Fire Pump Control Systems: Ensuring Efficiency and Reliability in Firefighting Operations

Discover the advanced features of ZJ-Better Fire Pump Control Systems. Learn how our intelligent, automated systems ensure efficient firefighting, with smart diagnostics, remote monitoring, and energy-saving capabilities for enhanced reliability and performance in emergency response.

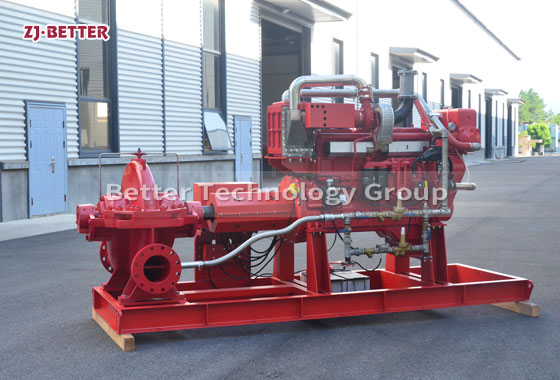

In modern fire protection systems, fire pumps play a critical role. They are not merely simple water pumps but the core equipment of the entire fire suppression system. Fire pumps provide powerful water flow and high-pressure water sources, enabling firefighters to extinguish fires promptly and minimize damage. With technological advancements, traditional fire pumps have gradually been replaced by more intelligent and efficient fire pump control systems. The ZJ-Better fire pump control system is one of the leading innovative products on the market, combining advanced automation and intelligent technology to significantly enhance the efficiency and reliability of firefighting operations. This article will provide a detailed overview of the advantages of the ZJ-Better fire pump control system, exploring how it enhances fire safety in practical applications and ensures the efficiency and reliability of firefighting operations.

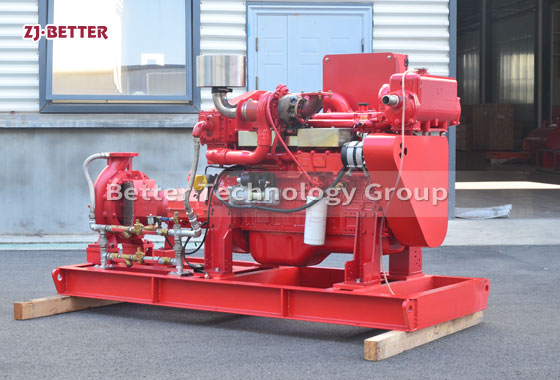

One of the core advantages of the ZJ-Better fire pump control system is its highly automated functionality. Traditional fire pump systems typically require manual intervention to start and adjust the pump’s operating status, while the ZJ-Better fire pump control system employs intelligent control technology to automatically adjust water flow, pressure, and pump operating modes based on real-time monitoring data. The system collects important data such as water flow, pressure, and pump body temperature in real time through sensors and monitoring devices installed on the fire pump, and transmits this information to the control system for analysis. When the system detects any abnormalities, it automatically adjusts the pump’s operating status to ensure the equipment operates at optimal performance, thereby preventing reduced firefighting efficiency caused by human operational errors or equipment failures.

Additionally, the ZJ-Better fire pump control system features intelligent fault diagnosis and self-repair capabilities. In the event of a fire, time is of the essence, making every second critical. Traditional fire pumps often require manual intervention for inspection and repair when malfunctions occur, which not only wastes valuable time but may also delay firefighting operations. The ZJ-Better fire pump control system, equipped with an intelligent fault diagnosis system, can detect any abnormalities in the equipment in real-time, including pump operation status, motor faults, and pipeline leaks, and provide detailed reports on the location and cause of the fault. The system can also perform self-repair to some extent, such as automatically adjusting water flow or restarting the equipment, ensuring it continues to operate and minimizing the impact of the fault.

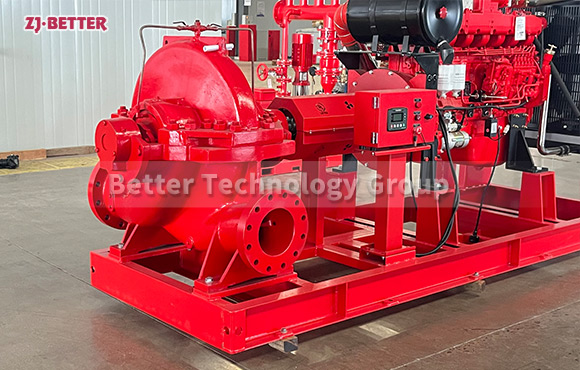

The ZJ-Better fire pump control system can also be networked with other fire protection equipment to form a highly integrated fire protection system. Modern buildings and industrial facilities have increasingly complex fire safety requirements, necessitating not only efficient fire pumps but also seamless integration with other systems such as fire alarm systems, sprinkler systems, and fire hydrant systems. The ZJ-Better fire pump control system supports seamless integration with these systems, enabling centralized management and coordination of the entire fire protection system through a single central control platform. In the event of a fire, the system can automatically determine the optimal firefighting strategy based on the actual fire situation, quickly adjust the operational status of various devices, and ensure that firefighting resources are optimally allocated and utilized. For example, when the system detects a fire in a specific area, it can automatically adjust the water flow of the fire pump to concentrate more water resources in that area and extinguish the fire through the sprinkler system or fire hydrants, ensuring that the fire is extinguished in the shortest possible time.

