Advanced Technology and Reliability Analysis of Diesel Fire Pumps

Explore the advanced technology and reliability of diesel fire pumps in this detailed article. Learn how these pumps ensure safety, provide efficient firefighting solutions, and offer long-lasting performance in demanding environments. Discover how technological innovations enhance operational efficiency, reduce energy consumption, and minimize environmental impact for superior fire protection.

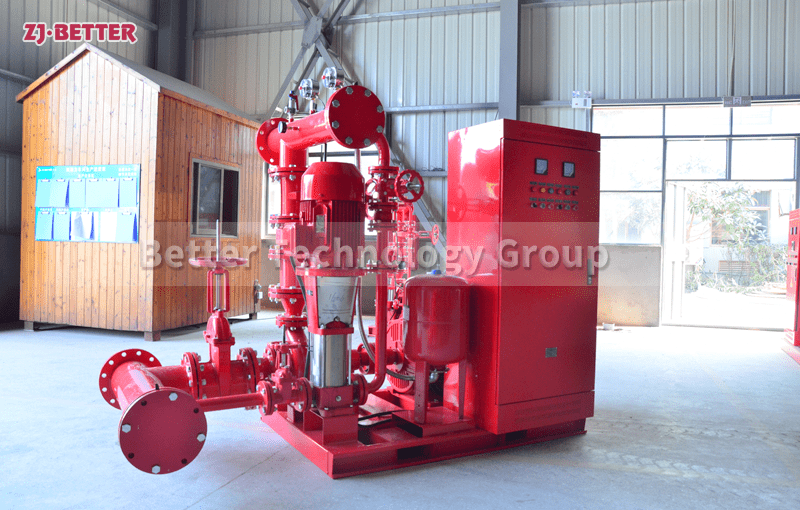

As a vital part of the emergency fire extinguishing system, the diesel fire pump is responsible for providing sufficient water pressure and flow to the fire site, ensuring the safety of personnel and effectively extinguishing the fire. With the continuous innovation of technology, the diesel fire pump is also constantly improving its performance and reliability, becoming an indispensable part of more industrial, commercial and residential buildings. This article will conduct an in-depth analysis of the advanced technology and reliability of diesel fire pumps, explore its role in fire emergency response and how to improve its operating efficiency and safety through technological innovation.

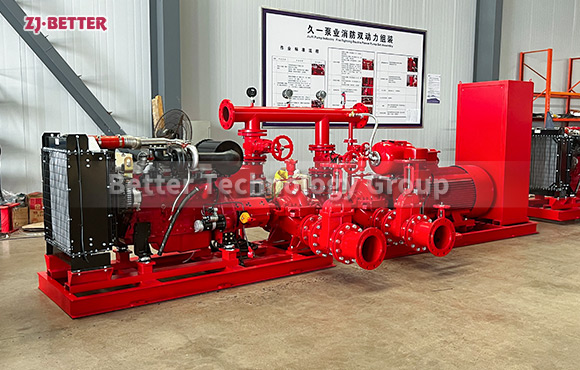

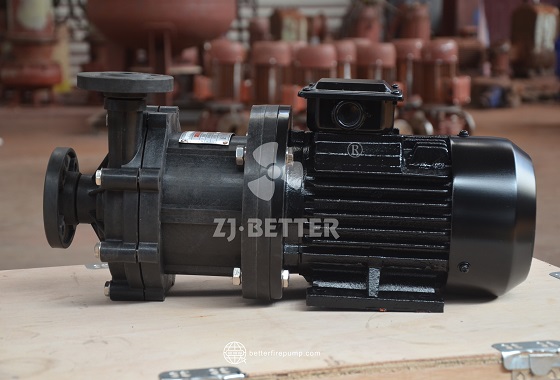

Modern diesel fire pumps use advanced design concepts and engineering technologies to ensure that they can start quickly and reliably when a fire occurs. The diesel-driven power system enables the fire pump to work without an external power supply, which is particularly suitable for emergency situations such as power outages or power outages. In addition, the diesel fire pump is also extremely durable and can withstand extreme working conditions to ensure long-term efficient and stable operation.

The selection of diesel engines is one of the cores of diesel fire pump performance. Advanced engine technology can provide stable power output in various environments, especially in high temperature or extremely cold environmental conditions, the diesel engine can maintain reliable starting performance and ensure uninterrupted operation of the system. This efficient engine technology reduces energy consumption, improves fuel efficiency, and reduces environmental pollution.

In terms of reliability, modern diesel fire pumps use multiple protection mechanisms, such as temperature sensors, pressure sensors, and automatic shutdown protection systems. These features not only improve the reliability of the pump body under extreme conditions, but also effectively avoid system failures and equipment damage, extending the service life of the equipment. In addition, diesel fire pumps are also equipped with a remote monitoring system, so that users can view the operating status of the equipment in real time to ensure that it is always in the best working condition.

Another key technology of the diesel fire pump system is automatic control. Through a precise electronic control system, the diesel fire pump can automatically detect key indicators such as water flow and pressure, and automatically adjust the pump speed and pressure output according to real-time conditions. This highly automated design makes the fire pump easier to operate, reduces the error rate of human operation, and improves the stability of the overall system.

Diesel fire pumps also have the characteristics of rapid response. Whether it is the operation of firefighters on the scene or the automated response of the equipment, it can start and provide maximum water flow pressure in the shortest time. This high responsiveness can quickly extinguish the fire source in the early stages of the fire and reduce the losses caused by the fire.

The application scope of diesel fire pumps is also expanding. It is not limited to industrial, commercial and civil buildings. They are also widely used in special environments such as the oil and gas industry, chemical plants, ports, etc. Especially in places such as petrochemicals and natural gas processing, the stability and efficiency of diesel fire pumps have become key equipment to ensure the safe operation of facilities.

Although diesel fire pumps have so many advantages, their maintenance is also crucial. Regular inspection and maintenance can ensure the long-term stable operation of the equipment and reduce the occurrence of sudden failures. Common maintenance items include checking the fuel system, cleaning the filter, replacing the loss parts, etc. In addition, the oil pressure, coolant and engine battery of the diesel engine need to be regularly inspected to ensure that they are in the best condition.

In the future, the technology of diesel fire pumps will continue to develop. With the development of intelligence and Internet of Things technology, the management and maintenance of diesel fire pumps will be more intelligent and automated. Through big data analysis and remote control, the future diesel fire pump system will be able to automatically notify maintenance personnel when a failure occurs, shorten the maintenance time, and improve the availability and reliability of the system.

With the continuous improvement of environmental protection requirements, the emission standards of diesel fire pumps are also constantly improving. Modern diesel engines use low-emission technology to reduce exhaust emissions and meet more stringent environmental regulations. Through this technological advancement, diesel fire pumps can reduce negative impacts on the environment while ensuring efficient performance.

In short, as an important facility to ensure life and property safety, diesel fire pumps have become an indispensable part of modern fire emergency systems with their reliability, advanced technology and efficient operation. With the continuous advancement of technology, diesel fire pumps will play a greater role in improving work efficiency, reducing energy consumption, and reducing environmental pollution, providing stronger support for fire protection around the world.

.jpg)