Electric fire pump set has a wide range of applications

Fire pump refers to a clean water pump used for fire water supply, and a single water pump with a non-corrosive treatment medium temperature below 80°C. The pump unit is a joint operation of multiple fire pumps to ensure the quantity and stability of water supply. The electric motor fire pump set adopts multiple fire water pumps powered by electric motors. The general fire water supply environment is equipped with one electric and one diesel fire pump as the reserve water pump to ensure sufficient emergency water consumption.

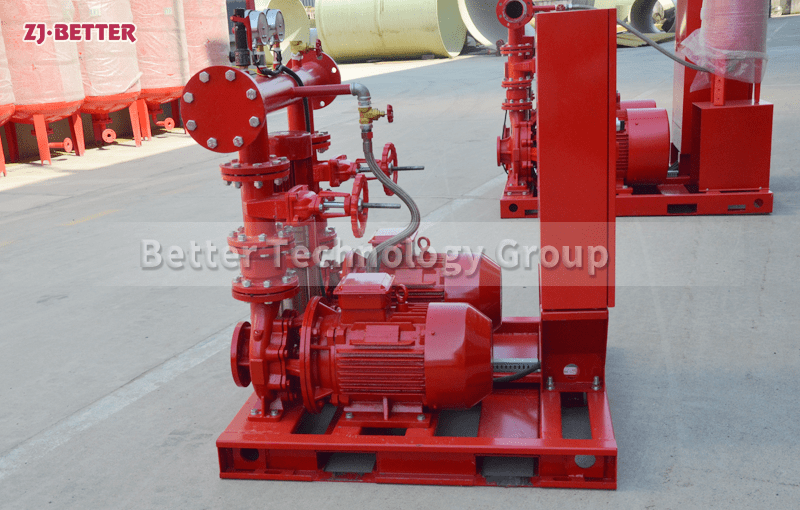

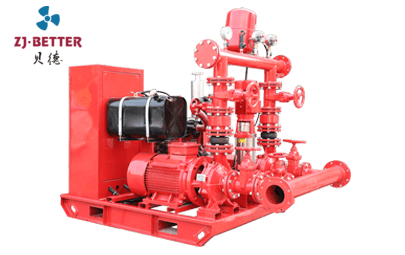

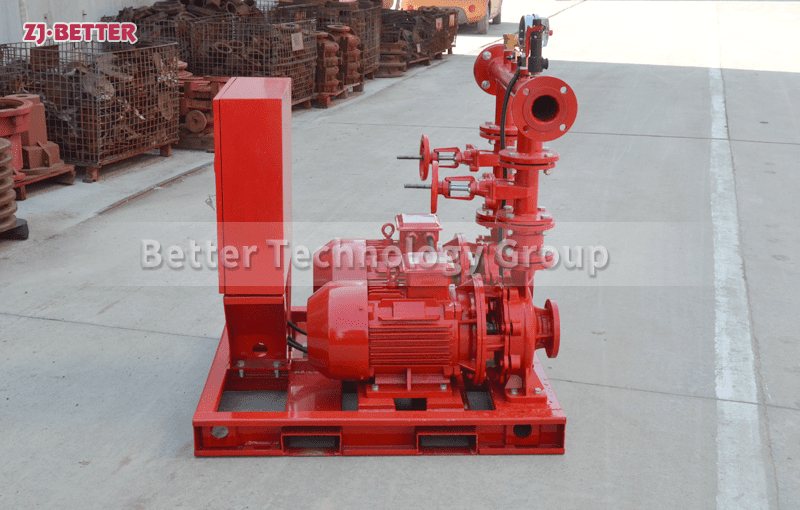

The electric fire pump set is powered by an electric motor, drives the fire pump, and outputs pressure water or air foam mixture for fire fighting. The pump set is mainly composed of a motor, a water pump, a transmission device, a common base and an instrument table. Its control cabinet is installed near the pump group for starting the motor.

The electric fire pump set has the advantages of quick start, reliable water diversion, stable operation, high degree of automation, wide range of pressure and flow, etc. It is an advanced and reliable fixed fire-fighting equipment. It is mainly used in fire water supply and foam fire extinguishing systems in industries such as petroleum, chemical industry, natural gas, power plants, textiles, wharves, gas stations, storage, high-rise buildings, etc.