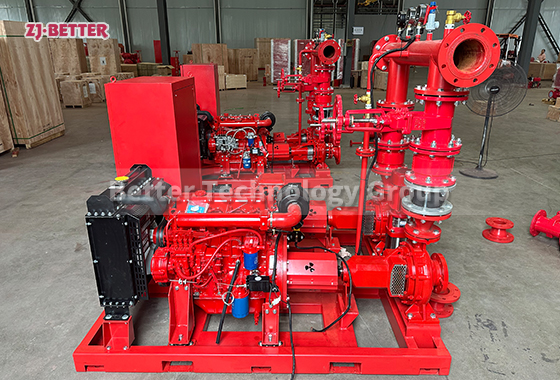

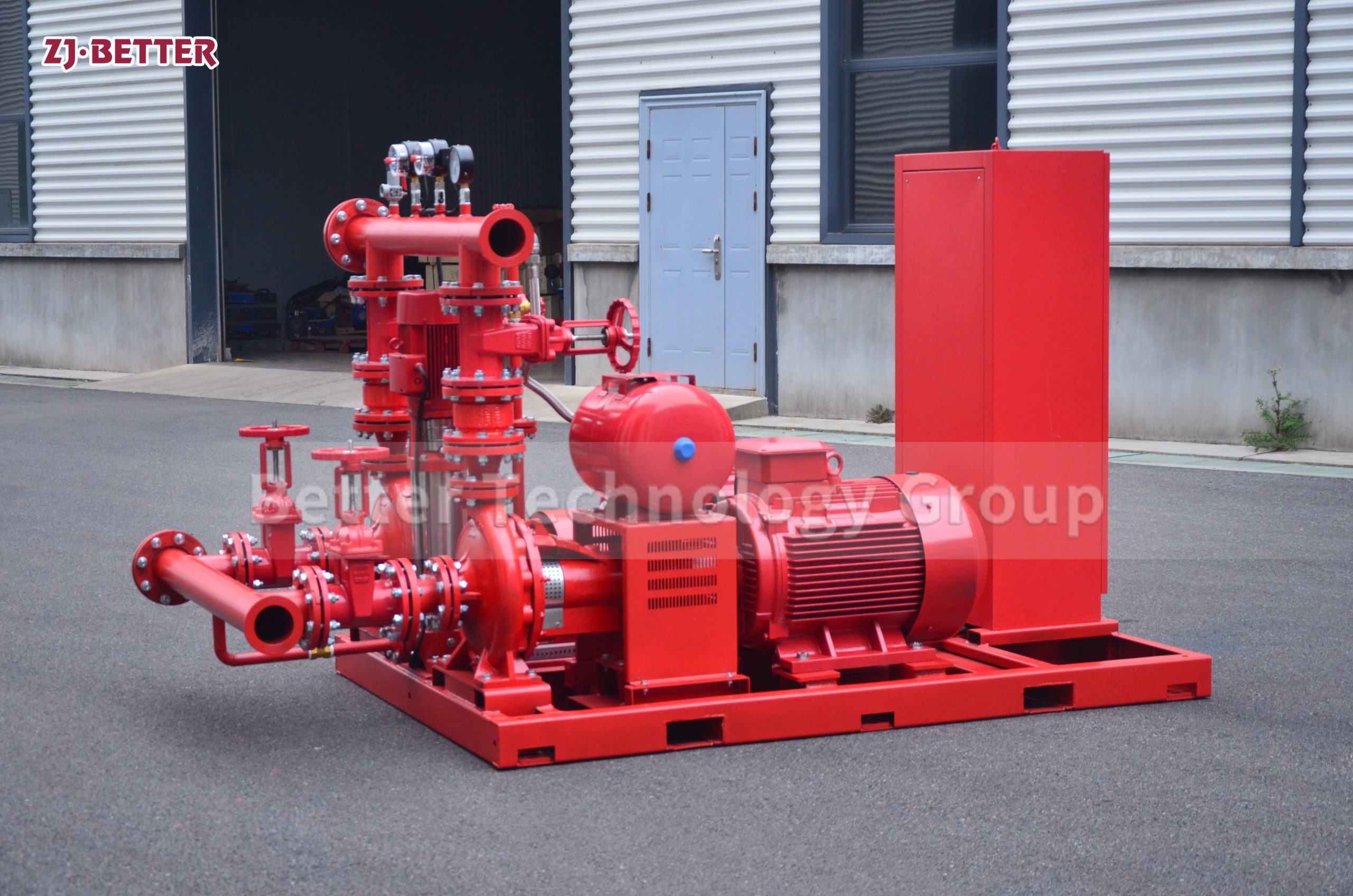

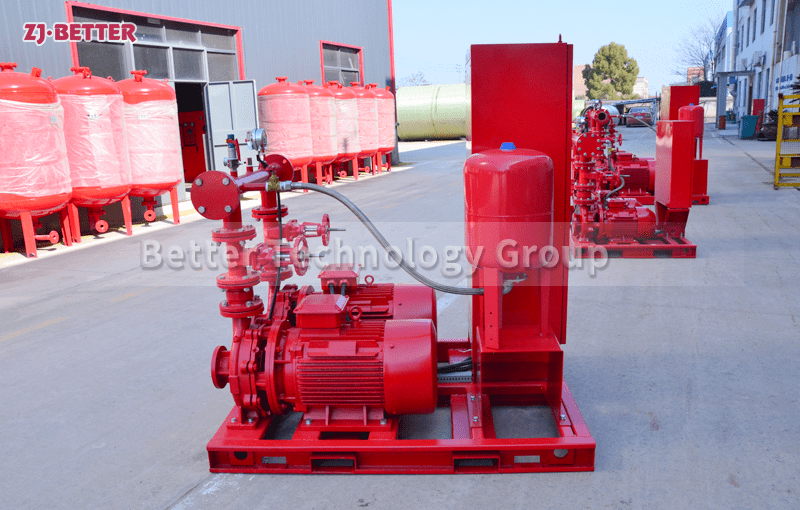

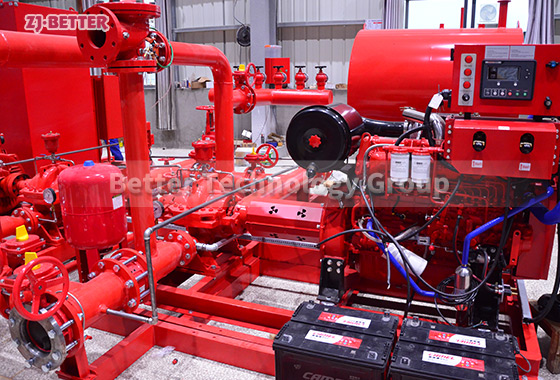

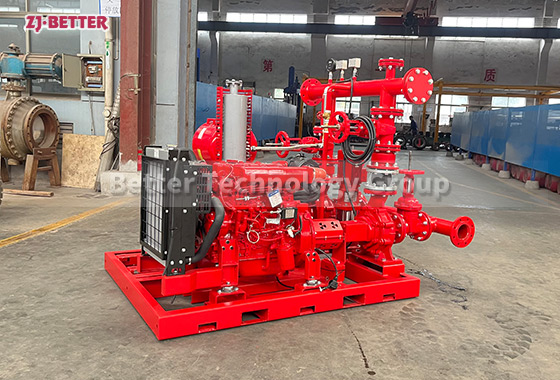

High-Quality and Reliable EDJ Dual-Power Fire Pump Sets

The EDJ Diesel Engine Fire Pump System is a powerful and reliable firefighting equipment designed for fire suppression and emergency rescue operations. It boasts high-performance capabilities in water extraction and pressure delivery, enabling rapid supply of large volumes of water. The system operates independently, ensuring its reliability even in challenging situations. With its lightweight and portable design, coupled with versatile functionality, the EDJ Diesel Engine Fire Pump System is suitable for various scenarios. Whether you are part of a fire department or an industrial enterprise, the EDJ Diesel Engine Fire Pump System is your indispensable rescue partner.

1.Powerful Performance: Equipped with a dependable diesel engine, the EDJ Fire Pump System provides abundant power to rapidly supply large volumes of water, ensuring outstanding fire suppression capabilities.

2.Effective Rescue: With its high-performance water extraction and pressure delivery capabilities, the EDJ Fire Pump System effectively controls fire spread, enabling you to swiftly extinguish fires and carry out emergency rescue operations with confidence.

3.Independent Operation: The EDJ Diesel Engine Fire Pump System operates independently, guaranteeing stability and reliability, so you can tackle emergency firefighting demands under any circumstances.

4.Flexibility and Portability: Designed to be compact, the EDJ Fire Pump System is easily deplorable and user-friendly. Its lightweight and portable nature empower you to access powerful firefighting support whenever and wherever needed.

5.Versatile Operations: With features such as automatic startup, remote control, and water supply for firefighting hoses, the EDJ Fire Pump System caters to diverse emergency requirements, ensuring efficient and seamless operations.

Whether you are part of a fire department, an industrial facility, a construction site, or a rural area, the EDJ Diesel Engine Fire Pump System is an indispensable firefighting asset. Count on the EDJ Fire Pump System to provide reliable support and swift containment of fires!