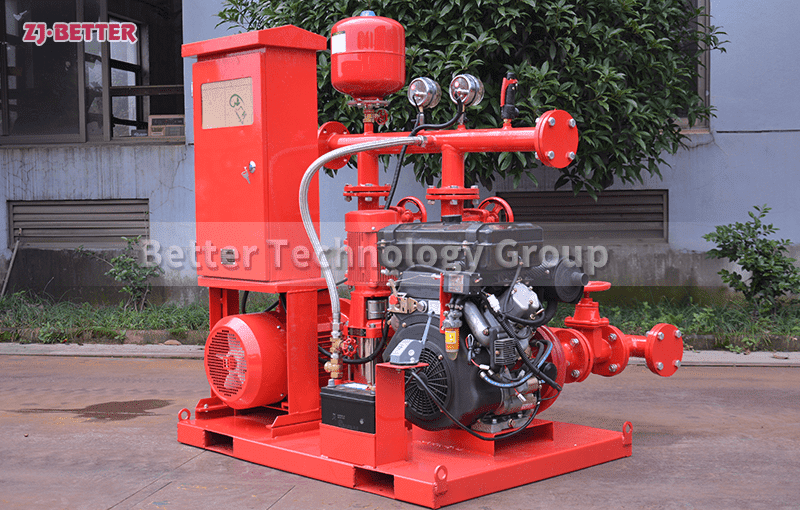

The long-shaft structure fire pump is a vertically installed fire pump specifically designed to address challenging water supply scenarios and complex operating conditions. It features a compact design, stable operation, high head, and high efficiency, making it particularly suitable for projects with deep water sources or limited space, such as high-rise buildings, deep well water extraction, municipal engineering, ports, underground water tanks, and chemical plants. The design philosophy of this pump system involves mounting the motor above ground level and transmitting power to the pump body at the water source via a long shaft. This addresses the issues of installation limitations or unstable operation associated with conventional horizontal pumps, ensuring reliable water pressure output during emergency fire situations and providing robust support for the entire fire protection system. One of the core advantages of this pump set is its excellent structural design. The multi-stage guide bearing structure ensures stable operation of the long shaft, significantly reducing vibration and noise during operation. The multi-point bearing support ensures the shaft remains stable and does not deviate. Additionally, the use of wear-resistant materials for the shaft sleeves and guide bearings ensures the pump maintains good mechanical condition even under prolonged high-load operation. Additionally, the pump body is made of high-quality cast iron or stainless steel, offering excellent corrosion resistance and pressure resistance, enabling it to operate long-term in environments with minor impurities or weakly corrosive liquids without damage. The pump body is partially submerged in the liquid, enabling automatic priming without the need for manual priming, improving startup efficiency, and saving labor time and costs.

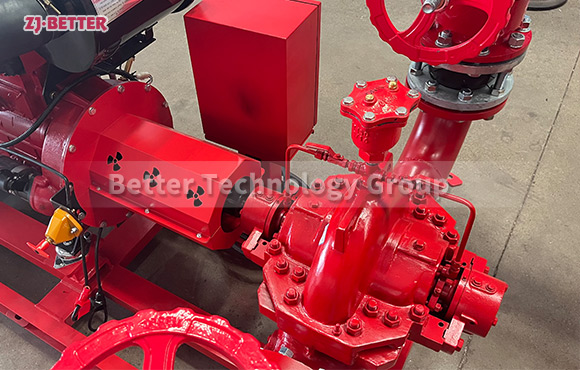

In terms of motor selection, long-shaft structure fire pumps are typically equipped with high-efficiency fully enclosed motors, which offer advantages such as high protection ratings, excellent heat dissipation, and strong overload capacity. The motor is connected to the pump body via a coupling, making installation and maintenance more convenient. The motor is installed above the pump room floor and does not come into contact with water, making daily maintenance easier and avoiding the risk of damage caused by water ingress into the motor, significantly improving the overall lifespan and stability of the system. In terms of transmission efficiency, the long-shaft design achieves high-efficiency power transmission through precision-machined shaft sleeves and couplings, minimizing energy loss and improving system operational efficiency. Additionally, the pump’s suction depth and head can be customized to meet specific customer requirements, ensuring optimal flow and pressure output across various application scenarios. The entire system undergoes dynamic balancing calibration to ensure smooth operation at high speeds with minimal vibration, thereby extending the pump’s lifespan and reducing equipment failure rates.

