Automatic Fire Booster Water Supply Equipment – Enhancing Emergency System Reliability

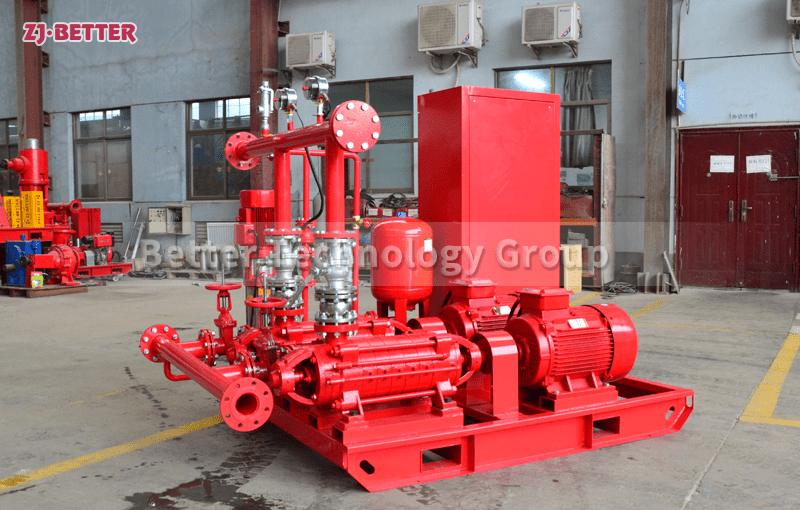

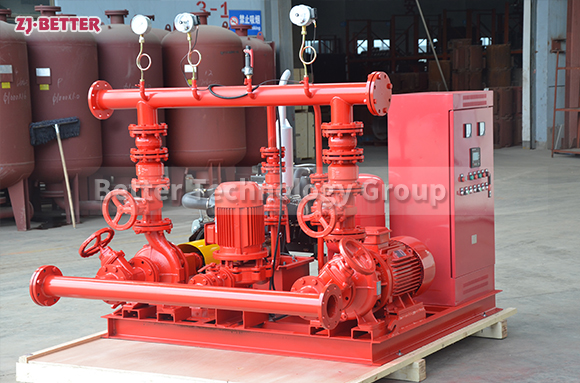

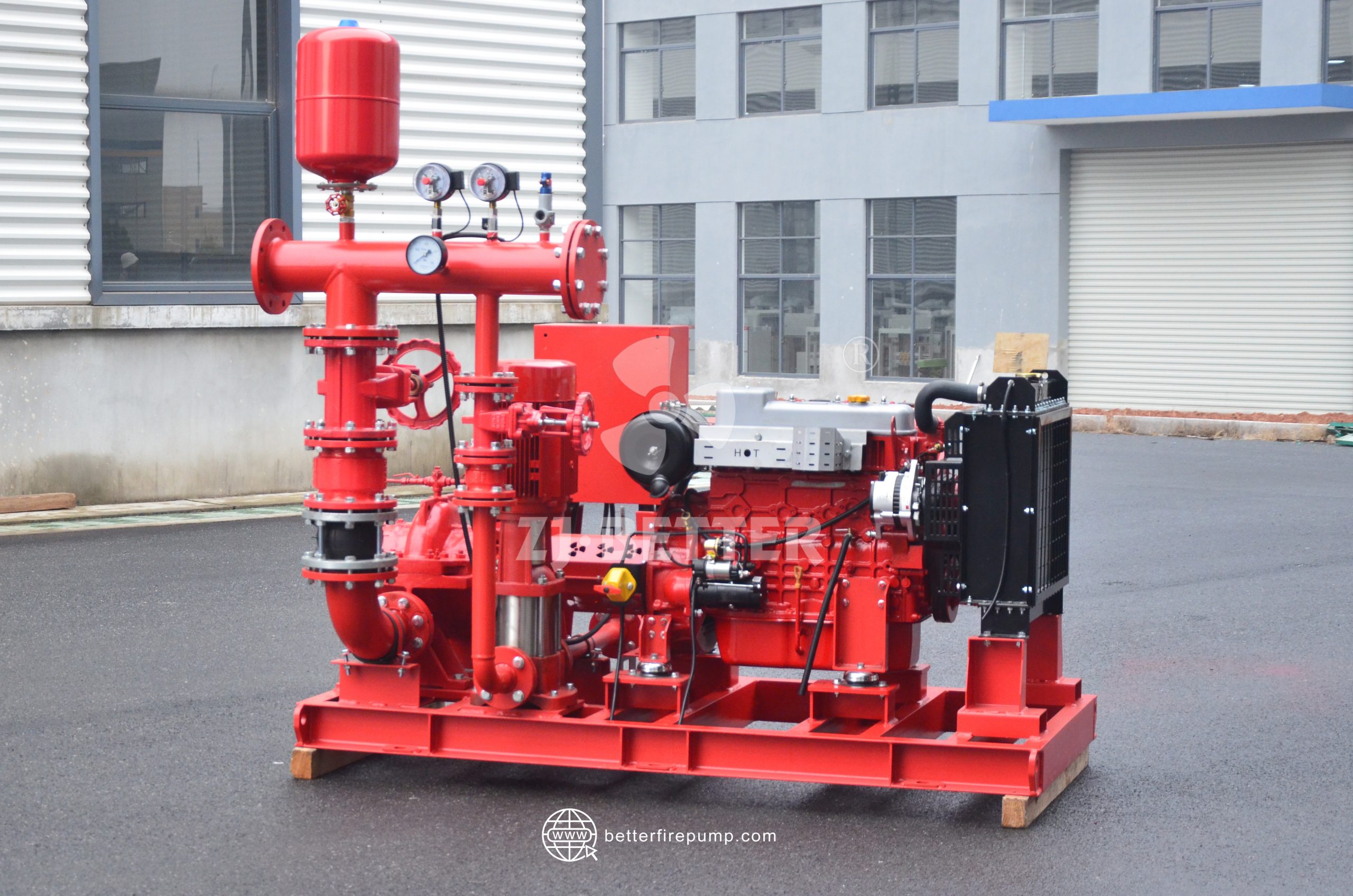

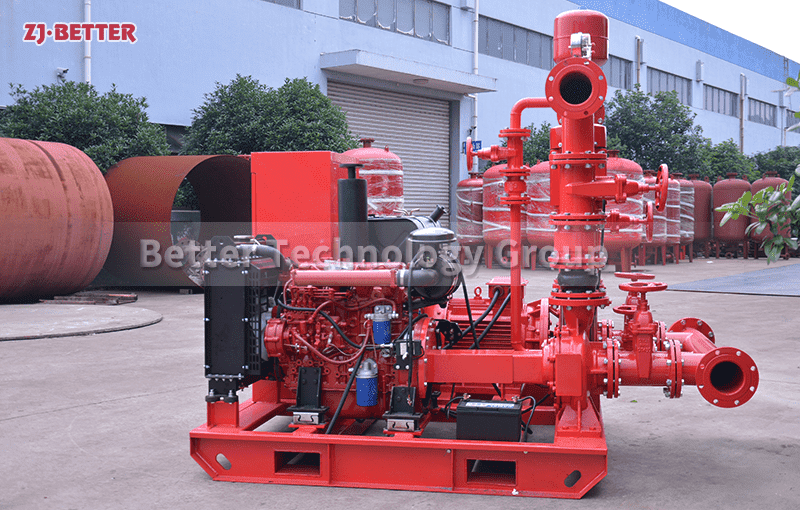

Automated fire-fighting booster water supply equipment offers the advantages of intelligent control, stability, efficiency, energy conservation, and environmental protection. It is suitable for high-rise buildings, factories, warehouses, and complexes, ensuring continuous and stable water pressure, improving fire-fighting efficiency, and system reliability.

