Building Fire Booster & Pressure-Stabilizing System: The Ideal Choice for Stable Water Supply to Sprinklers and Hydrants

This building fire protection pressurization and stabilization system provides continuous and stable pressure for sprinklers and fire hydrants, and has advantages such as rapid response, high efficiency and energy saving, intelligent control and strong adaptability, ensuring that all types of buildings always maintain reliable fire water supply in emergency situations.

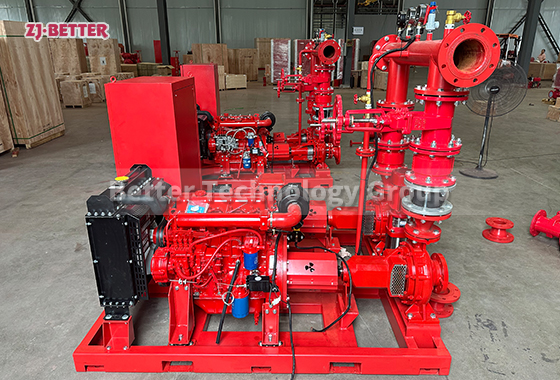

Building fire protection pressurization and stabilization systems play a crucial role in modern building fire safety systems. Their core task is to ensure that fire sprinkler systems and indoor/outdoor fire hydrant systems receive continuous, stable, and sufficient pressure and flow under all circumstances, thereby guaranteeing that fire extinguishing facilities can respond rapidly and be deployed at optimal performance in the event of a fire. Whether in commercial complexes, industrial plants, high-rise residential buildings, warehousing centers, transportation hubs, or large public buildings, pressurization and stabilization systems are considered the “pressure center” of the entire fire water supply system, and their stability and reliability directly affect the overall performance of the building’s fire protection capabilities. The water environment in modern buildings is extremely complex. Differences in floor height, pressure losses in different areas, and pressure demands from different equipment can all cause unstable water pressure. Therefore, simple municipal water supply or ordinary water pumps are no longer sufficient to meet the high pressure requirements of fire protection systems. The emergence of pressurization and stabilization systems is precisely to maintain the most suitable operating conditions for fire protection equipment amidst various pressure changes. The system typically consists of a booster pump, a pressure stabilizing pump, a pressure tank, an automatic control cabinet, piping components, and pressure monitoring equipment. It automatically monitors changes in pipeline pressure and activates corresponding equipment in real time to replenish or stabilize the pressure, achieving a fully automatic, unattended intelligent operation mode. Its design philosophy is to maintain the pipeline within a set pressure range with minimal energy consumption and automatically activate the main pump in case of a sudden pressure drop, thus achieving a highly efficient “pressure-responsive, on-demand-start” operating mechanism. One of the biggest advantages of the booster and pressure stabilizing system is its highly sensitive pressure monitoring and response capabilities. The system incorporates high-precision pressure sensors that can capture minute fluctuations in pipeline pressure in real time, such as sprinkler head bursting due to overheating, sudden opening of fire hydrant valves, or localized pressure relief in the pipeline. The equipment can react within seconds, automatically activating the pressure stabilizing pump or the main pump to replenish the pressure, ensuring the water supply system maintains a stable operating pressure and guaranteeing that fire-fighting facilities can achieve the required spray intensity and coverage within the first second. Traditional fire protection systems often suffer from problems such as difficulty in sprinkler activation, insufficient flow, low terminal pressure, and weak water output from fire hydrants due to the lack of pressure stabilizing devices. Booster and pressure stabilizing systems effectively avoid these issues, improving the operational efficiency of building fire protection equipment. Secondly, booster and pressure stabilizing systems offer high reliability, making them particularly suitable for high-rise buildings or large building complexes. As the number of building floors increases, the elevation difference leads to significantly greater pressure loss. Ordinary water sources are insufficient to meet the pressure requirements of high-rise sprinkler heads or fire hydrants. Booster and pressure stabilizing equipment, through precise pressure regulation and multi-stage booster pump configuration, ensures that water pressure is evenly distributed to every end of the system, guaranteeing the same stable water supply pressure for both the top and bottom floors. Furthermore, the system often employs a multi-pump combination, allowing other pumps to automatically take over operation when any pump fails, improving the redundancy and protection of the entire system and ensuring that the system does not lose its water supply capacity due to partial equipment failure during