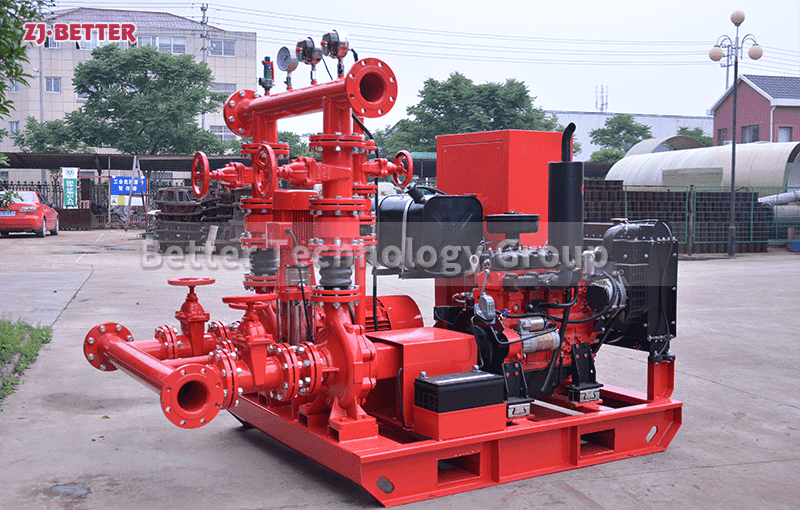

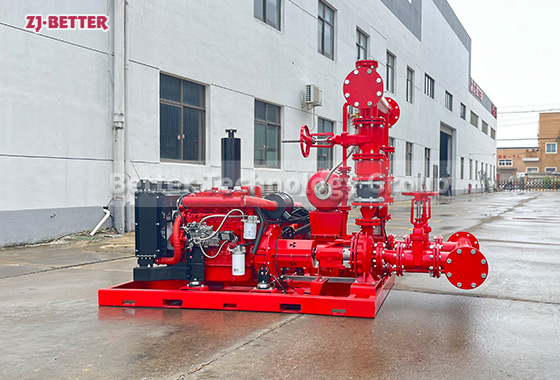

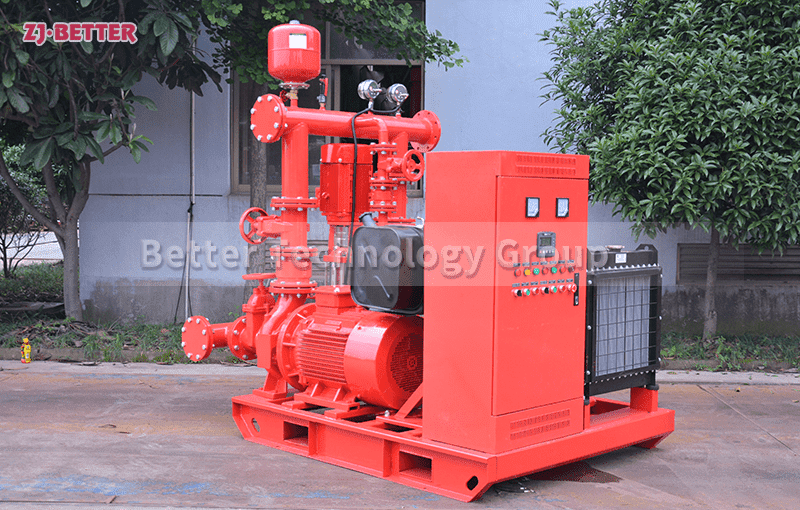

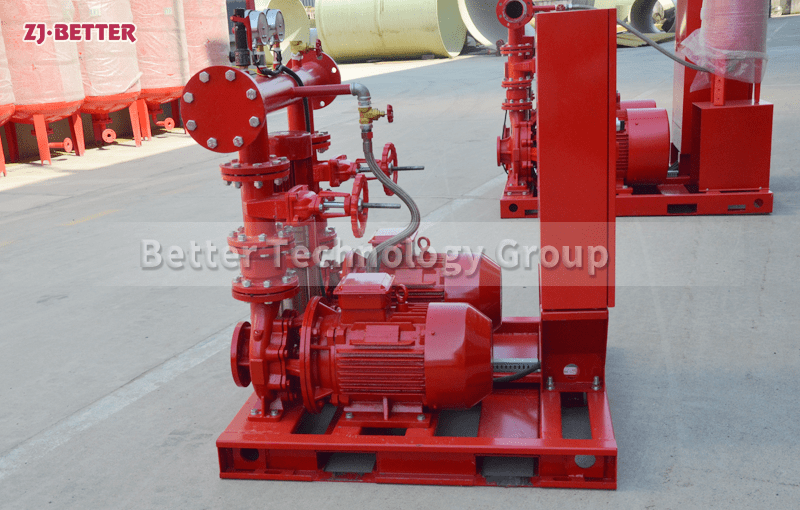

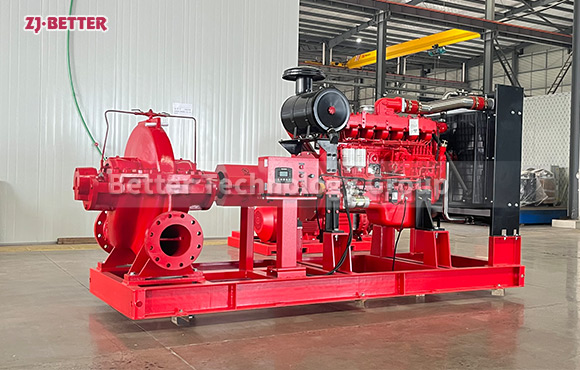

Diesel Fire Pump with Cooling System for Improved Operational Stability and Extended Lifespan

Reliable diesel fire pump with integrated cooling system ensures stable performance under high loads, extends engine lifespan, and provides continuous water supply during emergencies. Ideal for industrial and remote installations.

