The Key to Emergency Response Efficiency: A Modular Diesel Fire Pump System in Focus

The modular diesel fire pump unit integrates diesel power, intelligent control, and high-efficiency pumps, making it a key solution for improving fire response efficiency and system reliability in high-rise buildings, chemical storage, and emergency scenarios.

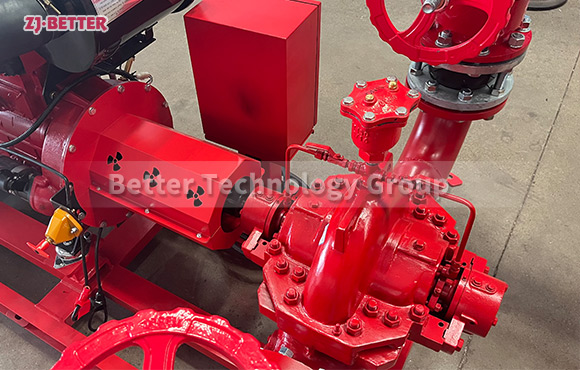

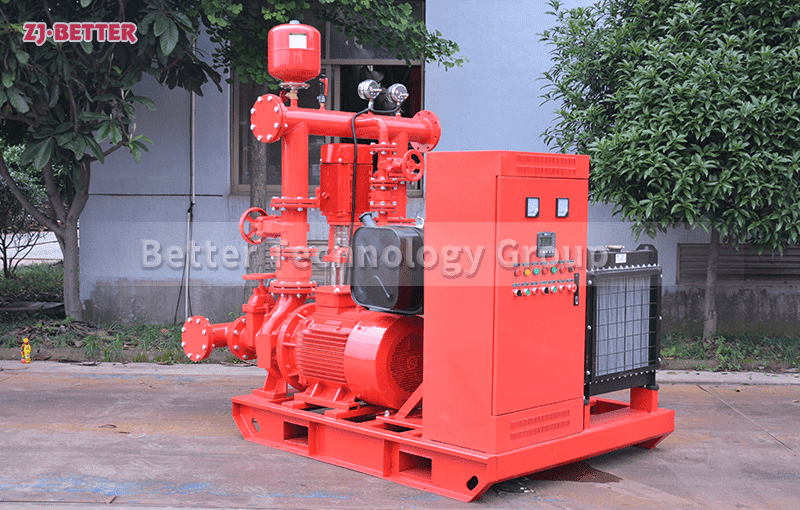

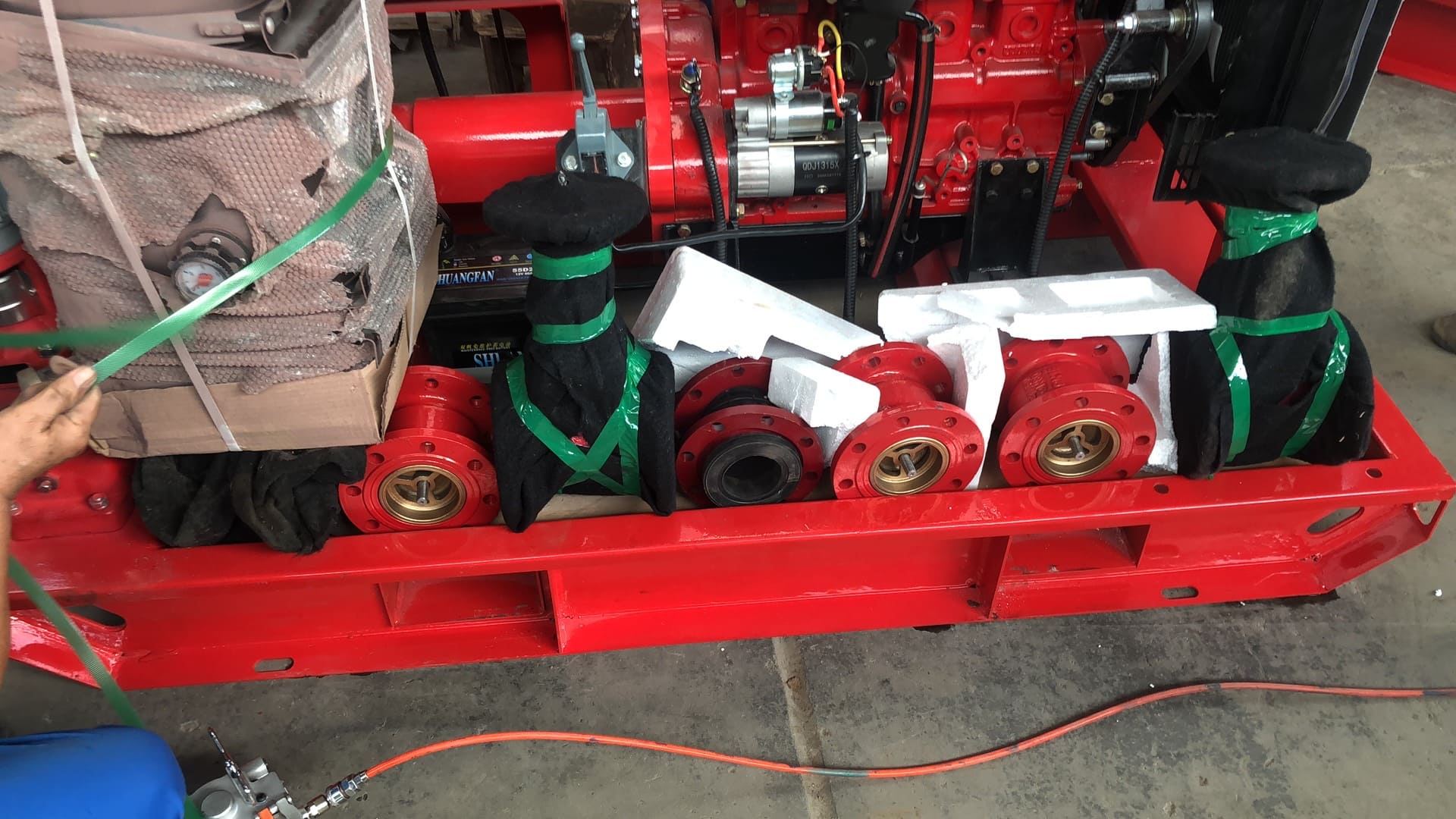

As an indispensable part of modern fire protection systems, modular diesel fire pump units have emerged as the preferred choice for critical infrastructure such as large-scale industrial plants, commercial complexes, petrochemical storage facilities, and transportation hubs. Their core advantages include high integration, fast emergency startup, and adaptability to extreme environments. By integrating diesel engine power systems, high-efficiency centrifugal pumps, intelligent control panels, fuel supply modules, cooling and exhaust systems, and pre-charged pressure tanks into a single assembly, these units significantly improve the on-site deployment efficiency and operational reliability of fire safety systems. Critically, they operate independently of the power grid, providing rapid activation in emergencies—particularly valuable during power outages, earthquakes, and extreme weather events. At the heart of this modular system lies the diesel engine, which is often sourced from globally renowned manufacturers such as Cummins, Weichai, Shangchai, or Deutz. These engines are known for their robust power output and durability. The engine connects to the pump via high-strength couplings to ensure efficient and stable power transmission. An intelligent control panel enables fully automatic start-stop control, parameter monitoring, alarm systems, and fault protections, reducing manual intervention. The pump structure adopts either single-stage or multi-stage centrifugal configurations. The hydraulic components are made of materials like ductile iron, stainless steel, or bronze, tailored to suit environments involving clean water, impurity-laden water, or high-temperature fluids. The flow rate and head range from 0-200L/s and up to 250 meters, making it suitable for high-rise buildings and long-distance fire water supply applications. The structural layout emphasizes transportability and ease of installation. Mounted on a high-strength steel skid base, the engine, pump, control unit, silencer, fuel tank, and pre-installed pipework and cables are compactly arranged for quick installation. This plug-and-play setup