Safety performance is another key highlight of this fire pump. To address peak water demand during sudden fire incidents, the pump is equipped with an intelligent control cabinet supporting automatic start/stop, phase loss protection, overload protection, overvoltage/undervoltage protection, over-temperature alarm, and remote start functions, enabling integration with building automation systems. The control system can be integrated with the fire alarm system. Once a fire alarm is triggered, the pump unit will immediately respond and start operating, truly achieving the fire emergency response requirement of “water arrives before people do.” Additionally, the intelligent system can real-time record operational data and upload it to the management platform, enabling users to remotely monitor and manage maintenance, thereby improving operational efficiency. To enhance product durability, the pump shaft can be optionally equipped with 304 stainless steel material, suitable for industrial or coastal projects with higher requirements. In terms of sealing structure, the system employs a cartridge-type mechanical seal or multi-stage skeleton oil seal design to ensure no leakage even under high-temperature and high-pressure conditions, thereby preventing safety hazards to the control cabinet, motor, or surrounding equipment.

Long-shaft fire pumps not only offer superior performance but also flexible installation, making them particularly suitable for projects with limited space constraints. In scenarios such as deep wells or underground water tanks where the water level is below the pump room platform, these pumps can fully leverage their advantages. The motor and pump cover can be installed at the well opening or above the platform, while the remaining components can operate submerged in water, eliminating the need to construct complex intake channels or suction pipes, thereby significantly reducing civil engineering costs. Maintenance and servicing of the pump body are also highly convenient. Disassembling the pump shaft or guide bearings does not require the entire equipment to be removed; maintenance or replacement of components can be completed through segmented operations, greatly improving maintenance efficiency. Particularly in regions with stringent fire safety standards, such products often more easily meet local requirements, such as the stability, startup time, flow rate, and pressure maintenance specifications outlined in international fire safety standards like NFPA 20 and EN 12845, making them the preferred choice for fire main pumps in numerous engineering projects.

Energy efficiency and reduced consumption are also key features of long-shaft pump sets. Since the pump body is submerged in water for extended periods, it experiences minimal suction resistance. Combined with precise matching between motor power and pump body, this results in lower energy consumption during operation. In applications involving long-term operation or frequent starts and stops, the energy efficiency advantages of this pump translate into significant savings in operating costs. Additionally, to ensure a good working environment, the pump supports the use of stainless steel filters or pre-filtration devices to effectively prevent inlet blockages and ensure stable equipment operation. Many users have reported positive feedback after using this pump in projects such as urban water supply systems, fire pump stations, oil tank areas, port fire protection systems, and basement water sources, noting that its stability far exceeds that of ordinary horizontal fire pumps and that it can withstand extreme conditions of continuous high-pressure water supply.

Overall, long-shaft structure fire pumps have become an indispensable component of modern fire protection systems due to their outstanding performance in structural design, operational stability, installation flexibility, energy efficiency, and intelligent control. Whether in high-rise buildings, large industrial complexes, deep well pumping, port fire protection, or chemical storage tank areas—all high-risk zones—this pump system delivers robust performance and exceptional reliability, providing a solid foundation for the entire fire protection system. As global building fire safety standards become increasingly stringent, long-shaft structure fire pumps, with their superior performance and customizable capabilities, are increasingly becoming the preferred equipment for international engineering projects, with a promising future outlook.