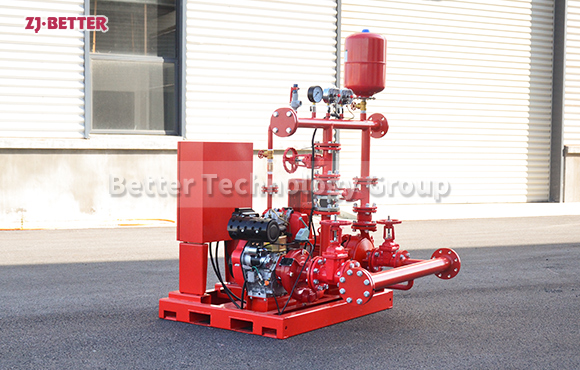

Industrial Small Fire Circulation Pump for Building and Emergency Firefighting Systems

Industrial-grade small fire circulating pumps are designed specifically for building and emergency fire extinguishing systems. They feature high head, large flow rate, stable operation, energy efficiency, and compact structure. They are suitable for sprinkler systems, fire hydrant systems, and industrial fire protection networks, providing a continuous and reliable fire water supply solution.

This industrial-grade mini fire circulating pump is suitable for building and emergency fire extinguishing systems. It is a high-performance water supply device specifically developed for the needs of modern building fire water supply and industrial emergency fire extinguishing. The overall structure adopts a horizontal, compact design with direct drive between the motor and pump body, reducing energy loss and mechanical deviation caused by intermediate connection links. This results in smoother and more efficient operation, providing continuous and reliable water pressure support in fire pipeline systems of high-rise buildings, commercial complexes, underground parking lots, industrial plants, municipal public facilities, and warehousing and logistics centers. The core of this product utilizes a high-efficiency hydraulic model design, with a precisely dynamically balanced impeller and optimized flow channel streamline structure, significantly reducing hydraulic losses and improving flow output efficiency. It achieves energy-saving operation while ensuring high head output, making it particularly suitable for various fire-fighting conditions such as automatic sprinkler systems, fire hydrant systems, foam extinguishing systems, and pressure stabilization and water supply systems. The pump body is made of high-strength cast iron or ductile iron, and key internal flow components can be made of stainless steel depending on the operating conditions. This provides excellent corrosion resistance and wear resistance, maintaining stable performance under long-term high-frequency start-stop environments and extending the overall service life of the equipment. The mechanical seal system features a high-temperature and wear-resistant design, maintaining excellent sealing performance even under high-pressure conditions, reducing the risk of leakage, and ensuring the fire protection system can start quickly and operate continuously in critical moments. The motor is equipped with a high-efficiency, energy-saving, fully enclosed, air-cooled motor with excellent heat dissipation and insulation levels, adaptable to continuous operation, meeting the 24-hour standby requirements of the fire protection system, and achieving instantaneous and efficient response in the event of a fire, ensuring the water pressure quickly reaches the design value. The entire unit operates with low noise and vibration; the base uses a thickened steel structure and is equipped with a shock-absorbing design, effectively reducing the impact on the building structure during operation, making it particularly suitable for commercial buildings and residential facilities with high noise control requirements. This industrial-grade small fire circulating pump was designed with ease of installation and space adaptability in mind, featuring a compact structure, small footprint, and standardized inlet and outlet flanges for easy and quick connection to existing fire protection pipe networks. System upgrades can be completed without complex modifications, greatly shortening the construction cycle and reducing installation costs. In terms of maintenance, the pump body adopts a modular structure design, allowing for easy disassembly and assembly of key components, enabling maintenance personnel to quickly inspect or replace parts, reducing downtime and improving the overall system reliability. The product undergoes rigorous testing in both hydraulic performance and pressure testing to ensure stable output under rated flow, rated head, and various load conditions. Its performance curves cover a wide range, and parameters can be matched and customized to meet the design standards of fire protection systems of different scales. Addressing the complex and variable nature of industrial environments, this fire circulating pump possesses excellent environmental resistance, enabling long-term stable operation in humid, high-temperature, dusty, or confined spaces. It also supports multiple control methods, allowing integration with fire control cabinets, pressure sensors, and automated monitoring systems for remote monitoring and automatic start/stop control, enhancing the overall intelligence of the fire protection system. The product also excels in energy-saving design. By optimizing the impeller diameter and speed, it maintains low power consumption during routine inspections and pressure stabilization, rapidly increasing to rated output in emergency fire situations, achieving a balance between energy saving and performance. This fire pump is widely applicable to high-rise office buildings, hospitals, schools, shopping malls, hotels, data centers, and industrial manufacturing plants, ensuring fire safety while meeting the dual requirements of modern buildings for equipment reliability and economy. Its structural stability and material strength have undergone extensive durability testing, maintaining excellent performance curves even under continuous operation and frequent start-stop conditions. It is less prone to bearing overheating or mechanical misalignment, ensuring long-term safe system operation. The pump shaft is made of high-strength alloy steel and precision-machined, combined with high-quality bearing components, effectively reducing friction loss, improving transmission efficiency, and extending the overall service life of the equipment. To adapt to the voltage and frequency standards of different countries and regions, motor parameters can be flexibly configured to meet the diverse needs of the global market and facilitate export integration for engineering projects. The product design fully considers the reliability requirements of fire protection systems, ensuring rapid start-up after power restoration, while also supporting backup power system access to guarantee continuous water supply in emergencies. For the high-pressure water supply needs of emergency fire extinguishing systems, this circulating pump maintains a stable flow rate even at high head output, preventing water hammer due to pressure fluctuations and effectively protecting the pipeline system. The entire machine is coated with a corrosion-resistant industrial-grade coating, providing excellent rust and oxidation resistance, maintaining stable performance even in humid environments or long-term outdoor installations. The product can be configured as a single pump or multiple pumps in parallel to form a fire pump system, depending on the project scale. This allows for graded flow control and redundant design, improving system safety. Through scientific hydraulic design and rigorous manufacturing process control, this industrial-grade small fire circulating pump ensures fire safety while also offering advantages such as energy efficiency, structural stability, convenient maintenance, and flexible installation. It provides a reliable fire water supply solution for modern buildings and industrial sites. Its stable performance output and durable structural design enable it to maintain excellent performance under various complex fire conditions, laying a solid foundation for users to build safer, more reliable, and more efficient fire water systems. It is an indispensable core device in building fire protection systems and emergency fire extinguishing systems.