How does it maintain stable and continuous high-pressure water supply?

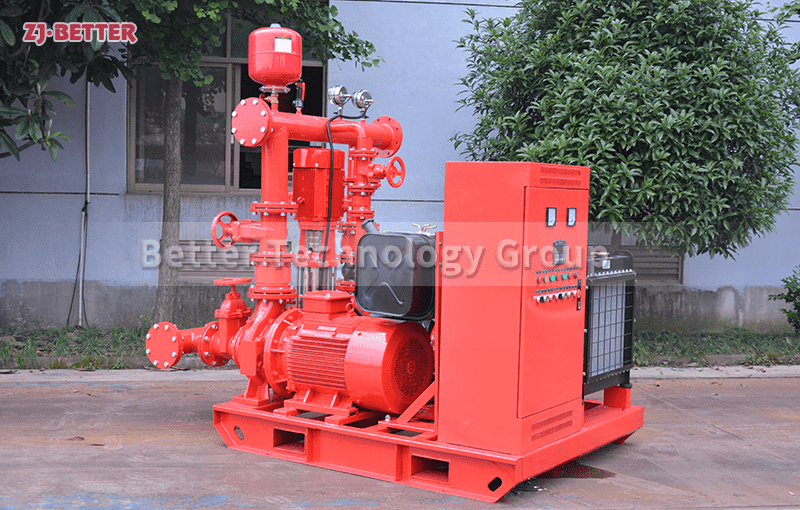

This integrated electric control fire pump unit features a high-efficiency pump design and advanced automatic control system, ensuring stable operation under high-pressure water supply conditions. The powerful motor drive delivers continuous high head and large flow output, meeting various demanding fire protection standards. With multi-point pressure monitoring and intelligent feedback adjustment, the system maintains consistent water pressure, greatly enhancing fire suppression efficiency and operational reliability.

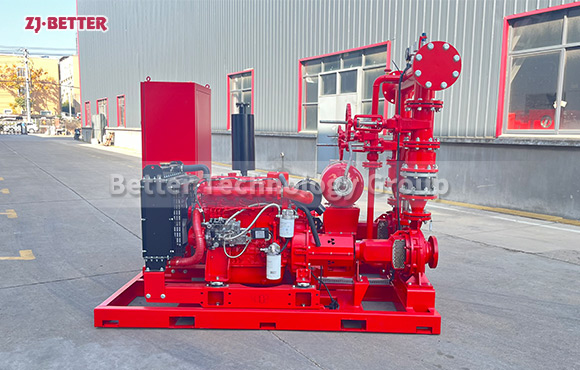

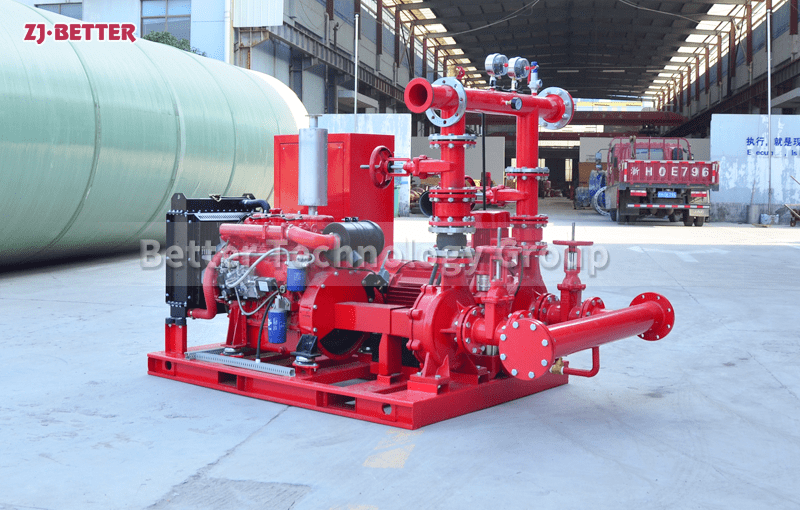

This company specializes in the development and manufacturing of high-performance fire pump systems, dedicated to delivering efficient and reliable fire protection solutions for buildings and industrial applications. The main products include electric fire pump sets, diesel engine pump systems, dual power fire pumps, constant pressure jockey pumps, and complete water supply units, all meeting international standards with features such as fast start-up, stable pressure, high efficiency, and compact structure.

These systems are widely used in high-rise buildings, industrial facilities, power plants, and chemical sectors. With strict quality control and rigorous testing, each system ensures optimal performance during critical emergencies.

Thanks to advanced technology, precision manufacturing, and a strong after-sales support system, the products are well-received and trusted by customers worldwide.