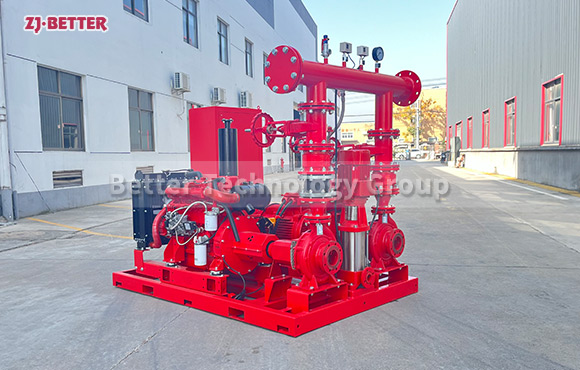

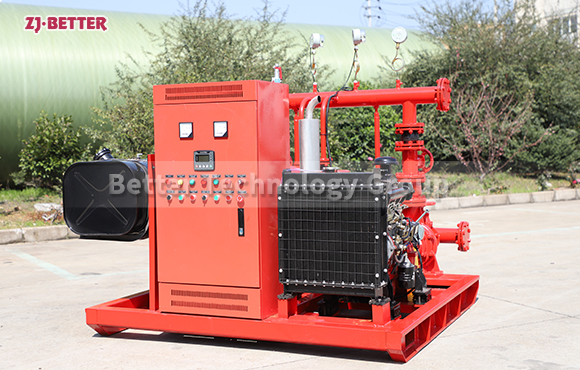

Coupled Horizontal Pump Design Optimized for Long-Term Fire Safety Reliability

Discover the performance and reliability of horizontal coupling fire pumps, engineered for efficient, continuous water supply in modern fire protection systems. Ideal for high-rise buildings, industrial facilities, and emergency scenarios requiring powerful and stable operation.

The horizontal coupling fire pump is a modern firefighting device that combines high efficiency, stability, and easy maintenance. It is widely used in various industrial, civil, and municipal firefighting systems. Its unique coupling structure and horizontal layout provide stable and reliable continuous power for firefighting systems. This pump unit, through optimized design, has achieved a significant improvement in overall performance, offering significant advantages in improving system efficiency, reducing energy consumption, extending equipment life, and simplifying maintenance. It is particularly suitable for firefighting scenarios that require long-term stable operation, rapid response, and strong anti-interference capabilities. Its structural features are primarily the direct connection between the pump and motor via a coupling, and its horizontal installation design offers a compact layout, robust structure, and smooth operation. The pump body is typically cast from high-strength cast iron or alloy, offering excellent pressure and corrosion resistance, and can withstand long-term operation in high-pressure and high-temperature environments. The rational configuration of the coupling effectively reduces vibration and noise, extending the service life of the pump shaft and motor bearings, while also avoiding the energy loss and tension maintenance issues common with belt drives, fundamentally improving energy efficiency. The motor utilizes a high-efficiency, energy-saving motor that meets international energy efficiency ratings. Thermal and overload protection systems effectively prevent equipment damage or interruptions caused by electrical faults, ensuring the pumpset maintains stable operation even in a variety of emergencies. Furthermore, these pumps are typically equipped with an automatic control panel that seamlessly connects to the fire protection system control center, enabling intelligent management features such as remote start and stop, parameter monitoring, and alarm notifications, significantly enhancing system safety and automation. In terms of performance, horizontal coupling pumps offer excellent flow and head characteristics, making them suitable for fire water supply systems of varying pressure levels. Precisely calculated and repeatedly tested hydraulic models optimize the impeller geometry and flow path design, minimizing hydraulic losses and improving overall pump efficiency. Flow rates range from tens to hundreds of cubic meters per hour, and head can be customized to meet project requirements, meeting diverse scenarios from single-story water supply to full-scale high-rise buildings. High-temperature and wear-resistant mechanical seals are typically used in the pumpset seal design to effectively prevent leaks and extend maintenance intervals. The pump shaft utilizes a heat-treated process and multiple sealing features to enhance stability and reliability under high-load operation. During installation and operation, the pump unit’s horizontal structure facilitates integration with existing pipe networks, streamlining the construction process and reducing footprint. Its modular design makes installation, commissioning, and ongoing maintenance more efficient and convenient, enabling rapid replacement of critical components even in emergencies, minimizing system downtime. In firefighting systems, horizontal coupling fire pumps are primarily used in automatic sprinkler systems, indoor and outdoor fire hydrant systems, and foam fire extinguishing systems. Their fast response, stable startup, and strong continuous water supply capacity effectively support rapid activation and continuous water supply throughout the firefighting network in the event of a fire, ensuring the safety of personnel and property. This pump unit, with its exceptional performance and reliability, has become an indispensable core component in firefighting systems, particularly in high-rise buildings, underground garages, petrochemical and energy bases, and airports. Furthermore, horizontal coupling fire pumps offer excellent operational cost control. Due to its simple structure, high efficiency, and easy maintenance, its energy consumption during operation is significantly lower than that of traditional horizontal belt-driven pumps. This also reduces significant maintenance labor costs and the risk of downtime, significantly improving the economic efficiency of the entire system. Environmentally friendly, this pump unit operates with low noise and vibration, minimizing impact on the surrounding environment, making it suitable for installation in noise-sensitive areas such as office buildings, shopping malls, and hotels. Depending on the application requirements of each project, this pump unit can also be integrated with a backup power system or diesel engine pump unit to ensure water supply during emergencies such as power outages and main pump failures, further enhancing the system’s emergency response capabilities and fault tolerance. From a manufacturing perspective, this pump unit utilizes advanced CNC machining and assembly technology, ensuring that each product undergoes rigorous quality control and performance testing, resulting in extremely high consistency and stability. Through the introduction of automated spray coating and anti-corrosion treatment processes, the product maintains excellent rust and corrosion resistance even in harsh environments such as high humidity and high salt spray, significantly extending the equipment’s service life. Against the backdrop of increasingly stringent global fire protection industry standards, this type of fire pump has passed numerous domestic and international certifications, such as ISO, CE, and NFPA. It is widely applicable to fire protection engineering projects under different national standards, providing excellent support for export to overseas markets. Overall, horizontal coupling fire pumps demonstrate superior performance in structural design, performance output, safety assurance, energy consumption control, installation and maintenance, and other dimensions. They are an ideal choice for achieving efficient, safe, and reliable water supply in fire protection systems in modern buildings and industrial facilities. Whether for new construction projects or retrofits and upgrades, this pump type, with its flexible configuration and high adaptability, can provide users with safer, more efficient, and more economical fire water supply solutions, standing out in the fierce market competition.