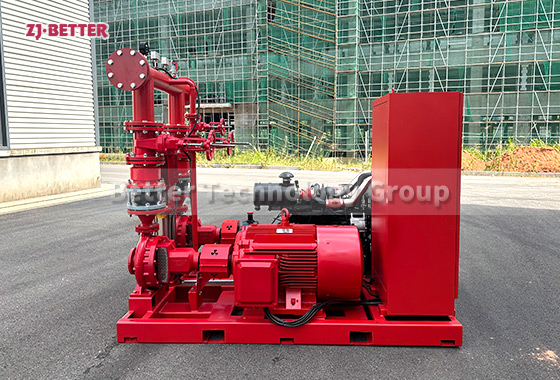

Robust Diesel Fire Pump System: Continuous and Reliable Water Supply When It Matters Most

High-performance diesel engine-driven fire pump systems are suitable for emergency water supply in power outages. Featuring high efficiency, durability, and intelligent control, they are widely used in industrial and commercial building fire protection, ensuring continuous water supply and fire safety in critical scenarios.

As an essential core firefighting equipment in modern buildings and industrial facilities, diesel-powered fire pump systems are widely used worldwide in various critical scenarios due to their unique advantages and superior performance. Powered by a diesel engine, this system combines a high-efficiency pump, a sophisticated control system, and a robust mounting platform, creating a complete fire water supply solution. It is particularly suitable for emergency situations with no power supply, frequent power outages, or high reliability requirements. Its greatest advantage lies in its independence from the utility power system, ensuring a continuous and stable high-pressure water supply even in extreme emergencies, making it a crucial piece of equipment for protecting personnel and property. This diesel fire pump system utilizes a horizontal or vertical centrifugal pump structure, typically equipped with a double-suction pump body, a durable pump casing, a thickened bearing support system, and a high-efficiency hydraulic model. These features ensure an efficiency exceeding 90% under rated operating conditions, fast startup, stable water supply pressure, and a wide flow range, ranging from 50m³/h to 1500m³/h, allowing for flexible configuration based on project requirements. The engine typically uses a high-speed diesel engine, offering powerful torque output and excellent fuel economy. Its torque characteristics are highly compatible with the fire pump’s performance curve, allowing it to quickly reach rated speed and maintain sustained operation. Even in high-temperature, high-humidity, dusty, or corrosive environments, it maintains stable power output, ensuring rapid system startup and sustained water supply. The engine also comes standard with an electronic monitoring system that displays key parameters such as speed, water temperature, oil pressure, and run time in real time, effectively improving system controllability and maintenance efficiency. The pump system utilizes a high-strength steel welded base for precise installation and excellent vibration resistance, effectively reducing noise and mechanical wear during operation. A highly flexible coupling or universal joint transmission structure is used between the pump unit and the engine, ensuring smooth transmission at high speeds and extending service life. Standardized inlet and outlet flanges ensure compatibility and facilitate connection to various pipe networks. Auxiliary components such as a stainless steel float valve, check valve, pressure relief valve, and surge tank ensure safe system operation and continuous water supply. The control system features both electric and manual starting. The main control box typically includes a built-in battery, starting relay, controller, and alarm module, enabling the diesel engine to start within 0.5 seconds, ensuring a prompt response to sudden fires. Some models also support remote monitoring and automatic start-up, making them suitable for unmanned fire pump rooms or integrated building intelligent systems. Furthermore, the control system includes an automatic inspection function, which periodically starts the pump unit for short operational tests to ensure the equipment is always in good condition. Regarding maintenance and operation, the diesel-powered fire pump system is designed with user-friendly operation and cost-effective maintenance in mind. The unit’s compact design and small footprint facilitate deployment in limited spaces. Key components such as the oil filter, air filter, water pump seal, and engine mount shock absorbers all utilize universal standards, making them easy to source and replace. The engine maintains a long maintenance cycle, with some high-end models offering over 1,000 hours of maintenance-free operation, significantly reducing the operator’s daily management burden. Through a strategic system layout, the pump unit seamlessly integrates with pressure-stabilizing pumps, electric pumps, and automatic sprinkler systems to create a complete, integrated firefighting solution. Diesel-powered fire pump systems are widely used in urban high-rise buildings, large commercial complexes, airports, rail transit, petrochemical facilities, warehousing and logistics, power substations, industrial parks, mines, tunnels, docks, offshore platforms, and other locations. Diesel fire pumps are particularly valuable in areas with weak infrastructure, complex environments, or unstable power supply. Their high performance, high reliability, strong compatibility, and 24/7 operation make them the preferred solution for emergency water supply systems in various fire protection projects. To meet the diverse needs of the global market, the system supports multiple design and certification standards, including NFPA20, UL/FM, EN12845, GB6245, and CE, ensuring broad global market adaptability and acceptance. Users can choose from a variety of engine brands, pump types, flow and head parameters, control system configurations, and installation methods based on project requirements, enabling truly customized design and rapid deployment, improving overall project efficiency and operational safety. In short, diesel-powered fire pump systems, with their high degree of independence, excellent hydraulic performance, reliable power output, comprehensive control and protection features, and wide adaptability, play a vital role in modern fire protection systems. It is not only a critical barrier in building safety systems, but also a reliable backing for emergency fire response, providing a solid guarantee for the safety of human life and property. With the rise of smart firefighting and intelligent buildings, diesel fire pump systems are continuously integrating the Internet of Things and remote monitoring technologies, developing in a more efficient, intelligent, and green direction, becoming an indispensable core component of future fire water supply systems.