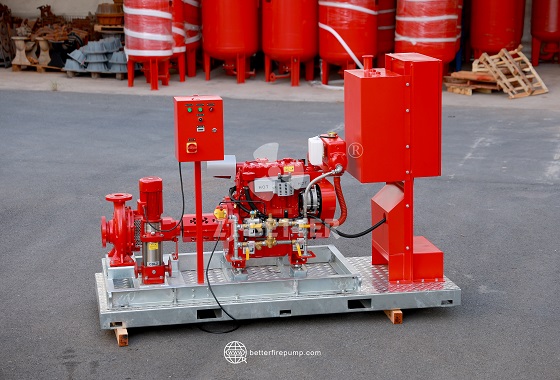

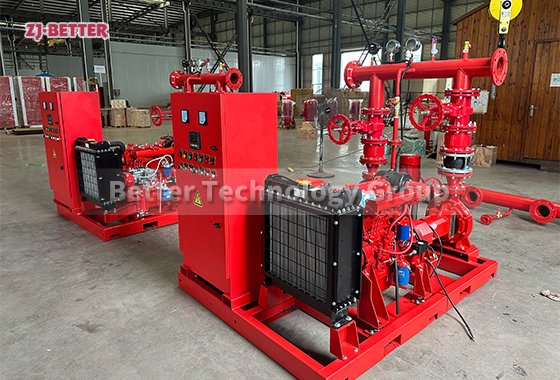

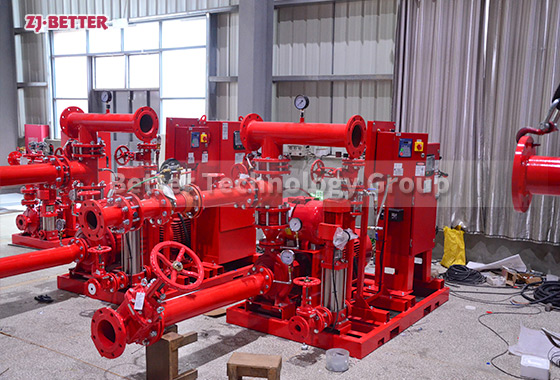

EDJ Standard Fire Pump Set

Scope of application of fire pump:

Equipment for warehouses, docks, airports, petrochemical, power plants, liquefied gas, textiles, ships, oil tankers and other occasions of a fire service.

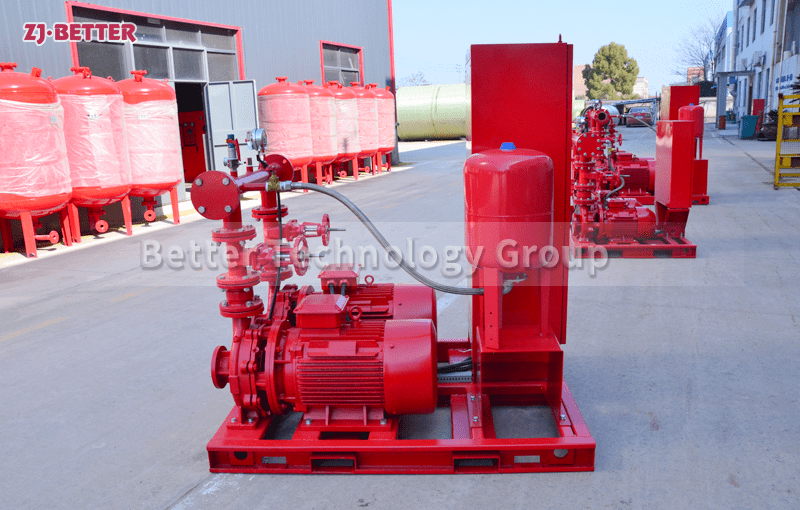

1. Electric pump, can use single stage pump, horizontal split case pump, end suction pump, multistage pump, material can be cast iron, stainless steel, and bronze impeller

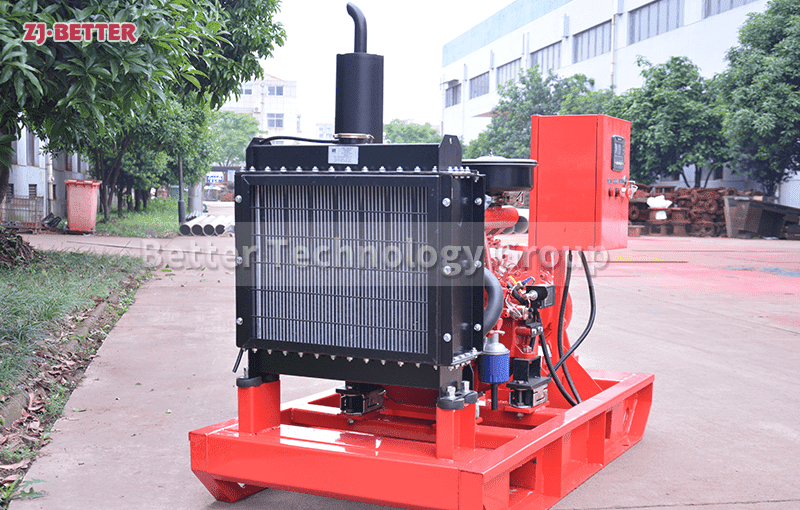

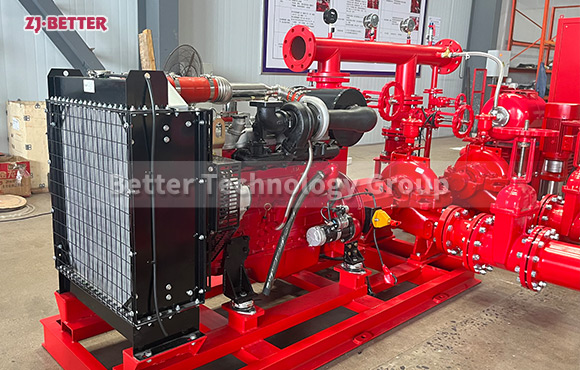

2. Diesel engine pump, with capacity and head equal to electric pump, with fuel tank, water tank£¬fan, control box.Diesel engine pump also can use end suction ,split case ,multistage pump can according to the flowrate ,head .

Different Diesel Model use different tank capacity.

3. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump

Jockey material casing :cast iron ,shaft and impeller SS304

4. Control panel: Auto Control of electric pump, diesel engine pump and Jockey Pump with overload, over current protection.

The control system has current, voltage, power display, and the operating status display of fire pump, diesel pump and steady pressure pump, diesel engine voltage, oil pressure, speed, running time display, manual pump control and automatic remote control.