ED Small Fire-fighting Complete Set of Water Supply Equipment

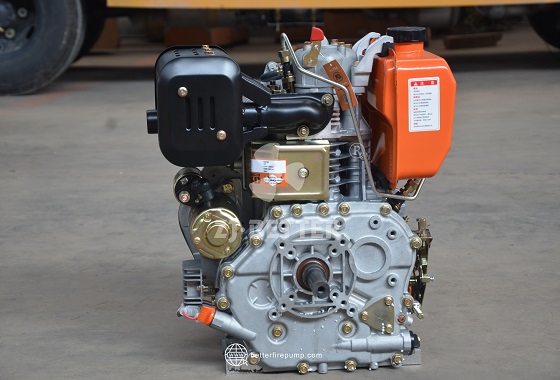

ED small fire pump set (referred to as ED small fire complete set of water supply equipment) refers to a highly integrated electromechanical system with a flow rate of less than 100GPM and composed of electric centrifugal pumps, multi-stage centrifugal pumps (booster pump sets), diesel engine centrifugal pumps, pressure limiting protection Device (safety valve), valve fittings, control system, pressure sensor system, waterless protection device, backflow preventer, soft joint, bypass pipeline, common base, filter, etc. It is a fire-fighting water supply equipment that continuously supplies water to the fire-fighting pipe network at a preset pressure.

When the pressure in the fire extinguishing system pipeline of the ED small fire water supply equipment suddenly drops, the pump starts to work. The first trigger pump is the stabilizing pump (stabilized pump). The stabilized pump stabilized pipeline is allowed to start frequently within a certain range. Generally, the pressure of the jockey pump is 1-1.5 bar higher than the pressure of the main pump.

If the pump still fails to reach the preset pressure level (down to the preset pressure of the main pump), the main pump will start. When there are multiple main pumps, the pumps are started in series according to the different pressure levels set by the starting pressure switch. The pressure switch of the main pump is not only used for starting (if the main pump cannot be stopped automatically, it needs to be stopped manually when NFPA20 is satisfied), but it can also be stopped automatically.