a fire. In terms of performance, the system not only prioritizes stability but also high efficiency and energy saving. To avoid energy waste and equipment wear caused by frequent main pump starts, the combination of a pressure-stabilizing pump and a pressure tank handles most of the daily pressure maintenance work, with the main pump only starting when a large amount of water supply is actually needed. This operating mode not only significantly reduces energy consumption but also extends the overall lifespan of the equipment and reduces maintenance costs. The reasonable capacity design of the pressure tank allows the system to avoid frequent motor starts when water usage is minimal or pressure drops, using pre-charged air pressure in the tank for buffering and pressure replenishment, achieving a more economical operating mode. In a true emergency, the booster pump can instantly deliver full power output, providing sufficient pressure to the sprinkler system, enabling the nozzles to form a good atomization effect and improving fire extinguishing efficiency. Regarding the control system, modern booster and pressure-stabilizing systems have fully adopted intelligent automatic control technology. By integrating PLCs, pressure sensors, flow monitoring modules, fault alarm units, and automatic switching modules, the equipment can autonomously determine pressure status, switch between different pump groups, execute automatic protection programs, record operating data, and send early warning signals to on-duty personnel. The control panel typically has multiple control modes, including manual, automatic, and remote, and can be connected to the building fire control center to achieve fire information linkage, enabling the entire fire protection system to operate collaboratively. The control cabinet is equipped with multiple safety measures, including short-circuit protection, leakage protection, phase loss protection, overload protection, and motor temperature protection, ensuring long-term stable operation without shutdown due to electrical faults. The equipment’s structural design also offers significant advantages. The system typically adopts a modular, integrated base structure, including the pump body, tank, valves, electrical control cabinet, and all piping interfaces. All components have undergone commissioning and pressure testing before leaving the factory; users only need to connect the power supply and piping to put it into use, greatly improving installation efficiency. Its compact footprint is suitable for projects with limited server room space, and the rational piping layout facilitates later maintenance and repair. Meanwhile, the pump body typically uses wear-resistant materials and a high-pressure-resistant design, giving it a longer service life and better corrosion resistance, adapting to different water quality environments, and ensuring the system operates at its optimal state for a long time. The booster and pressure stabilization system is also widely applicable, suitable for various types of buildings such as residential communities, hospitals, schools, shopping malls, hotels, industrial plants, logistics centers, airports, subway stations, and data centers. Especially in scenarios requiring high response speed and pressure stability of sprinkler systems, such as warehousing and logistics facilities and high-rise office buildings, these devices can fully leverage their advantages of rapid response and stable output, providing stronger fire safety guarantees for buildings. Furthermore, the system performs particularly well in addressing insufficient or fluctuating municipal water supply pressure. Through continuous pressure stabilization and efficient pressure replenishment, it ensures that the building’s fire protection system is unaffected by changes in external water supply, achieving truly independent and reliable water supply capabilities. In summary, building fire booster and pressure stabilization systems are indispensable core fire protection equipment in modern buildings. Their efficient and stable pressure control capabilities, intelligent monitoring and response systems, energy-efficient operating modes, highly redundant safety design, and highly adaptable structural configuration make them an ideal choice for ensuring a continuous and stable water supply for sprinkler and fire hydrant systems. As building scale continues to expand and fire protection standards gradually increase, booster and pressure stabilization systems, as key facilities for maintaining fire water supply capacity, will continue to play an irreplaceable role in building safety, providing more reliable, efficient, and safe fire protection for all types of buildings.