Another key advantage of the ZJ-Better fire pump control system is its remote monitoring and control functionality. In large buildings or industrial parks, fire pumps often require 24/7 operation and regular inspections and maintenance. To ensure fire pumps function properly at all times, the ZJ-Better system features remote monitoring, allowing users to view real-time parameters such as operational status, flow rate, and pressure via computers or mobile devices. Through the remote control platform, users can start, stop, or adjust settings at any time, eliminating the inconvenience associated with traditional manual inspections and operations. During a fire, the remote monitoring function also provides real-time data support to firefighters, helping them make more accurate decisions and improve firefighting efficiency.

In addition to its intelligent and automated functions, the ZJ-Better fire pump control system also boasts high reliability and stability. As the core equipment of a fire suppression system, the stability of fire pumps directly impacts the effectiveness of the entire firefighting operation. The ZJ-Better fire pump control system incorporates redundant backup technology in its design to ensure continuous operation even in the event of a malfunction. For example, the power supply section of the control system employs a dual power supply design, ensuring that the system can continue to operate normally even if one power supply fails. Additionally, the system’s control modules and sensors have undergone rigorous testing to ensure they can operate stably under extreme conditions. Whether in high temperatures, humidity, or vibration, the ZJ-Better fire pump control system can maintain efficient operation, providing reliable support for firefighting efforts.

The ZJ-Better fire pump control system also features a user-friendly interface with an excellent user experience. The system is equipped with an intuitive touchscreen display, allowing users to view pump operating status, adjust water flow, and check alarm information with simple operations. Additionally, the system supports multi-language switching, making it convenient for users from different regions and countries. The interface is simple and intuitive, enabling users to quickly get started without requiring extensive technical knowledge, significantly enhancing operational convenience.

The energy-saving performance of the ZJ-Better fire pump control system is another key highlight. As energy costs continue to rise, energy efficiency has become a critical consideration for many industrial and commercial facilities. The ZJ-Better fire pump control system intelligently regulates water flow and pressure to avoid the common issue of over-operation in traditional fire pump systems. When water flow demand is low, the system can automatically reduce water flow, thereby decreasing energy consumption. Through this intelligent regulation, the ZJ-Better fire pump control system not only improves firefighting efficiency but also effectively reduces energy waste and operational costs.

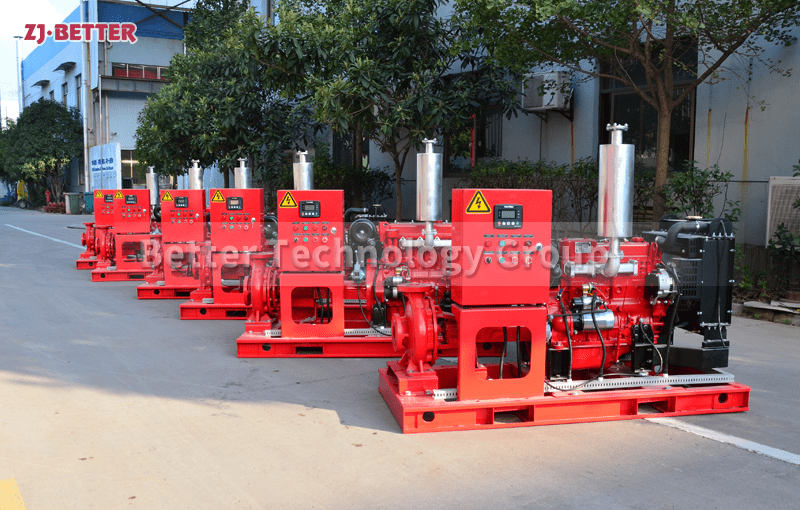

In the selection and configuration of fire pump systems, the ZJ-Better fire pump control system has become the preferred choice for many industrial and commercial facilities due to its efficient, intelligent, and reliable features. Whether in high-rise buildings, large factories, or high-risk industries such as petrochemicals, the ZJ-Better fire pump control system provides efficient and stable firefighting support, ensuring rapid response in the event of a fire and minimizing fire-related losses. Through advanced automation control technology, the ZJ-Better fire pump control system not only enhances the performance of fire pumps but also improves the collaborative capabilities of the entire fire protection system, providing businesses and users with safer and more efficient fire protection solutions.