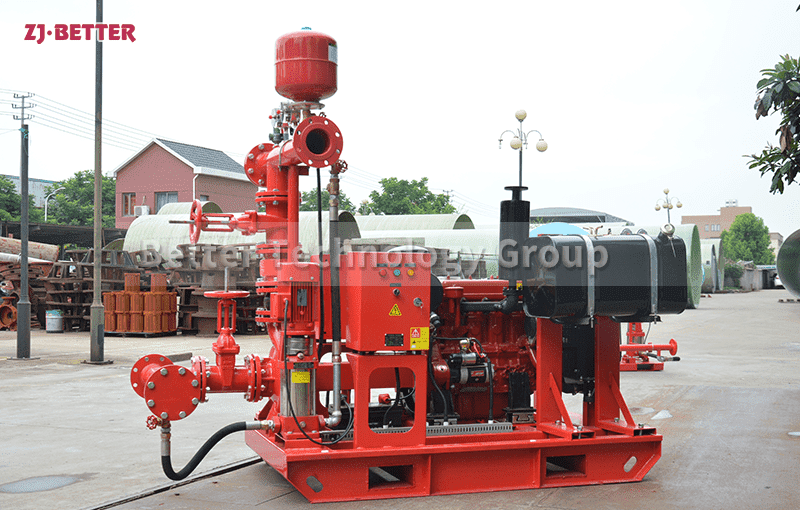

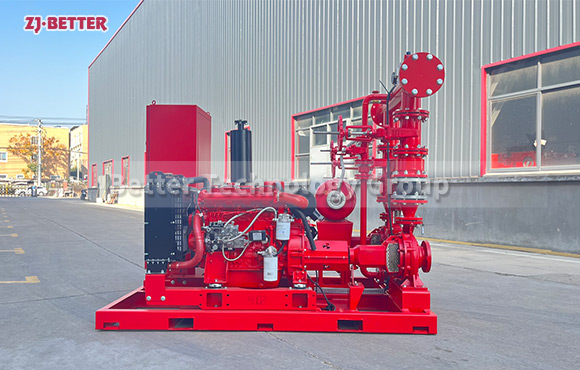

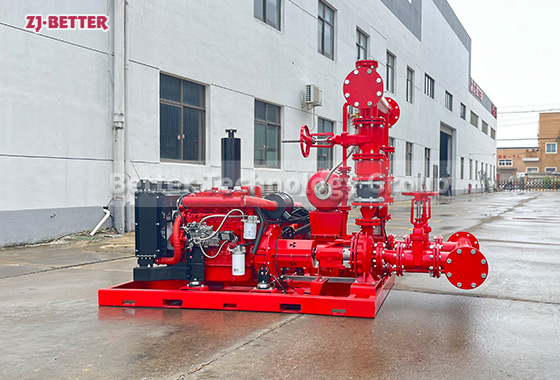

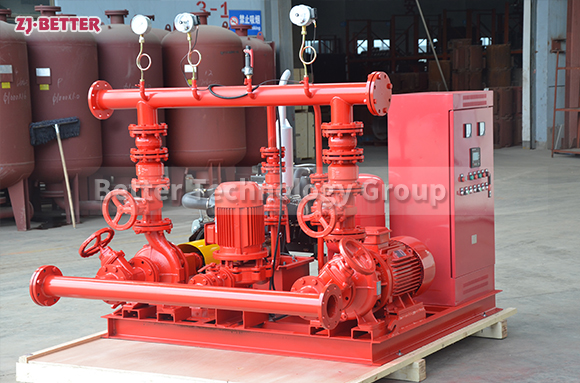

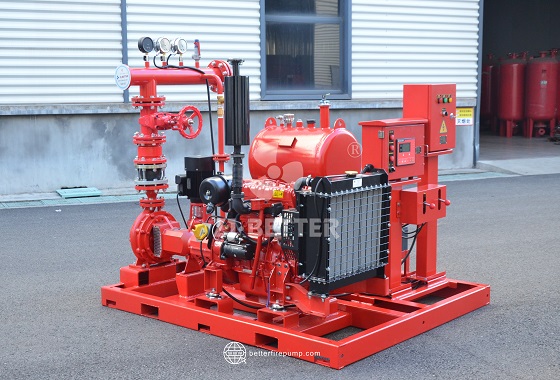

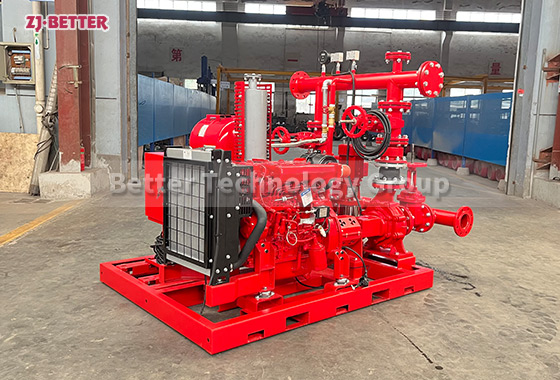

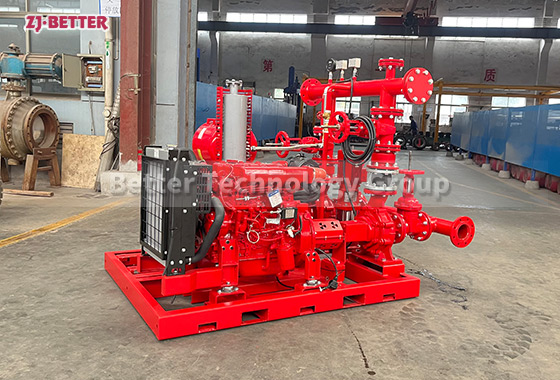

Diesel pump firefighting equipment for any occasion

For supplying water to automatic fire fighting systems and installations with hydrants. Fire pumps are part of the water supply to a fire sprinkler system and are powered by electricity, diesel or steam. It is used to extinguish fires over a period of time.

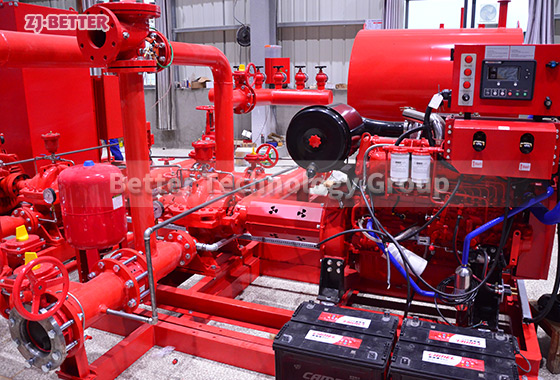

The fire pump is equipped with a control panel where you can adjust the flow of water and its power.

It is the most important part of fire protection system safety, in order to ensure the safety of people inside buildings, schools, ministries, hospitals, markets, shops, factories, malls or any infrastructure, a fire pump system must be installed to prevent the fires they enter.

