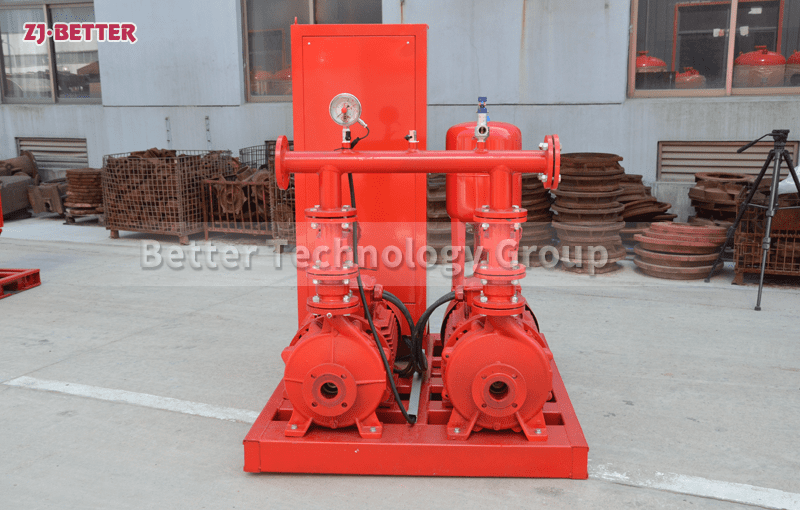

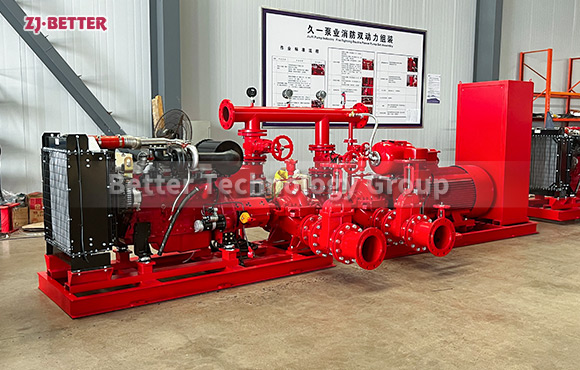

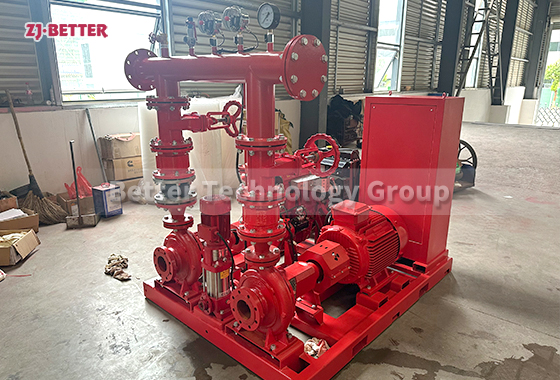

Integrated Piping Fire Pump Package Designed for Long-Term Fixed Fire Systems

Integrated fire pump units for fixed fire protection systems combine fire pumps, pipelines, valves, and control systems. They are compact, easy to install, start up quickly, and operate stably. They are suitable for high-rise buildings, industrial plants, and various long-term fire water supply scenarios, providing reliable and efficient fire water supply.

Integrated pipeline fire pump units are complete fire water supply systems designed for the long-term stable operation of fixed fire protection systems. The overall structure highly integrates the fire pump, drive unit, inlet and outlet main pipelines, valve components, pressure gauges, control system, and base. Through systematic design, it achieves efficient water delivery, rapid response, and reliable operation, making it suitable for applications with extremely high requirements for the continuity, safety, and stability of fire water supply. These fire pump units are designed from the outset with full consideration of the operational characteristics of fixed fire protection systems, emphasizing long-term standby and emergency start-up capabilities. In the event of a fire, they can quickly be put into operation and continuously output a stable water volume and pressure, providing reliable water source support for sprinkler systems, fire hydrant systems, and other fixed fire extinguishing facilities. The integrated pipeline structure effectively reduces on-site secondary piping and complex installation steps. The inlet and outlet pipelines, bypass pipes, test pipelines, and safety accessories have been fully assembled and sealed before leaving the factory. On-site installation only requires foundation fixing and interface connection before use, significantly reducing construction time and installation error risks, while also reducing system hazards caused by improper human operation. In terms of performance, this fire pump unit adopts a high-efficiency hydraulic model design. The impeller, pump casing, and flow channel have been optimized through calculations to ensure good efficiency and stable head output under both rated and off-peak conditions. This effectively avoids problems such as flow fluctuations, pressure instability, or cavitation during operation, thereby improving the reliability of the entire fire protection system. The drive system can be configured with a motor or other power sources according to project requirements, featuring rapid start-up, smooth operation, and long maintenance cycles, meeting the dual requirements of fixed fire protection systems for frequent self-checks and emergency starts. The unit is constructed with high-strength materials, and key pressure-bearing components possess excellent pressure resistance and impact resistance, capable of withstanding long-term static pressure and instantaneous pressure changes in the pipeline network, ensuring safety and reliability even under high-pressure fire water supply conditions. The sealing system adopts a mature and reliable structural design, effectively preventing leakage problems during long-term operation, reducing maintenance workload, and extending the overall service life of the unit. As a crucial component of the integrated pipeline fire pump unit, the control system features automatic start-up, manual control, operational status monitoring, and fault alarm functions. It can intelligently coordinate with system pressure changes, activating the fire pump immediately upon the occurrence of a fire or abnormal pipeline pressure to ensure uninterrupted water supply. Simultaneously, it remains on standby in non-emergency situations, reducing energy consumption and equipment wear. The pressure gauges, valves, and safety devices are rationally arranged for easy daily inspections and periodic maintenance, allowing management personnel to intuitively grasp the system’s operational status and improve operational efficiency. For long-term stationary fire protection systems, stability and durability are paramount. This type of fire pump unit is designed with continuous operation and long-term standby conditions in mind. Through reasonable heat dissipation design and structural layout, it ensures that the equipment maintains good performance under high load or long-term operation, avoiding performance degradation due to excessive temperature rise or component fatigue. The base uses an integral welded or steel structure, providing excellent rigidity and vibration damping performance, effectively reducing operating vibration and noise, protecting the pump body and pipelines, and extending the service life of bearings and seals. The integrated piping design not only enhances the overall aesthetics and standardization of the equipment, but more importantly, it plays a significant role in system safety. The unified piping layout reduces potential leak points, making the entire fire water supply system more compact and reliable. This fire pump unit is suitable for high-rise buildings, industrial plants, warehousing and logistics centers, data centers, commercial complexes, and various locations requiring fixed fire water supply systems. It can be flexibly configured according to the flow rate, head, and pressure requirements of different projects to meet diverse engineering needs. In long-term use, this equipment, with its reasonable structure, stable performance, and easy maintenance, effectively reduces the overall operating cost of the fire protection system while providing a continuous and reliable fire water supply for buildings and facilities. By highly integrating the core equipment with the piping system, the integrated piping fire pump unit ensures performance and safety while providing a more efficient and standardized fire protection solution for engineering projects, making it an indispensable and important component of modern fixed fire protection systems.