Performance Advantages and Applications of Self-Priming Fire Pumps in Emergency Fire Systems

Self-priming fire pumps possess powerful self-priming capabilities and high efficiency and stability, enabling rapid start-up and continuous high-pressure water supply without a foot valve. Their corrosion-resistant structure, energy-saving design, and automatic control system ensure rapid response and reliable operation during emergency firefighting. They are widely applicable to fire protection systems in high-rise buildings, industrial plants, warehouses, and ports, providing efficient protection for safe water supply.

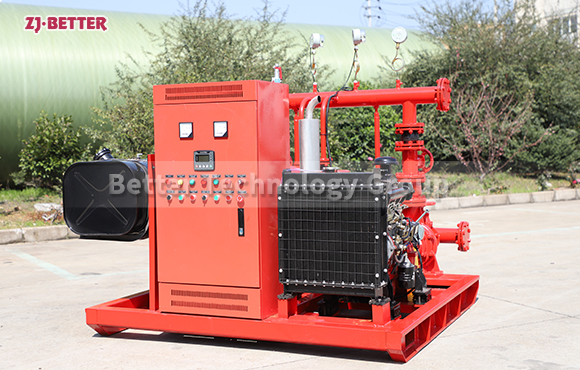

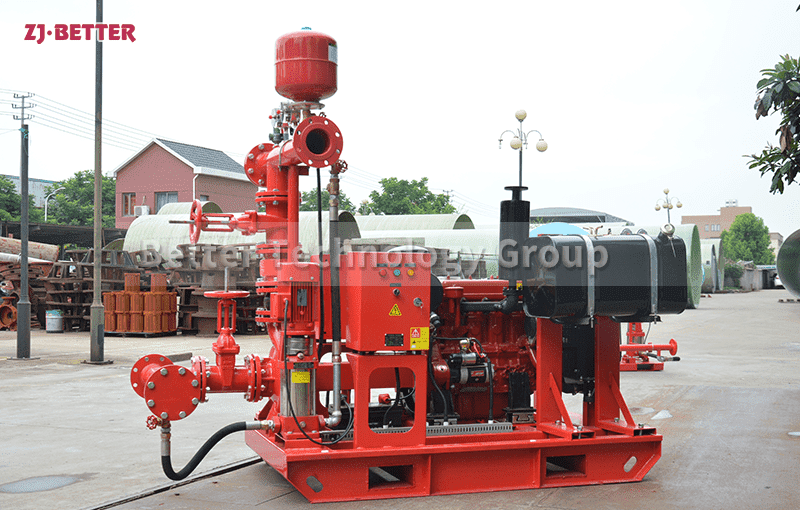

The performance advantages and application value of self-priming fire pumps in emergency fire extinguishing systems are reflected in their unique structural design, efficient working principle, and excellent reliability. This type of pump combines self-priming functionality with the high degree of compatibility with fire protection system requirements, making it an indispensable and important piece of equipment in modern fire protection systems. The core feature of self-priming fire pumps is their ability to store a certain amount of liquid inside the pump body, achieving automatic priming through the gas-liquid mixing principle. This eliminates the need for additional priming or a foot valve during startup, significantly shortening startup time and improving emergency response speed. In fire accidents, every second is crucial; rapid startup means that fire water can be extracted and delivered to sprinkler or fire hydrant systems in the shortest possible time, greatly improving rescue efficiency. Self-priming fire pumps typically employ high-efficiency impeller designs and optimized pump chamber flow channels, enabling the pump body to maintain stable flow and pressure output even in self-priming mode. This optimized fluid dynamics structure reduces fluid resistance and energy loss, thereby improving overall working efficiency while ensuring head. Its high efficiency is not only reflected in the operational phase but also in its stability during long-term standby. Since fire protection systems are often in a standby state for extended periods, the equipment must be able to immediately enter operational status upon emergency startup. Self-priming fire pumps, with their unique structural design and precision manufacturing process, can quickly self-prime and start even after prolonged periods of inactivity, ensuring the reliable operation of the entire system. In terms of materials, self-priming fire pumps are typically made of corrosion-resistant, high-strength alloy materials, and their internal flow channels are treated for rust and corrosion prevention, making them adaptable to various water quality environments, including municipal tap water, groundwater, and water sources with slight impurities. This durability not only extends the equipment’s lifespan but also reduces maintenance frequency, improving the overall system’s cost-effectiveness from an economic perspective. Compared to traditional centrifugal fire pumps, self-priming fire pumps do not require a foot valve or a separate priming device on the suction pipe. This simplified design significantly reduces installation complexity and maintenance difficulty. For fire protection systems with underground or long-distance water intake, traditional pumps often require manual water injection before startup, while self-priming pumps can automatically complete this process, performing particularly well in unattended or automated fire protection systems. Furthermore, self-priming fire pumps also have significant advantages in anti-cavitation performance. Thanks to its design incorporating fluid recirculation and gas-liquid separation technologies, the self-priming fire pump maintains stable operation even under conditions of high suction head or fluctuating liquid levels, effectively preventing cavitation damage to the impeller and thus improving equipment reliability and service life. In terms of performance parameters, the self-priming fire pump boasts a high suction head capacity, typically reaching 6 to 8 meters, with some high-performance models achieving even higher suction heads. This allows it to operate stably even in complex terrains or environments where the water intake point is lower than the pump position. Furthermore, its wide head range and adjustable flow rate adapt to the needs of fire protection systems of various sizes, from small and medium-sized buildings to large industrial parks, warehousing bases, and even