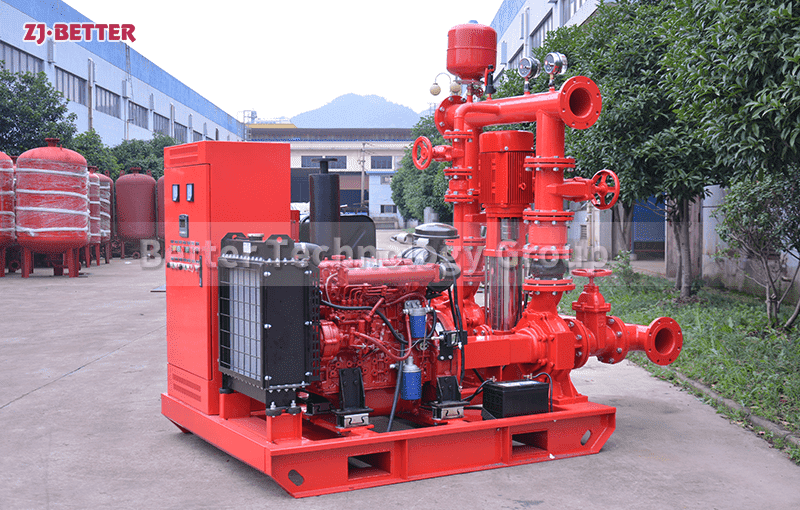

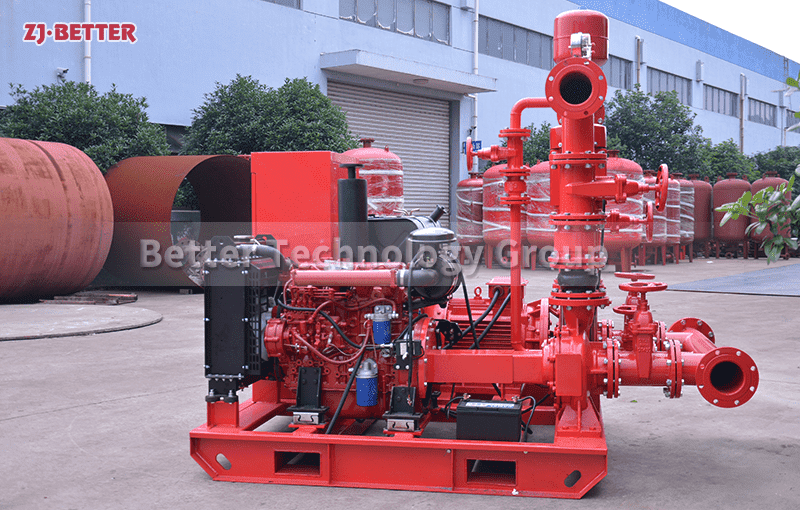

How does this fire pump maintain stable operation under high-pressure conditions?

This fire pump is built with high-strength materials and precision manufacturing to ensure stable operation under high-pressure conditions. Its advanced hydraulic design minimizes energy loss, enhancing pump efficiency and pressure output. Additionally, it features a high-performance sealing system that effectively prevents leaks, extending the equipment’s lifespan. Moreover, the pump unit is equipped with an intelligent monitoring system that continuously tracks operational status and adjusts parameters in real time, ensuring a stable and reliable water supply when it matters most.

This company specializes in the research and manufacturing of fire pump systems, offering efficient and reliable fire protection solutions to customers worldwide. The product range includes electric fire pumps, diesel engine fire pumps, constant pressure water supply systems, and complete fire pump sets, widely used in industrial, commercial, and municipal fire protection projects. All products comply with international fire safety standards and are known for high performance, durability, and intelligent control. Designed with compact structures and easy installation, they ensure stable operation in demanding environments while keeping maintenance costs low. Backed by advanced technology and a comprehensive quality management system, the company continuously provides customized solutions and professional technical support to safeguard lives and property.