Diesel fire pump systems play a crucial role in safeguarding infrastructure and human life in emergency situations where water delivery must be both rapid and reliable. Among the various configurations available in the market, diesel fire pumps equipped with integrated cooling systems have emerged as a highly favored option due to their excellent operational stability and long-term durability. These advanced systems are designed to operate independently of grid electricity, ensuring uninterrupted functionality even in remote or disaster-affected areas. The addition of a cooling system enhances their ability to perform under continuous or high-load conditions without succumbing to overheating or mechanical fatigue, which is a common concern with traditional units. This type of diesel-driven fire pump is engineered for scenarios where high performance is non-negotiable—industrial sites, chemical plants, mining operations, oil refineries, airports, warehouses, and high-rise buildings that require a constant water supply during fire incidents. The diesel engine provides a robust and self-reliant power source, which makes the unit particularly useful in locations where electricity may not be available or reliable. More importantly, the inclusion of a radiator-style cooling system or heat exchanger ensures that the engine maintains optimal operating temperatures even during extended use, thereby preventing potential thermal damage. The cooling system typically consists of an air-cooled or water-cooled mechanism that absorbs engine heat and expels it through forced airflow or circulating coolant. This design prevents internal temperature spikes that could otherwise degrade the performance or longevity of the engine. With the assistance of a fan, radiator, coolant reservoir, and associated piping, the thermal management process becomes automatic and self-regulating. The real-world impact of this design is significant: it allows the diesel engine to function consistently at full load over long durations, which is often required in large-scale firefighting operations. Another critical advantage of this configuration is reduced maintenance frequency. Without a cooling system, diesel fire pumps are more likely to suffer from excessive wear, gasket failure, and oil degradation caused by sustained high temperatures. However, a built-in cooling system mitigates these risks, thereby extending the time between maintenance intervals. This results in reduced downtime, lower operational costs, and increased equipment uptime, all of which contribute positively to an organization’s risk management strategy. These systems also come with advanced safety and monitoring features, including automatic shutdown in case of overheating, low oil pressure alerts, and real-time temperature readings. These features not only protect the engine but also enhance user confidence during deployment. Many diesel fire pumps with integrated cooling systems also include automatic or manual start options, allowing seamless integration with sprinkler systems, hydrants, foam systems, or other emergency water delivery setups. From a structural standpoint, diesel fire pumps with cooling systems are designed to be compact yet rugged, often mounted on a steel base frame with anti-vibration mounts to ensure stable operation. This setup is especially useful in high-vibration environments such as offshore platforms or mobile firefighting units. The modular construction of these units also enables easier customization based on flow rate, pressure requirements, or site-specific installation needs. In terms of flow capacity and pressure, diesel fire pumps with cooling systems are available in a wide range of specifications—from small units with 30–50 GPM for localized protection, to large models capable of delivering over 1000 GPM for critical infrastructure. The integration of performance-tested centrifugal or split-case pumps further enhances the reliability of water delivery. Additionally, coupling mechanisms between the diesel engine and the pump are engineered for efficiency and minimal energy loss, often using flexible couplings or direct-drive alignment to ensure precise transmission. Sound insulation and exhaust systems are also integrated into the design to reduce noise output and ensure compliance with industrial noise standards. For installations near populated areas or indoor facilities, this feature becomes especially important. Another often overlooked benefit is the adaptability of these systems to various fuels—commonly diesel, but in some configurations, biodiesel or blended fuels can also be used. This enhances their environmental flexibility and allows easier compliance with local fuel regulations. Some modern models are also equipped with remote control and telemetry options, enabling users to monitor system performance, temperature levels, and fuel consumption from a control room or even a mobile device. This feature is particularly useful for fire protection systems that are part of a larger building automation or industrial control network. As a part of long-term planning, many facility managers now prefer to install diesel fire pump systems with cooling systems to meet NFPA-20 and UL/FM standards, ensuring global compliance and audit readiness. The certification of these systems often includes endurance testing, hydrostatic pressure evaluation, and performance curve verification to guarantee reliable operation in real emergencies. Logistics-wise, these systems are easy to transport and install, usually arriving as a pre-assembled skid-mounted unit requiring minimal on-site work. The installation process typically involves connecting the suction and discharge piping, fuel line, exhaust system, battery setup, and control panel wiring. Training operators to handle the system is relatively straightforward due to the built-in automation and simplified control interface, which usually includes start/stop buttons, temperature displays, and alarm indicators. Whether deployed in fixed positions or configured for mobile use, diesel fire pump units with cooling systems represent a vital investment in safety and operational resilience. Their ability to maintain continuous performance without overheating, combined with the ruggedness of diesel engines and the technological benefits of advanced cooling mechanisms, makes them a preferred choice for facilities prioritizing safety, compliance, and reliability. In an age where emergencies are unpredictable but increasingly frequent, having a dependable, standalone firefighting system is no longer optional—it’s essential. These diesel fire pump units deliver precisely that, ensuring that even in the most challenging conditions, water delivery for fire suppression remains stable, powerful, and uninterrupted.