Electric Pump System for Building Fire Protection Enhancing Supply Stability

The building fire-fighting electric pump system adopts a high-efficiency electric drive and integrated structural design, which has the functions of rapid start-up, stable water supply and long service life. It is suitable for fire protection projects of high-rise buildings and public facilities, and effectively improves the reliability and safety of fire water supply systems.

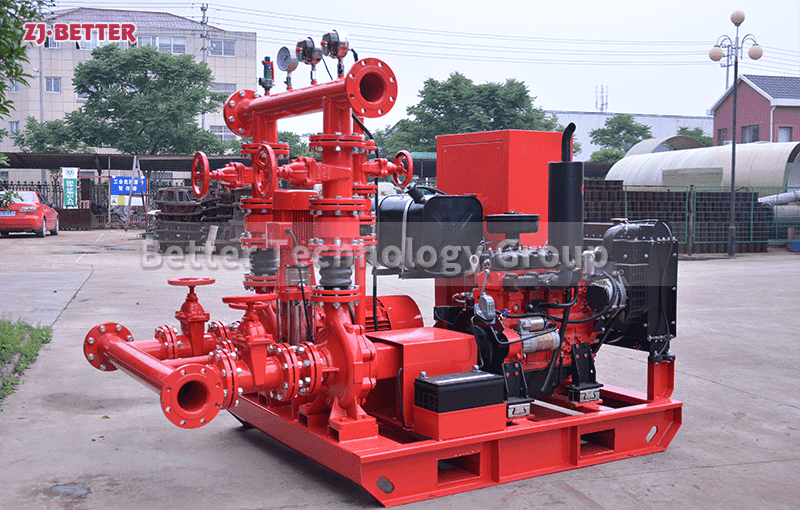

As a core component of modern fire-fighting water supply systems, the dedicated electric fire pump system for buildings plays a crucial role in ensuring a stable supply of sufficient fire-fighting water to the fire pipeline network during the initial stages of a fire and throughout the ongoing firefighting process. Its design is based on key requirements such as rapid response, stable water supply, safety and reliability, and long service life. The overall structure is powered by electric drive, combined with an efficient hydraulic model, robust mechanical structure, and a comprehensive control and protection system, enabling the entire system to maintain stable operation even in complex building environments and high-intensity usage scenarios. Structurally, the system typically adopts a horizontal or compact layout, integrating the fire pump body, motor, pressure stabilizing device, valves, piping, instrumentation components, and control unit onto a unified base. This not only effectively reduces the pump room footprint but also significantly lowers the difficulty of on-site installation and commissioning, making it particularly suitable for underground pump rooms, commercial complexes, high-rise residential buildings, hospitals, schools, office buildings, and various public building fire protection projects. This electric pump system excels in hydraulic performance. Through optimized impeller flow channel design and pump casing structure, it achieves a balanced output of high flow rate, high head, and high efficiency under rated operating conditions. This ensures stable pressure at the end of the pipeline network even when sprinkler and fire hydrant systems are activated simultaneously or multiple points are used, preventing insufficient water spray or system failure due to pressure fluctuations. The motor, as the power source, is an industrial-grade motor suitable for continuous operation and frequent starts, possessing excellent starting performance and load adaptability. It can achieve instantaneous start-up when mains power conditions permit, significantly shortening the response time of the fire protection system and gaining valuable time for initial fire control. The system also exhibits significant advantages in operational stability. Through scientific shaft design and high-precision assembly processes, it effectively reduces operating vibration and noise levels, minimizing the impact of long-term operation on the pump body and motor bearings, thereby extending the overall service life of the equipment. In building fire protection applications, equipment often needs to be on standby for extended periods. Therefore, this system has been specifically reinforced in terms of corrosion resistance, rust prevention, and environmental adaptability. The pump body and key components utilize corrosion-resistant materials or surface protective treatments, enabling them to withstand humid, high-temperature, or poorly ventilated pump room environments, ensuring smooth startup and stable operation even after long periods of inactivity. To further enhance water supply stability, the system is typically equipped with a pressure stabilizing device and related control logic. In non-fire conditions, it automatically maintains pipeline pressure, avoiding frequent start-stop of the main pump, thus saving energy and reducing mechanical wear. Simultaneously, it quickly switches to main pump operation mode when a fire signal is triggered, achieving high-flow fire water supply. The control system is a crucial component of the entire electric fire pump system. Through an integrated electrical control cabinet, it centrally manages motor start-up, operating status, fault alarms, and various protection functions. Automatic, manual, and remote control modes can be set according to actual project needs, meeting the management requirements of different building fire protection systems. The clear and intuitive operating interface also facilitates daily inspection and maintenance. In terms of safety performance, the system is equipped with multiple protection mechanisms, including overload protection, phase loss protection, voltage abnormality protection, and operational status monitoring. When abnormalities occur, it can promptly issue alarm signals to prevent the equipment from continuing to operate under adverse conditions, thereby ensuring the safety of the pump unit and the entire fire protection system. This electric pump system demonstrates excellent compatibility in practical engineering applications, flexibly adapting to different fire protection network designs. Whether it’s a single-pump system, a main/standby pump configuration, or a multi-pump parallel system, it can be customized according to building scale and fire protection regulations to meet different flow and pressure requirements. Thanks to its modular design concept, the system also has significant advantages in later maintenance and component replacement. Key vulnerable parts are rationally arranged, and maintenance space is ample, effectively reducing daily maintenance costs and downtime. In summary, the building fire protection electric pump system, with its efficient and stable water supply performance, reliable electric drive, comprehensive control and protection functions, and good engineering adaptability, has become an indispensable core equipment in various building fire protection projects. It can not only be quickly deployed in emergencies but also maintain stable performance during long-term operation and standby, providing a continuous, reliable, and efficient water source guarantee for building fire safety.