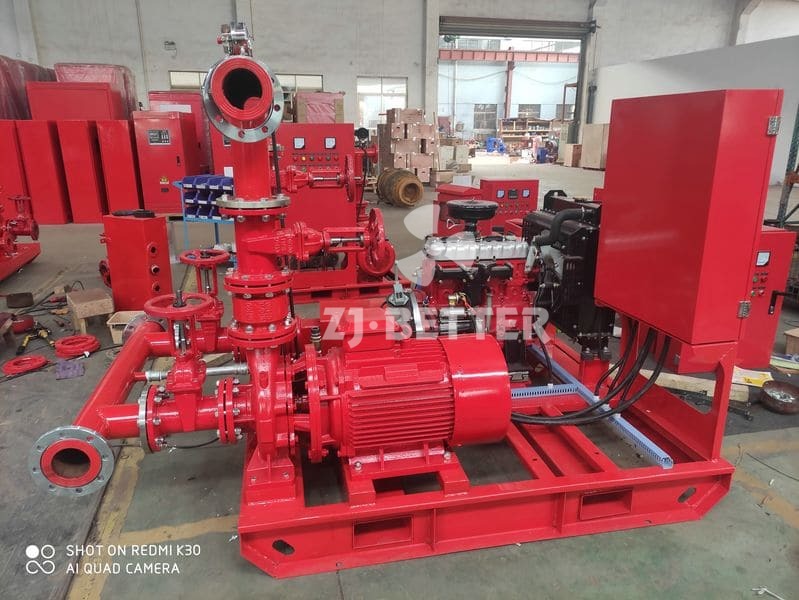

Automated fire-fighting booster water supply equipment is a highly integrated, reliable, and intelligent fire-fighting water supply solution. It is widely used in modern buildings, industrial plants, warehouses, logistics, public facilities, and other fields to meet the stringent requirements for stable water pressure and sufficient water volume in fire emergencies. This equipment utilizes a dual or multi-pump parallel design, combined with advanced automatic control systems, to achieve rapid response in any situation, ensuring a continuous and stable supply of fire water, making it a crucial component for enhancing fire safety levels. The greatest advantage of this type of equipment lies in its automated operation. Intelligent monitoring modules and sensors monitor pipe network pressure in real time. When pressure drops below a set value, the system immediately activates a pump to replenish pressure, ensuring sufficient pressure in the pipe network at all times. Once a fire breaks out, a stable water flow is available to the sprinkler system or fire hydrants, improving firefighting efficiency and preventing the spread of fire due to insufficient water supply. Automated control not only reduces manual intervention and the risk of human error, but also enables the entire system to remain on standby 24 hours a day. This high degree of automation significantly enhances the reliability and safety of firefighting systems. The equipment is particularly outstanding in terms of performance. It adopts an efficient and energy-saving motor and pump body structure, with smooth operation, low noise and low energy consumption, which meets the requirements of modern energy conservation and environmental protection. The pump body material is usually made of high-quality wear-resistant and corrosion-resistant materials. It can maintain stable performance during long-term high-intensity operation and is not affected by complex environments. It is especially suitable for fire protection needs in high-rise buildings and large industrial sites. In the pump body design, the flow channel optimization and impeller structure improvement have greatly improved the hydraulic efficiency of the water pump. The water outlet flow is stable and the head is sufficient to meet the hydraulic parameter requirements in different application scenarios. The system can realize single pump operation, double pump alternating operation or multiple pumps at the same time according to actual needs, thereby achieving the unity of energy saving and high efficiency, avoiding excessive wear caused by long-term operation of a single pump, and also extending the service life of the overall equipment. Automated fire-fighting booster water supply equipment also has advanced advantages in terms of intelligence. It is equipped with a PLC control system or a microcomputer control system, which can realize automatic switching of multiple working modes, including automatic start and stop, timed start and stop, manual operation, etc. At the same time, it has a complete alarm function. For example, abnormal conditions such as overload, phase loss, undervoltage, overpressure, and water leakage will trigger an alarm and shut down the equipment in time for protection, effectively preventing equipment damage and safety accidents. Some equipment also supports remote monitoring and remote control. Managers can use the control terminal or mobile terminal to grasp the equipment operation status in real time, adjust parameters and perform maintenance operations, which greatly improves management efficiency and safety. This remote and intelligent function is especially suitable for large complexes and unmanned places, providing strong support for modern smart fire protection. The rationality of the structural design is also one of its performance advantages. The overall layout of the equipment is compact, the footprint is small, and the installation is easy. It usually adopts a modular design, which is convenient for transportation, assembly and maintenance. The pipeline interface design is standardized and can be quickly connected to the existing pipeline system, greatly shortening the construction period and reducing installation costs. In terms of maintenance, the equipment is equipped with a variety of easy-to-disassemble structures to facilitate daily inspection and maintenance. At the same time, the internal key components have good interchangeability, making spare parts replacement more efficient and convenient, and reducing the subsequent operation and maintenance costs. This humanized design not only improves the user experience, but also ensures the long-term reliable operation of the equipment. Automated fire-fighting booster water supply equipment shows great flexibility in application scenarios. It can not only be applied to traditional building fire-fighting water supply systems, but also meet various needs such as industrial cooling, production water supply, and domestic pressure-stabilized water supply. The multi-purpose feature of one machine makes its investment value higher. Especially in high-rise buildings, due to the large resistance of the pipeline network and high water pressure requirements, ordinary water supply equipment is often difficult to meet the requirements. The automated fire-fighting booster water supply equipment can achieve stable high-lift water supply through intelligent adjustment to ensure that the top floor can also obtain reliable water pressure. In large factories and storage places, the equipment uses dual pumps in parallel or multiple pumps to ensure sufficient water supply during peak periods and achieve energy-saving operation during off-peak periods, which not only ensures fire safety but also reduces overall energy consumption. In addition, the automated fire-fighting booster water supply equipment also has significant energy-saving and environmental protection performance. The equipment uses high-efficiency motors and optimized hydraulic components, with a high energy efficiency ratio. The power consumption during operation is greatly reduced. At the same time, the system can intelligently adjust the operating status of the pump according to real-time water demand to avoid energy waste. This intelligent energy-saving mode not only reduces the cost of use, but also conforms to the development direction of green buildings and energy conservation and environmental protection. In long-term operation, the energy consumption and maintenance costs saved make the overall return on investment of the equipment extremely high, and the economic benefits are significant. In summary, the automated fire-fighting booster water supply equipment has become an indispensable and important fire-fighting equipment in modern construction and industry with its advantages of automated control, stable and efficient performance, intelligent management, reasonable and compact structural design, and energy conservation and environmental protection. It not only improves the safety and reliability of the fire protection system, but also reduces the operation and maintenance costs, meets the needs of different environments and application scenarios, and is an ideal choice for protecting life and property and improving the overall level of fire protection. The application and promotion of this equipment is not only the inevitable result of technological development, but also an irreplaceable and important part of the fire safety system in modern society.