Compact Diesel Fire Pump System: A Highly Efficient Stand-Alone Firefighting Solution for Emergency Use

High-performance compact diesel fire pump system offering fast start-up, independent operation, strong water pressure and reliable emergency firefighting support for multiple applications.

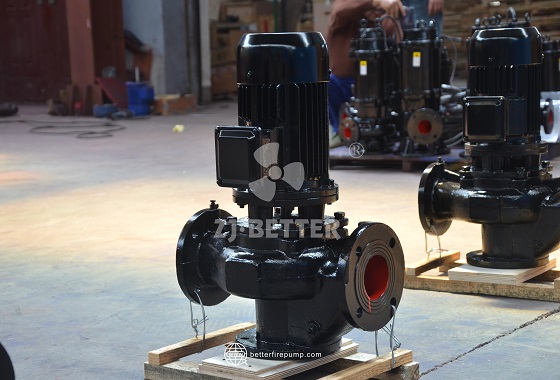

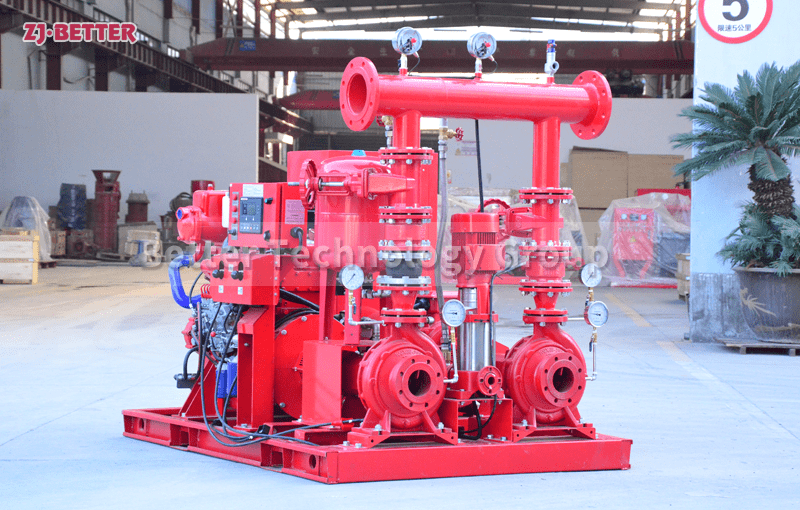

Small diesel engine fire pump systems, as indispensable independent water supply power equipment in modern fire protection engineering, are widely used in building fire protection systems, industrial fire protection systems, municipal fire protection projects, and field emergency fire fighting scenarios due to their outstanding advantages such as no need for external power supply, rapid start-up, compact structure, and wide applicability. With the increasing demands for fire safety in various locations, small diesel engine fire pump systems demonstrate higher professional value in terms of initial fire response time, independent operation capability, water supply stability, mobility, and environmental adaptability. This product uses a high-efficiency diesel engine as its power source. Through optimized combustion and exhaust systems, the equipment can reach rated speed and output strong power in a short time. Even in the absence of mains power, power outages, remote areas, or emergency situations, it can still operate stably, ensuring a continuous and reliable water pressure for the fire protection system. The entire system is designed according to the principles of high efficiency, reliability, and ease of maintenance. From the engine to the pump body, from the control system to the base structure, everything has been rigorously optimized to adapt to long-term continuous operation and complex environmental conditions. The compact structure of the small diesel engine fire pump system is one of its main advantages. Through a highly integrated design, the engine, water pump, fuel tank, control cabinet, monitoring instruments, and auxiliary systems are tightly integrated onto a robust chassis. This design not only minimizes the equipment’s footprint but also facilitates transportation, installation, and relocation, making it particularly suitable for firefighting operations with limited space and high mobility requirements. In emergencies, the equipment can be moved directly to a designated location by trailer, vehicle, or manually for rapid deployment in firefighting operations. It is especially suitable for outdoor temporary firefighting, field firefighting, isolated buildings, construction areas, and other areas where mains power is unavailable. Furthermore, the integrated design effectively reduces piping connection points, thereby lowering the risk of leaks and improving the system’s long-term stability. Regarding start-up performance, the small diesel engine fire pump system employs automatic or manual multi-mode start-up. The automatic start-up system monitors pressure switches, water pressure changes, or fire system signals. Once a pressure drop or fire command is detected, the equipment automatically enters operational status within seconds, significantly shortening response time. Rapid start-up capability is crucial for controlling fires in their initial stages, as every second of delay can allow the fire to spread. Meanwhile, the system also supports manual start-up. Even if the automatic system fails to trigger under special circumstances, operators can still quickly start the unit via the control panel, ensuring redundant reliability. To ensure long-term operational stability, the equipment uses a high-safety-standard diesel engine, characterized by low fuel consumption, low failure rate, and strong durability. The engine is precisely tuned to maintain high efficiency in different altitudes, temperature ranges, and humidity environments, and can operate stably in environments ranging from -15℃ to 50℃. It can even be configured with preheating devices and cold-weather adaptation systems to achieve broader environmental adaptability. The engine’s lubrication, cooling, and fuel systems all use industrial-grade configurations, enabling the equipment to operate continuously under high loads for extended periods, suitable for emergency backup water supply