significantly reduces on-site commissioning time and boosts construction efficiency. The intelligent control cabinet features automatic start, remote monitoring, historical data logging, audible and visual alarms, and RS485 communication capabilities. It seamlessly integrates with centralized monitoring systems in pump rooms or fire control centers, thus elevating the level of automation and operational oversight. Real-time diagnostics of fuel level, coolant temperature, exhaust temperature, and battery voltage, combined with emergency shutdown functions, ensure comprehensive operational safety. Additionally, a pressure maintenance subsystem, often powered by an auxiliary electric pump, ensures consistent baseline pressure in the fire network. This prevents unnecessary main pump activation and helps reduce energy consumption, highlighting the system’s energy-efficient design. From a manufacturing standpoint, modular diesel fire pump units are produced using advanced technologies such as laser cutting, CNC bending, robotic welding, and powder coating. The equipment features a clean appearance, excellent rust protection, and consistent quality. All critical seals and components are sourced from premium international suppliers, ensuring a minimum of ten years of reliable operation. Furthermore, the unit can be customized to meet diverse client specifications, including coating color, explosion-proof levels, anti-corrosion standards, control logic, and communication protocols, complying with international and regional regulations. In fire drills and real emergency scenarios, these modular diesel units have consistently demonstrated their rapid response capabilities, operational stability, ease of maintenance, and long service life. Whether deployed in airport fueling zones, tunnel systems, chemical storage yards, or high-rise urban buildings, they ensure reliable water supply at critical moments, forming the core pumping infrastructure that underpins the resilience of urban firefighting systems. In summary, modular diesel fire pump units represent more than a technical upgrade from traditional systems—they exemplify the fusion of advanced fire safety concepts with modern automation. With unparalleled integration, fast response, intelligent control, and flexible deployment, they have become essential assets in the fire safety strategies of high-risk environments. As global infrastructure continues to evolve toward greater complexity and smart capabilities, the demand for such modular systems will only grow, cementing their position as a cornerstone in the future of firefighting technology.