The Ultimate Choice for Emergency Water Supply: Integrated Dual Power Pump Unit

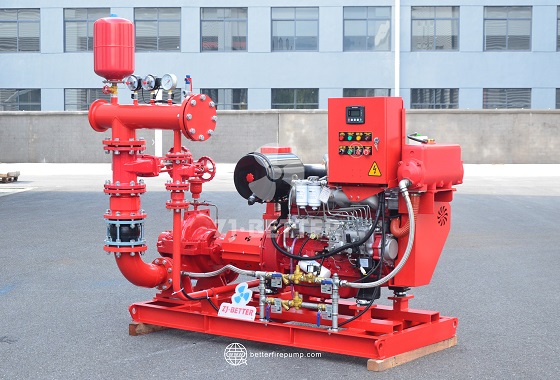

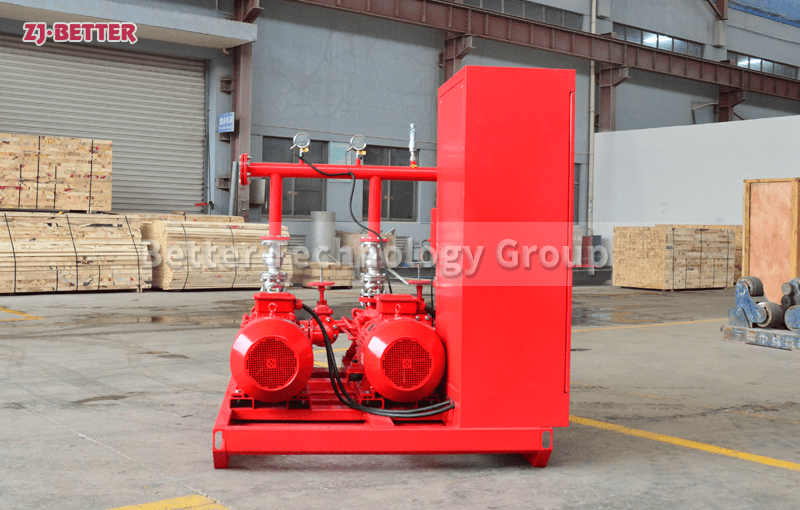

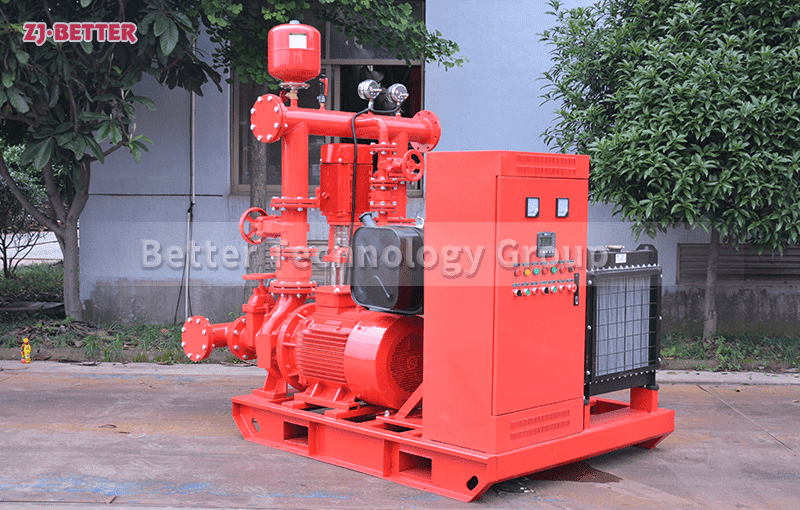

In emergency situations, uninterrupted water supply can be the deciding factor between safety and disaster. This integrated dual power fire pump unit combines a diesel engine and electric motor in one system, with an intelligent switch mechanism. When grid power is available, the electric motor operates the pump; when power fails, it automatically switches to diesel engine drive — ensuring continuous operation and stable water pressure.

Featuring a compact design and small footprint, this unit is easy to install and widely applicable in high-rise buildings, factories, warehouses, petrochemical sites, airports, and other critical areas requiring high-reliability fire protection.

Equipped with an advanced control panel, it supports remote monitoring and automatic start-stop functions, making safety smarter and more responsive.

Choosing this dual power pump unit means choosing reliability, efficiency, and unwavering protection for your emergency systems.

As a specialized manufacturer dedicated to fire pump system solutions, we focus on delivering high-efficiency, safe, and intelligent fire pump equipment to clients around the world. With a comprehensive system covering R&D, design, manufacturing, testing, and after-sales service, our product line includes electric fire pump sets, diesel engine pumps, jockey pumps, vertical turbine pumps, and control panels — widely applied in high-rise buildings, industrial zones, petrochemical plants, transportation hubs, and more.

Backed by advanced production facilities and rigorous quality control systems, we continuously drive innovation and product upgrades. Our products have passed multiple international certifications and are exported to Southeast Asia, the Middle East, Africa, South America, and beyond — earning the trust of global users.

Customer-oriented and safety-driven, we uphold the principle of “Quality First, Service Foremost,” providing customized fire protection solutions tailored to safeguard every critical moment.