high-risk locations such as port oil depots. Regarding power configuration, the self-priming fire pump can be driven by an electric motor or a diesel engine depending on the application scenario. Electric motor models are suitable for fixed building fire protection systems, offering advantages such as ease of operation and low maintenance costs; while diesel engine models can operate independently even without an external power source, making them an ideal solution for fire water supply during power outages. Regardless of the drive method, the pump set is typically equipped with an automatic control cabinet, enabling automatic start/stop, remote monitoring, and alarm linkage functions, ensuring the system’s intelligence and safety. In terms of noise control and vibration suppression, self-priming fire pumps significantly reduce operating noise through optimized rotor balance and vibration-damping installation structures, making them suitable for locations requiring quiet environments, such as hospitals, shopping malls, and high-rise residential buildings. Meanwhile, the equipment has a compact overall structure and small footprint, allowing for flexible layout based on site space, making it ideal for machine rooms or underground pump stations with limited installation space. In fire protection system design, self-priming fire pumps can be used not only as main pumps but also as backup or booster pumps, working in conjunction with sprinkler systems, fire hydrant systems, or foam extinguishing systems to form an efficient multi-stage water supply network. Their powerful self-priming capability allows them to quickly draw water from storage tanks, surface water sources, or mobile water tanks, providing continuous and stable water pressure for firefighting operations. Besides their widespread application in building fire protection systems, self-priming fire pumps are also widely used in industrial production processes for cooling, cleaning, and water supply, especially in industries such as petrochemicals, shipbuilding, metallurgy, and power generation. Due to their strong adaptability to media, ease of maintenance, and stable performance, they have become a preferred solution among general fluid transport equipment. From an energy-saving perspective, self-priming fire pumps consume less energy during operation. Their high-efficiency impellers and optimized flow channel design significantly reduce energy consumption per unit flow rate, aligning with current energy-saving and environmentally friendly technological development trends. Simultaneously, their ease of maintenance reduces long-term labor costs. The pump body is easy to disassemble and assemble, and key components such as mechanical seals, bearings, and impellers can be quickly replaced or repaired, minimizing equipment downtime and further improving the system’s continuous operation capability. Safety is a core aspect of fire pump design. Self-priming fire pumps are typically equipped with multiple protection devices, including overload protection, over-temperature protection, water shortage alarms, and automatic switching functions. When abnormal conditions are detected, the system can promptly issue alarms or automatically shut down, preventing equipment damage and safety accidents. This intelligent safety protection system ensures stable operation of the pump unit in various complex environments. Overall, self-priming fire pumps, with their unique self-priming structure, high-efficiency energy-saving performance, strong adaptability, and reliable automatic control system, have become the core of efficient and stable water supply in modern emergency fire extinguishing systems. They not only improve the response speed and operational reliability of fire protection systems but also demonstrate significant advantages in terms of ease of maintenance and economy. Whether in automatic sprinkler systems of high-rise buildings or in fire water supply systems of special locations such as industrial plants, warehouses, docks, oil depots, and airports, self-priming fire pumps have won widespread application and trust due to their superior performance. With the continuous development of fire protection technology and the popularization of intelligent control, the design of self-priming fire pumps is also constantly being optimized, evolving from traditional mechanical drives towards digitalization and intelligence. In the future, this equipment will play an even more important role in emergency water supply and disaster prevention systems, providing a solid guarantee for life safety and property protection.

管道泵(不锈钢304316L).jpg)