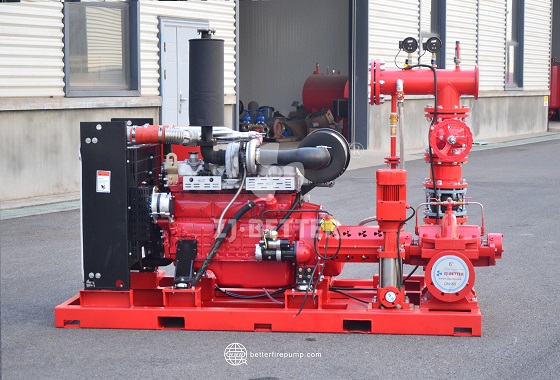

Weatherproof Enclosed Diesel Fire Pump Set for Municipal and Industrial Firefighting

The weather-resistant box-type diesel fire pump unit is designed for municipal and industrial fire protection systems. It features independent diesel power, box-type protective structure, and stable and efficient water supply performance. It can start up quickly and run continuously in power outages and harsh environments, meeting the needs of high head and large flow fire water. It is suitable for outdoor deployment, industrial parks, and emergency fire protection scenarios.

The application analysis of weather-resistant box-type diesel fire pump units in municipal and industrial fire protection mainly focuses on their long-term stable water supply capability in complex environments, high-reliability power system, structural protection performance, and high adaptability to various fire protection scenarios. These devices typically use a diesel engine as an independent power source, enabling them to quickly start and continuously output stable flow and pressure even in the event of municipal pipeline pressure loss, power outages, or extreme emergencies. This ensures that the fire protection system is not limited by external energy conditions at critical moments, fundamentally improving the overall fire safety level. The box-type structural design is one of the core advantages of this type of fire pump unit. An integrated protective shell integrates the diesel engine, fire pump, control system, cooling system, and fuel system into a single structural unit, effectively isolating the internal critical components from the effects of rain, sand, dust, high humidity, and temperature changes. This allows the equipment to be deployed outdoors, in factory open spaces, in areas with limited pump room conditions, or at temporary emergency fire stations without performance degradation. The weather-resistant casing is typically made of high-strength steel plate or composite materials, with a surface treated for corrosion resistance, rust prevention, and weather resistance coatings. It can withstand high and low temperatures, coastal high-salt spray, desert sandstorms, and industrial pollution environments, extending the overall service life of the equipment and reducing the frequency of maintenance and operating costs. In terms of performance, this type of diesel fire pump unit is equipped with a dedicated fire pump. The pump’s hydraulic design is optimized for the high-lift, high-flow, and rapid-response requirements of fire protection systems, enabling it to establish stable water pressure quickly and maintain stable flow output under long-term continuous operation. This meets the diverse water needs of municipal fire hydrant systems, industrial sprinkler systems, foam extinguishing systems, and fire protection systems in large tank farms. The diesel engine is typically designed for low speed and high torque, providing excellent load response and fuel economy. It maintains reliable operation even under high load and long-term operation, preventing water supply interruptions due to insufficient power. In terms of control systems, weather-resistant box-type diesel fire pump units are generally equipped with intelligent control cabinets, featuring automatic start, manual start, remote linkage, and multiple protection functions. When the system detects a drop in pipeline pressure or receives a fire signal, it can automatically start the equipment in a very short time, achieving rapid response under unattended conditions. It also has multiple safety protection mechanisms, including overspeed, low oil pressure, high water temperature, and battery undervoltage protection, ensuring timely alarm or shutdown in abnormal operating conditions to prevent equipment damage. Low-noise design is also a key performance advantage for this type of unit in municipal and industrial applications. By installing sound-absorbing materials inside the enclosure, optimizing the air intake and exhaust structure, and using high-efficiency silencers, the operating noise of the diesel engine is effectively reduced, making the equipment more suitable for operation near residential areas, municipal roads, or industrial parks with high environmental noise requirements, meeting the environmental protection and noise control management requirements of various regions. The cooling system has also been specifically optimized for the box-type structure, using a combination of forced air cooling or water cooling to ensure that the engine and pump unit still have sufficient heat dissipation capacity in a closed environment, preventing excessive temperature from affecting continuous operating performance. For municipal fire protection systems, these weather-resistant box-type diesel fire pump units can be used as main pumps, standby pumps, or emergency pumps. They are particularly suitable for remote areas, the end of pipeline networks, areas with insufficient water pressure, and temporary fire protection facility construction projects. They can be quickly deployed and put into use, improving the overall coverage and reliability of municipal fire protection systems. In the field of industrial fire protection, their application scope is even wider, covering various scenarios such as petrochemicals, power energy, warehousing and logistics, manufacturing plants, ports and docks, and large public facilities. Facing high-risk, high-fire-load industrial environments, these devices provide solid protection for fire protection systems with their independent power, stable output, and weather-resistant protection advantages. The overall skid-mounted structure design makes the equipment more convenient during transportation, installation, and commissioning. It can be quickly positioned and connected to pipelines according to project needs, shortening the construction cycle, reducing installation costs, and also facilitating later maintenance and overall replacement. In summary, weather-resistant box-type diesel fire pump units, with their excellent environmental adaptability, reliable power performance, stable water supply performance, intelligent control, and low-noise design, demonstrate extremely high application value in municipal and industrial fire protection systems. They are an indispensable and important water supply equipment in modern fire protection engineering, capable of providing continuous and reliable fire water support for life and property safety at critical moments.