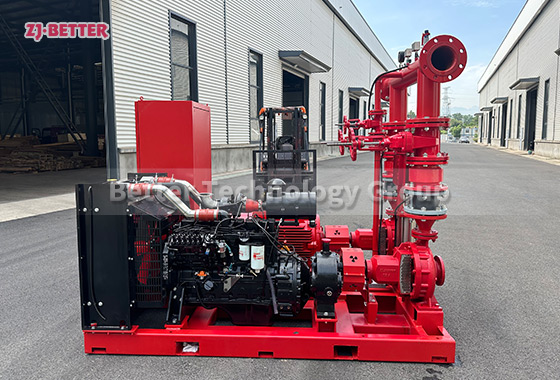

Diesel Fire Pump with Intelligent Control System for 24/7 Fire Protection

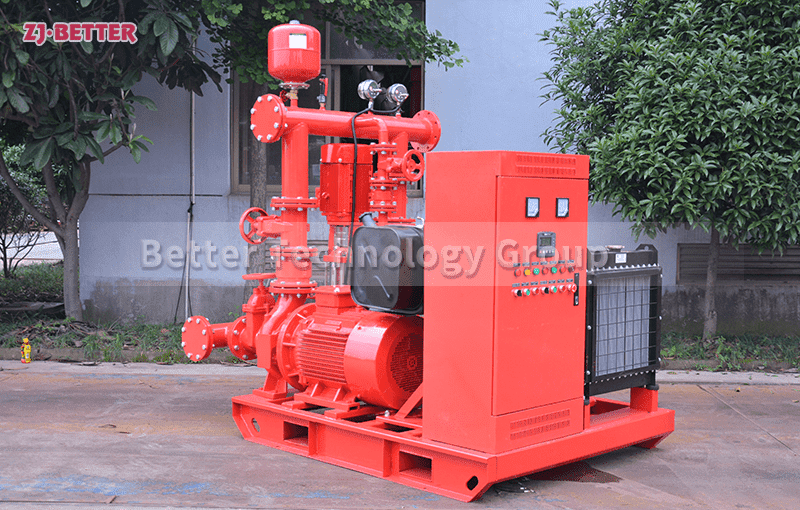

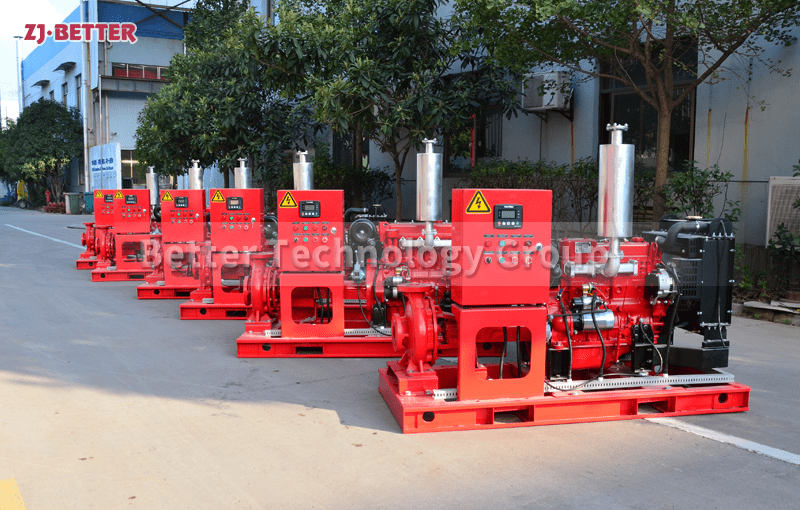

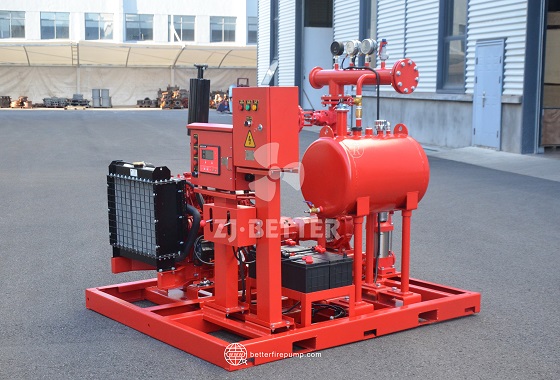

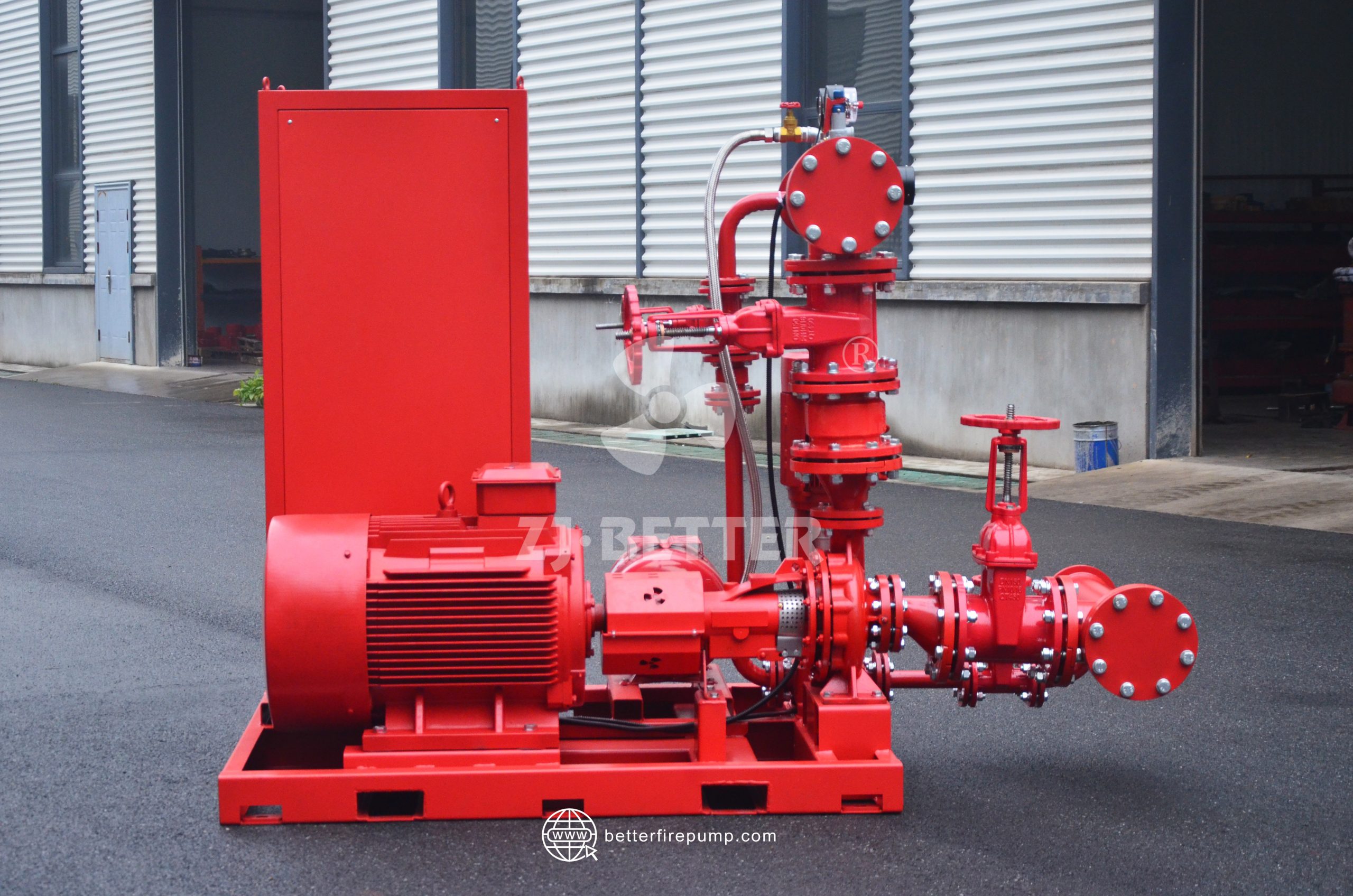

The highly reliable diesel fire pump is equipped with an intelligent control system that supports automatic start-up and multiple safety protections. It features high flow rate, high head, and stable continuous water supply capabilities, making it suitable for industrial plants, high-rise buildings, municipal and emergency fire protection systems.

