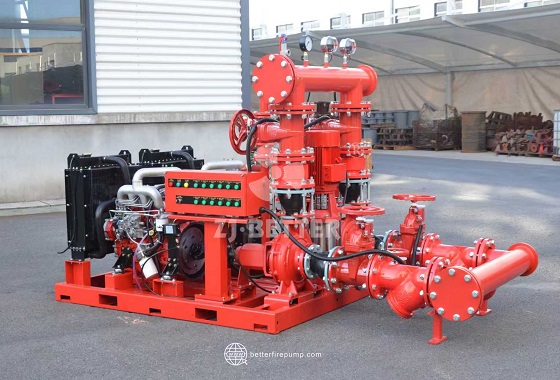

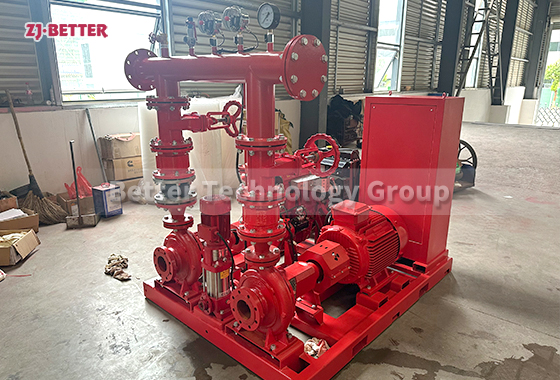

Diesel Fire Pump Set Engineered for Long-Time Continuous Operation

The diesel fire pump unit adopts a reliable diesel power and a high-efficiency centrifugal pump structure, and has the advantages of automatic start, long-term continuous operation, stable flow and head output. It is suitable for fire water supply systems in industrial plants, warehouses and logistics, petrochemical plants and areas without mains power, ensuring continuous, safe and reliable water supply in fire conditions.

This diesel fire pump unit is designed with the core objective of meeting long-term continuous operation requirements. It is specifically developed for high-intensity fire water supply scenarios. The overall structure fully considers engine stability, pump durability, cooling and lubrication system reliability, and continuous output capacity under complex on-site conditions. It is suitable for applications with extremely high fire safety requirements, such as industrial plants, large warehousing and logistics centers, petrochemical plants, ports, power facilities, high-rise buildings, and remote areas without mains power. The unit uses a diesel engine as its power source. Compared to electric fire pumps, it can quickly start and operate stably even in situations where mains power is interrupted, the power supply system is damaged in the early stages of a fire, or there is no stable power source in remote areas. This ensures uninterrupted fire water supply, buying valuable time for firefighting and personnel evacuation. The engine selection is based on a low-speed, high-torque output design, possessing excellent load adaptability. Under long-term full-load operation, the speed is stable, vibration is low, and heat attenuation is minimal, effectively avoiding flow and head instability caused by power fluctuations, fundamentally improving the reliability of the entire fire protection system. The unit is equipped with a high-efficiency cooling system. Through a large-capacity radiator, optimized air duct structure, and forced air cooling design, it ensures the engine maintains a reasonable operating temperature even in high-temperature environments or under prolonged continuous operation, preventing performance degradation or mechanical damage caused by overheating. The cooling system also features a compact layout with ample maintenance space, facilitating routine inspection and maintenance. The lubrication system employs a high-efficiency oil circulation design, ensuring sufficient lubrication of key moving parts. Even under continuous operation, this effectively reduces wear, extends engine life, and lowers overall maintenance costs. The fire pump section typically uses a single-stage or multi-stage centrifugal pump structure. The pump body is made of high-strength cast iron or corrosion-resistant metal materials, possessing excellent pressure resistance and wear resistance. It can operate stably for extended periods under high head and high flow conditions. The impeller undergoes precise dynamic balancing, effectively reducing operating noise and vibration, ensuring the unit remains stable during continuous operation. The shaft seal structure uses a reliable combination of mechanical seals or packing seals, providing excellent sealing performance and effectively preventing media leakage. It is suitable for conveying clean water and media with slight impurities, meeting the stringent safety and stability standards of fire protection systems. The entire unit adopts an integrated base structure, centrally mounting the engine, fire pump, coupling, control system, and auxiliary devices on a high-strength steel base. This compact structure and reasonable center of gravity not only improve the convenience of transportation and installation but also enhance the overall rigidity of the equipment, reducing the risk of structural fatigue during long-term operation. The coupling uses a high-strength, elastic connection method, effectively absorbing minor deviations and vibrations between the engine and pump shafts, reducing shaft wear, and further improving the reliability of continuous operation. Regarding the control system, the unit is equipped with a dedicated diesel fire pump control cabinet, featuring multiple operating modes including automatic start, manual start, and emergency start. It can be linked with fire alarm systems or pressure control devices. When pipeline pressure drops or a fire signal is triggered, the unit can start and operate in a very short time, ensuring timely and reliable water supply. The control system monitors the engine’s operating status in real time, including key parameters such as speed, oil pressure, water temperature, and battery voltage. In case of any abnormality, the system will promptly issue an alarm, helping maintenance personnel quickly diagnose the problem and prevent the equipment from continuing to operate in an unsafe condition, thus ensuring safety during long-term operation. The electric start system utilizes a high-capacity battery and a reliable charging device, ensuring sufficient starting energy even during prolonged standby. It can start smoothly even in low-temperature or high-humidity environments, meeting the stringent requirements of fire-fighting equipment for high start-up success rates. The fuel system design emphasizes stable fuel supply and filtration, effectively preventing impurities from entering the engine through a multi-stage filtration system. This ensures complete fuel combustion and stable power output. A large-capacity fuel tank or external fuel system allows for long-term continuous operation, reducing the operational risks associated with frequent refueling. This is particularly suitable for applications with prolonged fire durations or requiring repeated water supply. The diesel fire pump unit’s structural design fully considers on-site maintenance needs. Key components are rationally arranged, daily inspection points are clearly defined, and maintenance access is ample, facilitating quick maintenance, repairs, and troubleshooting, effectively reducing maintenance difficulty and downtime. The entire unit surface is treated with an anti-corrosion coating, providing excellent weather resistance and rust prevention. It can be used long-term in outdoor or semi-open environments, adapting to complex conditions such as high humidity, dust, or large temperature differences, further expanding its application range. With its stable power output, reliable pumping performance, comprehensive cooling and lubrication system, and mature automatic control and protection design, this diesel fire pump unit can maintain a high-efficiency, safe, and stable working state under long-term continuous operation conditions. It is an indispensable core water supply equipment in various fire protection projects, providing a solid guarantee for the continuous and reliable operation of the fire protection system.