Starting process of diesel engine fire pump

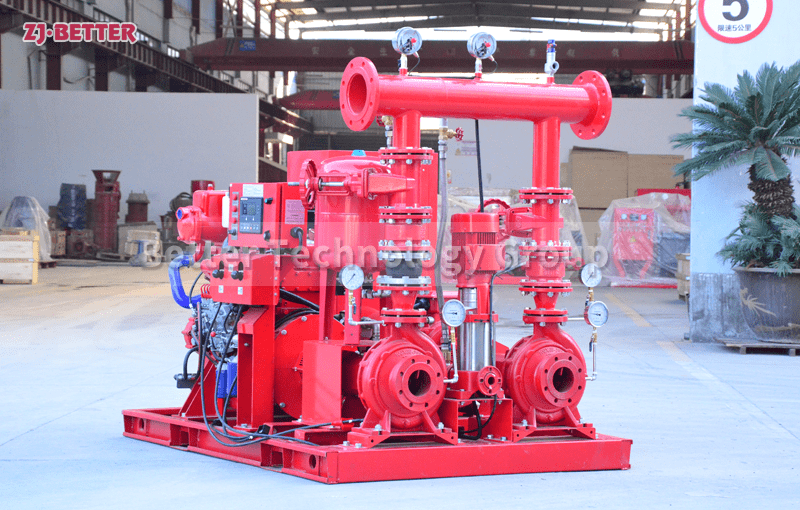

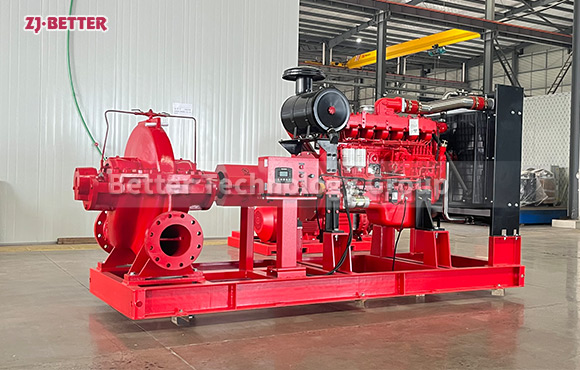

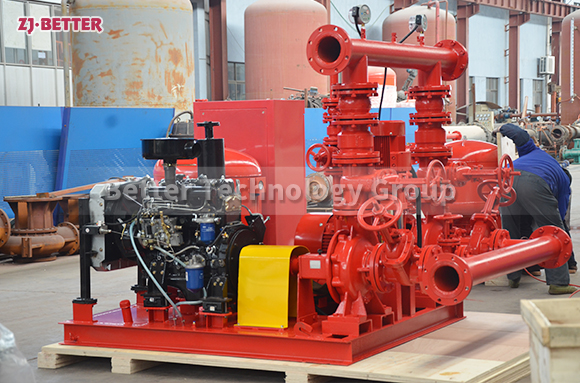

Diesel engine fire pumps are mainly used for emergency fire fighting on ships. At the same time, it is also suitable for industrial and mining enterprises, port terminals, warehouses and freight yards and other places. Diesel engine fire pump, as a fixed fire extinguishing equipment, has been widely used in fire diversion, especially in emergencies such as no power supply or abnormal power supply, it can also be equipped with other diesel engines as power engines according to the needs of users.

Diesel engine fire pumps used for firefighting purposes are relatively strict. Generally, two sets of batteries are equipped with double backup to ensure the normal operation of diesel engine fire pumps. When the controller can run normally, it will send a signal to the starter motor. There are two types of starter motors, one is manual and the other is automatic. If the starter motor can operate normally, then a signal is fed back to the controller, and then the controller sends a signal to the speed control board, and the speed control board controls the throttle driver to supply oil to the oil pump. After entering the oil, the air is compressed and the diesel is burned to do work, so that the diesel engine starts to do work to start. The connection between the diesel engine and the water pump is somewhat different from the traditional one, which uses a clutch. Why use a clutch, because when the water pump is empty, it needs a lot of force to drive it, and the function of the clutch is to share the two, start the diesel engine first, and then the diesel engine runs, and the water pump is sucked in through the clutch. Drive the operation of the water pump. But the problem is that using the clutch is very inconvenient for maintenance, etc., and the clutch does not have an oil lubrication system, so the damage is relatively serious.