Diesel fire pumps equipped with intelligent control systems are highly reliable water supply devices designed specifically for critical firefighting scenarios. They maintain a stable and continuous firefighting water supply capability even in the event of a power outage or power system failure, making them an indispensable component of modern fire protection systems. These diesel fire pumps typically use industrial-grade diesel engines as their power source, combining a high-efficiency centrifugal pump structure with an intelligent control system to achieve multiple functions such as automatic monitoring, automatic start-up, stable operation, and safety protection, fully meeting the needs of all-weather, unattended fire safety operations. Structurally, the diesel fire pump unit integrates the power system, pump body system, cooling system, fuel system, control system, and integrated base, with a compact and reasonable overall layout that facilitates transportation, installation, and maintenance. In terms of power performance, the diesel engine features low-speed, high-torque characteristics, enabling it to output strong power in a short time, ensuring the fire pump quickly reaches its rated operating condition in emergencies, and maintaining stable output performance even under high-head, high-flow conditions. Compared to electrically driven fire pump systems, diesel fire pumps are not limited by the external power grid, making them particularly suitable for locations with unstable power conditions or extremely high requirements for continuous fire protection, such as industrial plants, petrochemical parks, large warehousing and logistics centers, high-rise buildings, airports, tunnels, and municipal fire protection projects. In terms of pump performance, these fire pumps are typically manufactured using high-strength cast iron or ductile iron materials. Their internal flow channels are optimized for high hydraulic efficiency and low operating resistance, effectively reducing energy consumption and mechanical losses while extending the overall service life of the unit. The impeller undergoes dynamic balancing, ensuring smooth operation and keeping vibration and noise within reasonable ranges, maintaining good stability and reliability even under long-term continuous operation. The sealing structure primarily uses wear-resistant mechanical seals or packing seals, adaptable to different water quality conditions, reducing leakage risks and improving overall system safety. The intelligent control system is a core advantage of this diesel fire pump unit, integrating multiple sensors and control modules to achieve real-time monitoring of engine status, pump operating parameters, and the system environment. The control system can automatically detect changes in pipeline pressure. When the pressure falls below the set value, the system can quickly issue a start command, driving the diesel engine to start and putting the fire pump into operation. The entire process is rapid and logically clear, minimizing the response time of the fire protection system. Simultaneously, the control system supports multiple start-up methods, including automatic start, manual start, and remote start, flexibly adapting to different application scenarios and management needs. During operation, the intelligent control system can display key parameters in real time, such as speed, water pressure, water temperature, oil pressure, and battery voltage, facilitating maintenance personnel to fully understand the equipment’s operating status. In case of abnormalities, such as excessively high water temperature, excessively low oil pressure, or abnormal speed, the system will promptly issue audible and visual alarms and take corresponding protective measures according to the set logic to prevent equipment damage due to escalating faults. Some configurations also support automatic shutdown protection, extending equipment lifespan while ensuring safety. To meet the needs of all-weather operation, the diesel fire pump unit’s cooling system design also emphasizes reliability and adaptability. Common cooling methods include air-cooled radiators and water-cooled heat exchange systems, maintaining the engine within a reasonable operating temperature range under harsh conditions such as high temperatures, dust, or continuous operation. The efficient heat dissipation structure not only improves engine stability but also reduces the risk of malfunctions due to overheating, ensuring that the fire pump can be deployed at critical moments. The fuel system typically employs a stable and reliable fuel supply structure, and the fuel tank capacity is rationally configured to support the fire pump’s continuous operation under rated conditions for extended periods, meeting the continuous water supply time requirements of fire protection codes. Simultaneously, reasonable fuel consumption control helps reduce operating costs and improve equipment economy. From an installation and maintenance perspective, diesel fire pumps mostly adopt a modular, integrated base design. The entire unit is debugged and assembled before leaving the factory, requiring only foundation fixing, pipeline connection, and electrical wiring on-site, significantly shortening the installation cycle and reducing construction difficulty. Standardized interface design facilitates integration with existing fire protection piping systems and allows for future expansion and upgrades. In terms of maintenance, the equipment’s rational structural layout and easy-to-inspect and replace key components, with daily maintenance mainly focusing on checking the fuel, lubrication, cooling, and battery systems, resulting in controllable maintenance costs and suitability for long-term operation. In summary, diesel fire pumps equipped with intelligent control systems provide all-weather, highly reliable water supply for fire protection systems through reliable power output, efficient and stable hydraulic performance, advanced intelligent control, and comprehensive safety protection mechanisms. They do not rely on external power, have a fast response time, and are adaptable to a wide range of operating conditions. They can operate stably at critical moments in a fire, buying valuable time for firefighting and rescue operations, making them an ideal choice for improving overall safety and system reliability in modern fire protection engineering.