needs in large-scale fire protection projects. Regarding pump performance, the fire pumps equipped in the small diesel engine fire pump system feature high head, large flow rate, and strong cavitation resistance. The pump body is made of high-strength materials, possessing excellent pressure resistance and corrosion resistance, and can stably output high-pressure water flow, ensuring continuous and effective pressure in the fire protection network. The impeller is hydraulically optimized to maintain high-efficiency hydraulic performance during high-speed rotation, ensuring stable operation even when pumping water containing trace impurities. The system can provide different flow and pressure combinations to meet the various fire protection conditions, including sprinkler systems, fire hydrant systems, and foam extinguishing systems. The control system, a core component, employs an intelligent design concept, enhancing reliability in operation management and safety monitoring. The control cabinet integrates functions such as oil pressure monitoring, water temperature monitoring, speed monitoring, battery voltage monitoring, automatic alarm system, automatic protection system, and operation timing. When the equipment detects low oil pressure, high water temperature, overspeed, or other abnormal conditions, it immediately issues an alarm and executes automatic protection measures according to settings to prevent engine damage and extend equipment lifespan. For locations requiring remote monitoring, a remote communication module can be configured to connect to the fire control room, allowing managers to monitor equipment status at any time and improve the overall reliability of the fire protection system. In terms of maintenance, the small diesel engine fire pump system features a rational structural design, with key components located in easily accessible positions, making daily maintenance, inspection, and troubleshooting easier. The unit adopts an open layout, facilitating comprehensive inspection of the oil, water, and electrical systems by operators. Routine maintenance includes changing the engine oil, cleaning the filter element, inspecting belts, testing instruments, and testing automatic functions. Maintenance cycles are long, and maintenance costs are low, making it suitable for long-term use as backup power equipment for fire fighting. Regarding spare parts supply, the standardized configuration makes replacement of parts more convenient and quick, reducing downtime and improving overall system availability. The small diesel engine fire pump system also boasts high applicability and can be customized to different usage scenarios. For example, it can be equipped with a larger fuel tank to meet long-term operating needs; add chassis wheels for field operations; add an insulated enclosure for cold regions; add a soundproof enclosure for noise-sensitive areas; add a backup starting battery to extend independent operating capacity; and add an auxiliary pump to meet more complex fire fighting system requirements. Whether for fixed installations inside buildings, outdoor fire pump stations, fire protection facilities in industrial plants, warehousing and logistics centers, oil tank areas, docks, mines, substations, or emergency fire fighting and rescue in the field, the small diesel engine fire pump system can provide safe, reliable, and rapid fire fighting power support. In summary, small diesel engine fire pump systems, with their comprehensive advantages such as independent operation capability, rapid start-up performance, strong power output, stable and continuous water supply, intelligent control, compact structure, and easy maintenance, have become an irreplaceable and crucial piece of equipment in modern fire protection systems. In locations with unstable mains power, high fire risk, or where mobile and flexible firefighting capabilities are required, they are not only core equipment for emergency backup water supply but also vital fire protection barriers to ensure the safety of personnel and property. With the continuous development of fire protection technology, this efficient and independent fire-fighting power system will continue to play a key role, providing highly reliable fire protection for various locations worldwide.