Application and Advantages of Diesel Engine Jockey Pump Sets in Fire Protection Systems

Diesel engine jockey pump unit ensures stable fire system pressure with independent power supply, reliable operation during power outages, smart control, energy efficiency, and flexible installation, widely used in high-rise buildings, industrial parks, warehouses, and critical facilities for enhanced fire safety.

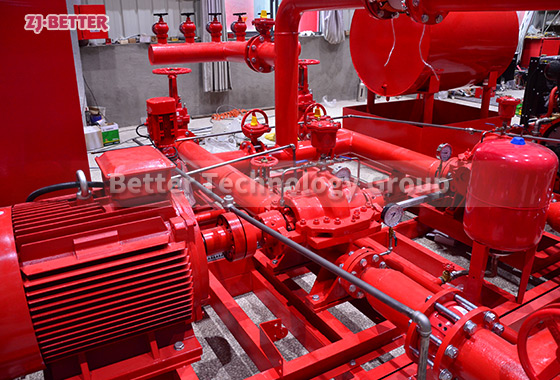

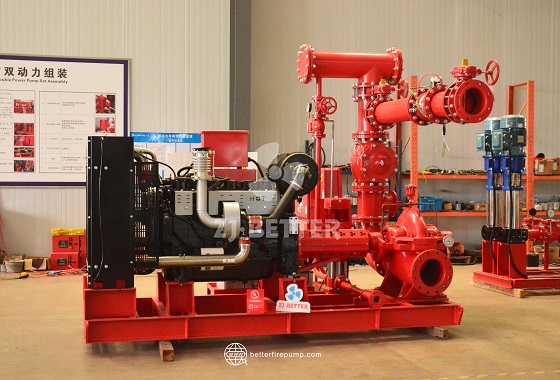

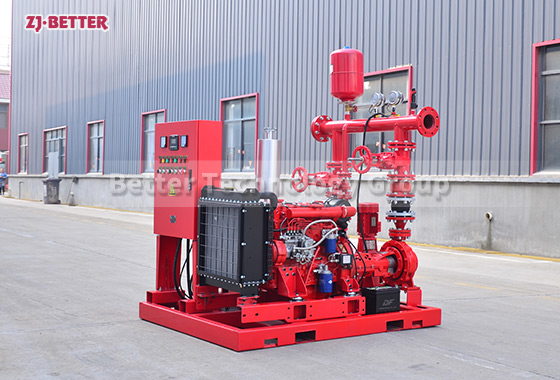

The application and advantages of diesel engine pressure-stabilizing pump sets in fire protection systems have always been the focus of the industry. With the continuous improvement of fire safety requirements in modern buildings, this type of equipment has gradually become the core configuration for ensuring system pressure with its efficient and stable performance, and plays an irreplaceable role in the entire fire water supply system. This article will comprehensively introduce the structural characteristics, performance advantages, application scenarios and significance of diesel engine pressure-stabilizing pump sets to the overall operation of fire protection systems from multiple perspectives. The diesel engine pressure-stabilizing pump set is a complete set of equipment specially used to maintain the stability of the fire protection system pipeline network pressure. It usually consists of a diesel engine, a pressure-stabilizing pump, a control cabinet, a piping system, a sensor device and corresponding auxiliary components. The basic principle of the equipment is to monitor the pipeline network pressure in real time. When the pressure drops to the set value, the pressure-stabilizing pump is automatically started to replenish water and pressurize, thereby ensuring that the system is in a state that can be put into fire extinguishing at any time. The diesel engine as the power core not only ensures normal operation in the absence of power, but also provides greater reliability for the system. Compared to electric pressure-stabilizing pumps, diesel-powered pressure-stabilizing pumps offer significant advantages. Their independent power source enables them to maintain effective fire protection system operation even during power outages or unstable electricity. This is particularly important in high-rise buildings, industrial parks, large storage facilities, and remote areas, where power outages are common. Relying on electric pumps can result in insufficient pressure or even a complete water supply failure. Diesel-powered systems, however, ensure system stability. Diesel-powered pressure-stabilizing pumps exhibit high efficiency and intelligent performance. Their automatic monitoring and control system collects real-time pipeline pressure data and quickly activates the pumps to increase pressure when needed. They also feature automatic switching and protection features, providing alarms and protective measures in the event of a fault or anomaly, preventing damage to the system due to overload or abnormal operation. This not only enhances safety but also extends the life of the equipment. Furthermore, these equipment are designed with energy conservation and low maintenance costs in mind. High-efficiency diesel engines offer low fuel consumption and excellent operating efficiency. Optimized hydraulic structures and pump materials ensure a longer service life and reduce the need for frequent maintenance. Diesel engine pressure-stabilizing pump sets also offer flexible installation and adaptability. The entire unit can be designed as either fixed or mobile according to user needs. Skid-mounted structures, in particular, with a base and integrated piping, facilitate quick installation and commissioning, saving on-site construction time. Their compact and rational layout also reduces floor space, making them ideal for space-constrained machine rooms or temporary fire stations. Furthermore, to meet the needs of diverse application environments, diesel engine pressure-stabilizing