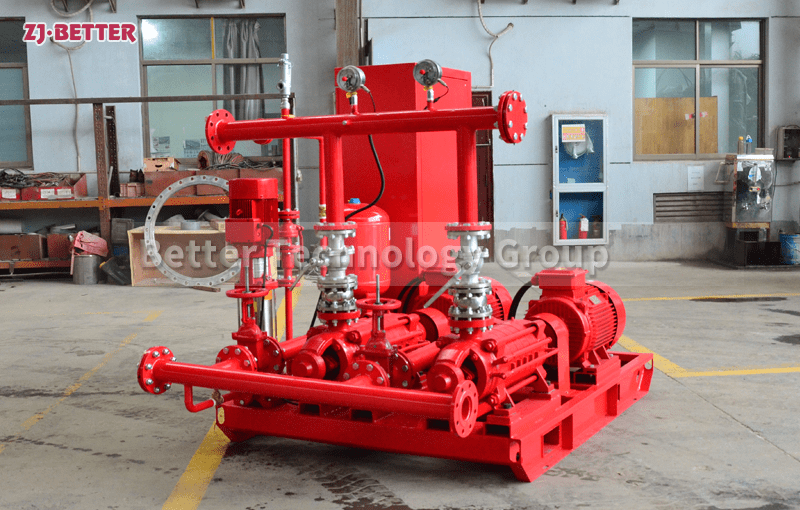

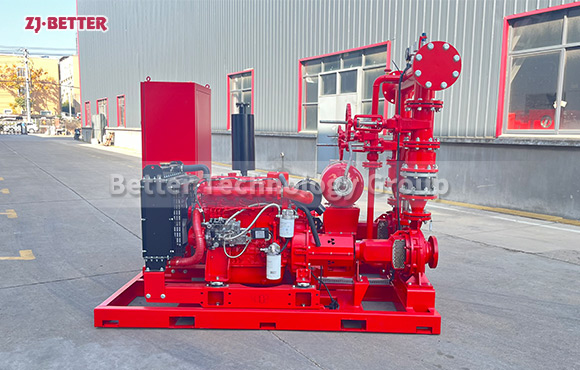

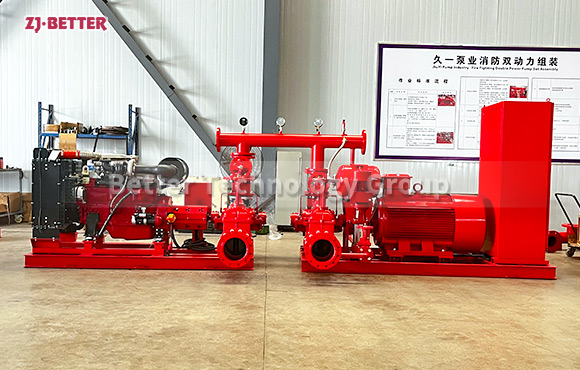

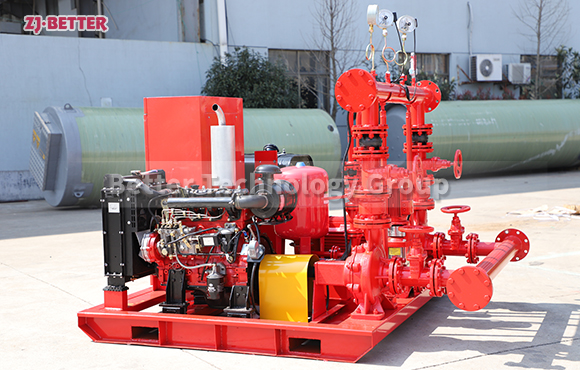

Made in China standard complete set of fire pump set equipment

Application fields of fire pump set:

Industrial fields: various petroleum, petrochemical, chemical, oil fields, management bureaus, oil depots, oil terminals, oil refineries, offshore platforms, etc., national grain depots, thermal power plants, steel mills, shipyards, paper mills, etc.;

Commercial fields: five-star hotels, hospitals, schools, supermarkets, office buildings, large commercial complexes, highway tunnels, subway stations, railway stations, airports, fire engineering companies.

Fire pumps are an important part of a building’s fire protection system, especially in high-rise buildings. Fire pumps are critical in distributing water through sprinkler systems in situations where water pressure from water mains and fire equipment cannot be reached. Even in lower buildings, fire pumps are key to controlling fires.

We can provide diesel-driven fire pumps, electric fire pumps, jockey pumps and complete fire pump sets that comply with NFPA20 standards or UL/FM certification according to the user’s choice.