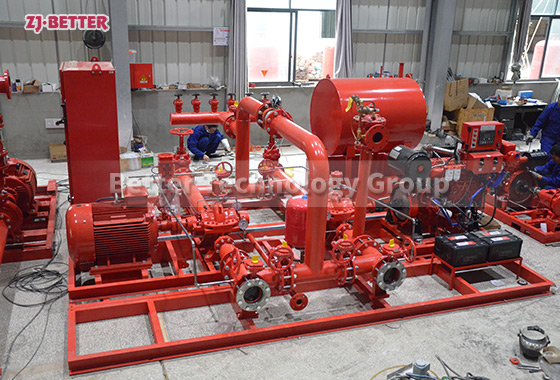

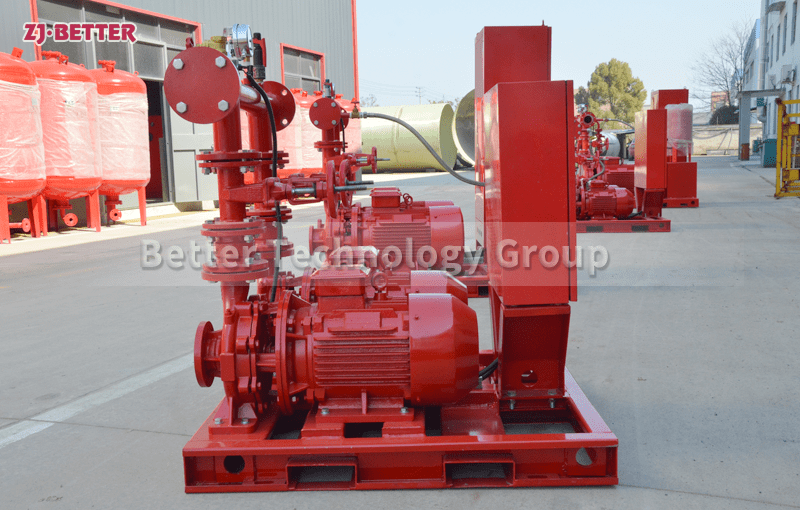

Fully-Enclosed Diesel Fire Pump System: Reliable Protection in Harsh Environments

Fully enclosed diesel fire pump system designed for harsh environments, offering superior sealing, dustproofing, noise reduction, and corrosion resistance—ideal for petrochemical, warehousing, and port applications with reliable and efficient fire protection.

In numerous industrial applications and special scenarios, the stability and environmental adaptability of fire pump systems directly impact the safety of personnel and assets on-site. The fully enclosed diesel fire pump system is specifically designed for such high-demand environments, with its design philosophy focusing not only on high-performance output but also emphasizing long-term adaptability to extreme operating conditions and operational reliability.

The equipment features a modular fully enclosed structural design, with key components such as the pump body, diesel engine, and control system fully enclosed within a dedicated steel soundproof enclosure. This significantly reduces operational noise and effectively isolates external environmental disturbances such as dust, rain, snow, high temperatures, or low temperatures, ensuring the equipment can still start efficiently and operate reliably under harsh conditions. This structure is particularly suitable for harsh application scenarios such as chemical plants, coastal ports, mining areas, warehousing bases, airports, and remote areas without electricity.

The fully enclosed system is equipped with a high-performance industrial-grade diesel engine, offering excellent fuel efficiency and high-temperature vibration resistance, maintaining stable output even under continuous high-load operation. The high-efficiency centrifugal pump body is made of corrosion-resistant materials and undergoes special surface treatment, making it suitable for conveying media containing corrosive particles or seawater components, significantly expanding the equipment’s application range.

The control system integrates intelligent monitoring, automatic alarms, remote control, and data recording functions. Through a PLC programmable logic controller, it manages engine speed, water pressure flow, battery status, temperature, and operating time in real-time, ensuring operators can monitor system status and respond quickly to abnormalities at any time. The system also supports backup power startup and automatic switching, ensuring that the pump unit can still start and run independently in the event of a power outage.

From a structural strength perspective, the entire pump unit base is manufactured using heavy-duty welding technology, offering strong load-bearing capacity and resistance to vibration and impact. Elastic vibration-damping pads are installed between the base and the unit, effectively eliminating vibration transmission to the foundation during operation, thereby extending the overall service life of the equipment. The outer casing surface is coated with a high-temperature baked paint finish, offering corrosion resistance, UV protection, and mold prevention. It can withstand prolonged exposure to high humidity and strong UV environments without fading or peeling.

In terms of installation and maintenance, the system design prioritizes user convenience. The enclosed housing features multiple quick-access doors and maintenance windows, allowing technicians to easily inspect, replace filters, or perform routine maintenance on components such as the diesel engine, pump body, and control cabinet. The bottom of the housing is pre-equipped with lifting holes and forklift slots for quick positioning and movement on construction sites.

From a safety protection perspective, the fully enclosed system complies with multiple international fire safety standards. Built-in sensors continuously monitor the operational status of the unit. In case of abnormal conditions (such as low oil pressure, high water temperature, or insufficient fuel), the system automatically triggers audible and visual alarms and implements corresponding control measures, significantly enhancing operational safety.

In terms of emergency response efficiency, the system features a quick-start function, with conventional cold start times controlled within 15 seconds. In hot standby mode, it can achieve instant ignition startup, meeting the stringent requirements for response speed in sudden fire incidents. Its rapid pressure-building system can establish stable pipeline pressure in an extremely short time, providing robust hydraulic support for sprinkler, hydrant, and foam systems.

Overall, the fully enclosed diesel fire pump system, with its outstanding structural sealing performance, operational stability, and intelligent control advantages, has become the preferred fire protection power solution for industries such as industrial, petrochemical, military energy storage, and large-scale logistics warehousing. It not only ensures fire protection reliability in high-risk environments but also reduces users’ operational and maintenance costs throughout the system’s lifecycle with its efficient, low-maintenance, and long-lasting system characteristics.

.jpg)

.jpg)