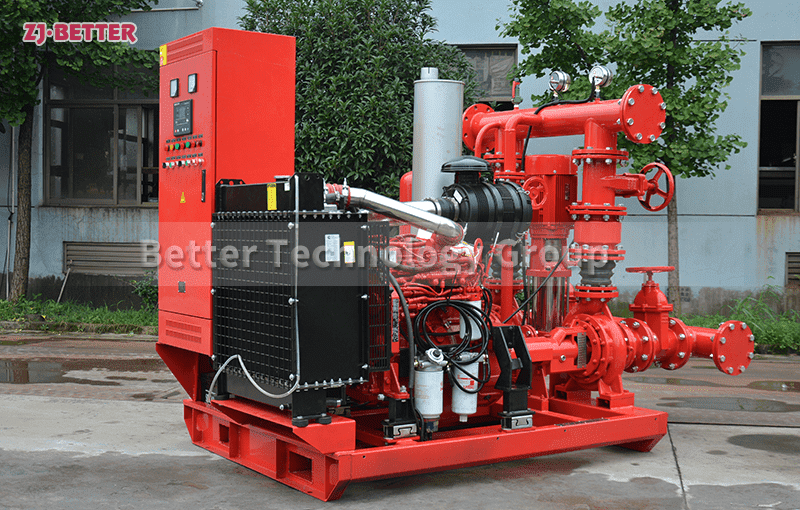

Flexible and Efficient Dual Pump System for Multi-Scenario Firefighting Water Supply Needs

The diesel-driven dual-pump system features efficient water flow output, strong adaptability, and energy-saving design. It is suitable for high-pressure firefighting needs in high-rise buildings, industrial parks, and other areas. It ensures stable water supply, provides flexible deployment, and high reliability, making it an ideal choice for emergency firefighting.

In modern firefighting systems, water source reliability and supply capacity are crucial factors in determining firefighting success. Especially in complex fire environments, the stability, flexibility, and continuity of the water supply system are crucial. Dual-pump systems, particularly diesel-powered dual fire pump units, have become indispensable components of emergency firefighting systems due to their robust water supply capacity, flexible deployment, and efficient operation. This system utilizes a dual-pump parallel design, enabling higher flow rates and head, ensuring a continuous and sufficient water supply during fire emergencies. It is particularly suitable for industrial areas, high-rise buildings, chemical plants, and remote locations far from municipal water supplies. The dual-pump parallel design offers exceptional flexibility and efficiency, meeting diverse needs in a variety of scenarios and improving firefighting efficiency. By utilizing two independent pumps working together within the same system, this system not only delivers higher flow rates but also allows for flexible switching between pumps based on demand, ensuring a balanced and stable water supply. In large buildings and industrial parks, a single pump may not be able to simultaneously supply water to multiple areas. A dual-pump system allows for rapid start-up and shutdown based on on-site needs, improving firefighting efficiency and ensuring water supply to each firefighting point. Compared to electric pumps, diesel-engine-driven dual-pump systems offer greater independence and reliability. Even during power outages or unstable electricity, the diesel engine can provide continuous power, ensuring the firefighting system can operate normally in any environment. This makes diesel-engine-driven fire pump systems particularly suitable for areas lacking stable power sources, such as industrial plants, mining areas, and oil fields, or for providing emergency water supply independent of the municipal power grid during natural disasters. Powered by a highly efficient diesel engine, these pumps operate stably at high flow rates and high lifts, meeting the demands of firefighting. The dual-pump parallel design not only improves water supply capacity but also enhances the redundancy and stability of the firefighting system. By operating the two pumps in parallel, even if one fails, the other continues to operate, ensuring an uninterrupted firefighting water supply. Furthermore, in the event of a pump failure or scheduled maintenance, the other pump can serve as a backup, significantly reducing the risk of downtime and improving the reliability and safety of the entire firefighting system. The dual-pump system’s efficiency and energy efficiency are also significant advantages. In practice, fire pump systems often require extended periods of standby time, especially in high-rise buildings and storage areas. Stable firefighting system operation is crucial for ensuring personnel safety. A dual-pump system, operating in parallel, can adjust flow and head according to actual needs, avoiding unnecessary energy waste. Compared to traditional single-pump systems, the dual-pump parallel design achieves higher efficiency, ensuring adequate water flow while reducing energy consumption and maintenance costs. This energy-saving effect is particularly suitable for firefighting systems operating over a long period of time, significantly reducing operating costs and providing users with a more cost-effective solution. For locations requiring high pressure and high flow rates, such as high-rise buildings and industrial parks, dual-pump systems provide a strong and continuous water flow, ensuring smooth firefighting operations. Compared to traditional single-pump systems, dual-pump systems deliver higher water pressure and flow, meeting the needs of high-pressure sprinkler systems, fire hydrant systems, and other firefighting equipment. This allows for rapid extinguishing of fires at their earliest stages and effectively preventing their spread. Furthermore, dual-pump systems enable multi-point water supply, providing water to multiple firefighting points within a building, eliminating the ineffective firefighting caused by insufficient water supply in single-pump systems. The diesel-powered dual-pump system offers exceptional durability and adaptability, making it particularly suitable for use in industrial environments and harsh conditions. Fire pumps often operate for extended periods, especially in high-risk fire zones, making their durability and environmental resistance crucial. The diesel-powered system, through optimized design and the use of high-strength materials, ensures stable operation in complex environments such as high temperature, high humidity, high dust levels, and chemical corrosion. The pump body and engine are constructed of high-temperature and corrosion-resistant alloys, ensuring long-term stability and service life, enabling efficient operation even in demanding operating environments. This durability significantly reduces the frequency of repairs and replacements, lowering maintenance costs and improving the cost-effectiveness of the equipment. To enhance the intelligence of the dual-pump system, modern fire pump sets are equipped with intelligent control systems that monitor the equipment’s operating status and operational data in real time. This intelligent control system allows operators to monitor pump flow, pressure, current, temperature, and other parameters at all times, ensuring optimal operation. The system’s built-in fault detection and alarm functions provide timely alerts when an abnormality occurs, automatically initiating protective measures and shutting down the system to prevent further failures. Furthermore, the intelligent system enables remote operation and monitoring. Users can remotely view the equipment’s operating status via mobile phones, computers, and other devices and make adjustments as needed, significantly improving fire management efficiency. The dual-pump system’s maintainability and operability have also been optimized. The system design incorporates the need for regular inspections and rapid maintenance. Key components such as the pump body, diesel engine, and fuel tank are easily removable and replaceable, facilitating routine maintenance and upkeep. The modular design simplifies equipment maintenance, reduces downtime, and improves maintenance efficiency, ensuring the long-term stability of the firefighting system. In summary, the diesel-powered dual-pump system, with its efficient water output, reliable power support, strong adaptability, and energy-saving design, has become an indispensable firefighting equipment in a variety of emergency scenarios. It provides a continuous and efficient water supply, meeting the high-pressure requirements of high-rise buildings, industrial parks, chemical plants, and other locations, playing a vital role in ensuring fire safety and minimizing losses. With the continuous advancement of firefighting technology, future dual-pump systems will become even more intelligent, energy-efficient, and environmentally friendly, providing the firefighting industry with more efficient and reliable solutions, ensuring an uninterrupted water supply in any fire emergency.