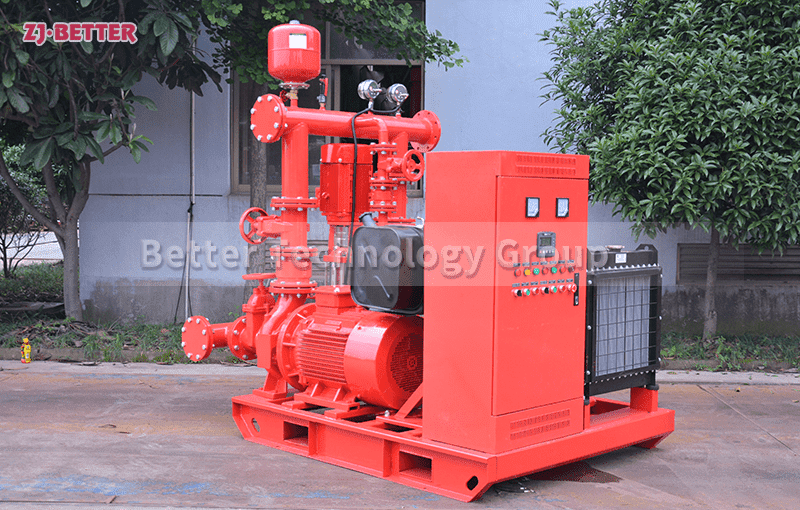

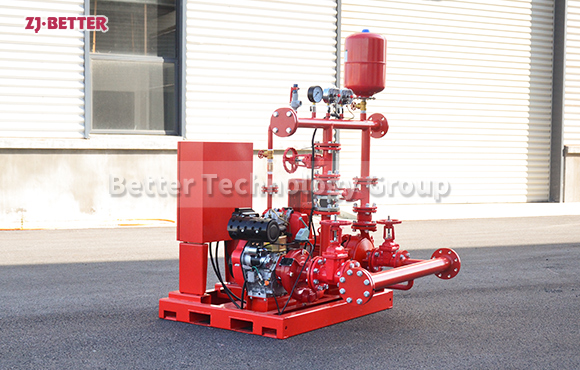

Application Value of High Efficiency End Suction Fire Pumps in Standard Fire Pump Rooms

High-performance fire pumps are designed for continuous and stable water supply to fire protection systems. They have advantages such as high head, large flow rate, stable operation, high temperature resistance and corrosion resistance. They are widely used in industrial plants, high-rise buildings, municipal fire protection and emergency water supply systems to meet the needs of various fire protection conditions and ensure reliable start-up and safe operation at critical moments.

High-efficiency end-suction fire pumps are among the most widely used fire water supply equipment in standard fire pump rooms. They occupy an important position in various building and industrial fire protection systems due to their mature structure, stable performance, convenient installation and maintenance, and reliable water output. This type of fire pump typically adopts a single-stage centrifugal structure and end-suction inlet/outlet arrangement, resulting in a compact overall structure and rational axis layout. It can achieve efficient fire water supply configuration within limited pump room space, making it very suitable for use in standard fire pump rooms constructed according to conventional fire protection codes. In terms of hydraulic design, high-efficiency end-suction fire pumps emphasize flow channel optimization and energy conversion efficiency. Through scientific impeller profile design and precise hydraulic matching, water flows more smoothly within the pump body, reducing hydraulic losses. While meeting the rated flow and head requirements of the fire protection system, it achieves stable and efficient energy output, thus providing a continuous and reliable water supply for fire hydrant systems, sprinkler systems, and other fire-fighting water equipment during a fire. These types of fire pumps typically use direct-drive or flexible coupling connections with the motor, resulting in high transmission efficiency and a simple structure. This effectively reduces mechanical losses and the probability of failure during operation, ensuring good reliability under both long-term standby and emergency operation conditions. Another major advantage of the end-suction structure is the intuitive layout of the inlet and outlet pipelines, facilitating connection with the fire protection network. The installation process is simple and standardized, effectively shortening the pump room construction cycle and reducing on-site installation difficulty. It also provides convenient conditions for later system upgrades and expansions. In terms of performance, high-efficiency end-suction fire pumps feature stable water output and minimal pressure fluctuations. After startup, they can quickly establish system pressure, enabling the fire protection network to reach its design operating conditions within a short time, meeting the stringent requirements of rapid response in fire protection systems. Their operating curve is stable, maintaining a good efficiency range under different operating conditions. This helps adapt to load fluctuations caused by changes in network conditions in practical applications, avoiding efficiency drops or operational instability due to operating condition deviations. To address the potential for prolonged continuous operation in fire protection systems, this type of fire pump has been carefully designed in terms of material selection and structural strength. The pump body is typically made of high-strength, corrosion-resistant materials, and key internal components possess excellent wear resistance and impact resistance, enabling stable operation under high load conditions for extended periods without significant performance degradation. The shaft seal structure and bearing system are also optimized for fire protection conditions, ensuring reliable sealing, low operating vibration, and effectively reducing leakage risks and mechanical wear, thereby extending the overall service life of the equipment. The high-efficiency end-suction fire pump’s value in standard fire pump rooms is also reflected in its excellent system compatibility. It can work collaboratively with pressure-stabilizing pumps, standby pumps, and automatic control systems to form a complete fire water supply solution. Each pump performs its specific function during different operational phases, such as daily standby, pressure maintenance, and fire emergency response, ensuring a clear overall operational logic and high reliability for the fire protection system. This type of fire pump is highly adaptable to electrical control systems and can be used with various control cabinets and monitoring systems to achieve functions such as automatic start-up, operational status monitoring, and fault alarms, making fire pump room management more standardized and efficient. For standard fire pump rooms, high-efficiency end-suction fire pumps also offer significant advantages in maintenance. Their mature structure facilitates easy disassembly and assembly, and routine inspections and repairs are simple, requiring no complex specialized tools. This reduces subsequent operation and maintenance costs and ensures the equipment remains in good technical condition throughout its long-term service life. Due to their stable performance and wide applicability, these fire pumps are suitable not only for fire protection systems in residential, office, and commercial complexes, but also for industrial plants, warehousing and logistics centers, and public infrastructure—places with high fire safety requirements. In summary, high-efficiency end-suction fire pumps, with their mature and reliable structural design, excellent and stable hydraulic performance, and good installation and maintenance characteristics, demonstrate outstanding application value in standard fire pump rooms. They are a crucial foundational piece of equipment for building safe, efficient, and reliable fire water supply systems, and are of great significance for improving the emergency response capability and operational stability of the overall fire protection system.

-2.jpg)