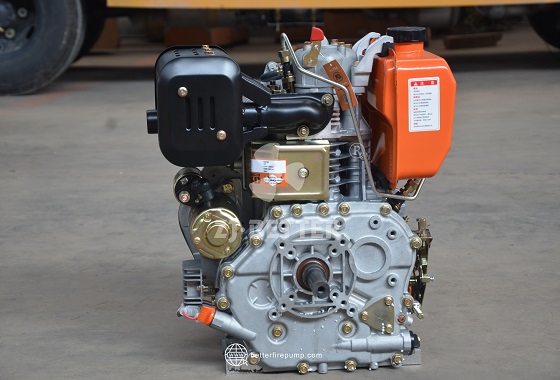

There are different types of fire pumps with different operations and capacities, for example; vertical and horizontal fire pumps powered by electric or diesel.

In order to match the service cycle of the fire pump, the inspection of the diesel engine and the fire pump should be regularly checked, and the parts to be replaced or repaired should be adjusted and corrected in a timely manner. We need to check the fuel tank reserves and oil quality of the diesel engine fire pump every day; the usage of the battery; the cooling system, etc., the pump shaft, impeller, bearing, and the wear of the water pipe and filter screen of the water pump. (Diesel engines of different brands may be different, and should be checked and maintained according to the specific model and structure of the diesel engine).