pump sets typically support a variety of configurations and customization options. For example, varying flow rates and lifts can be selected based on building height and pipeline network size, and high-temperature, corrosion-resistant, or low-noise designs can be selected based on environmental conditions. This flexibility significantly enhances the equipment’s adaptability. This pump unit has a wide range of applications. In high-rise buildings, the pressure-stabilizing pump unit can ensure that sufficient pressure is always maintained at the top of the pipe network, ensuring normal water flow from sprinklers and fire hydrants. In large industrial plants, it can cope with complex working conditions and multi-point water supply needs. In high-risk industries such as petrochemicals, steel, and electricity, diesel engine pressure-stabilizing pump units provide continuous fire protection for critical facilities. In addition, in airports, ports, and large logistics and storage bases, this type of equipment has become the preferred option due to its independent and reliable operation capabilities. In the overall operation of the fire protection system, the significance of the diesel engine pressure-stabilizing pump unit lies not only in maintaining the pressure of the pipe network, but also in its role as a guarantee link before the main pump is put into operation. When the system pressure drops slightly, the pressure-stabilizing pump unit will compensate, avoiding frequent starting and stopping of the main pump, extending the life of the main pump, and ensuring that the pipe network has emergency water supply capabilities at all times. It can be said that it is both a protective umbrella for the system and an enhancer of operating efficiency. From a safety perspective, the independent nature of diesel engine pressure-stabilizing pump units makes them a last resort in critical situations. Modern designs also incorporate multiple protection features, such as low-fuel alarms, high-water-temperature shutdowns, and abnormal oil pressure protection. These ensure safer and more reliable operation, ensuring stable output even under extreme conditions, thereby enhancing the fire protection system’s overall resilience. From a maintenance and user-friendliness perspective, these pump units feature user-friendly interfaces, intelligent control cabinets, and displays that clearly display operating parameters and status, allowing users to intuitively understand the equipment. Some models also support remote monitoring and data transmission, facilitating centralized management and troubleshooting, significantly improving operational efficiency and management. The future development of diesel engine pressure-stabilizing pump units is also worth watching. With the application of intelligent and IoT technologies, pump units will achieve closer integration with fire control centers. Remote real-time monitoring and big data analysis will not only detect potential problems promptly but also enable preventive maintenance, further improving reliability and operational efficiency. Environmental protection and energy conservation are also key developments. In the future, diesel engine pressure-stabilizing pump units will continue to be optimized in terms of combustion efficiency, emissions reduction, and noise control, moving towards a green and efficient approach. In summary, diesel engine pressure-stabilizing pump groups have become an indispensable and important equipment in modern fire protection systems due to their advantages of independent power, high efficiency and stability, intelligent control and flexible adaptability. They play a key role in ensuring the safety of buildings and facilities. Whether it is high-rise buildings, industrial plants or important infrastructure, they all need to rely on this equipment to provide reliable fire water supply guarantees. With the continuous advancement of technology, this type of equipment will surely show stronger application value and broader market prospects in more fields.