Energy-Efficient Twin Pump Fire Equipment for Versatile Installation Needs

Energy-saving twin fire pump unit suitable for multiple applications such as residential, industrial, and warehouse use. Features intelligent control, high efficiency, and reliable operation to enhance overall fire safety.

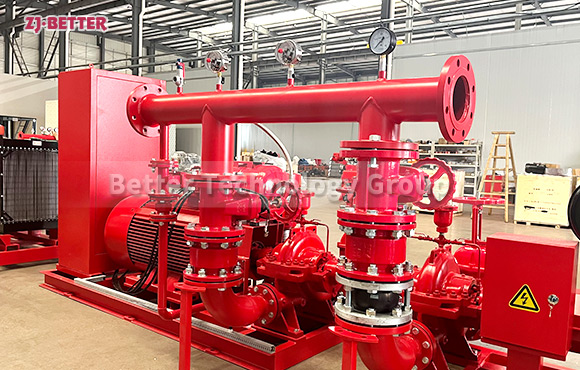

Energy-saving dual-pump firefighting equipment, a key component of modern building fire protection systems, boasts high efficiency, stability, and intelligence, making it widely applicable in diverse scenarios, including residential communities, high-rise buildings, industrial plants, warehouses and logistics centers, municipal facilities, airports, ports, and the petrochemical industry. Compared to traditional single-pump systems, dual-pump configurations are not only more compact and rational in structure, but also offer significant functional advantages, particularly in energy savings and system redundancy. This equipment utilizes dual-pump parallel operation, enabling on-demand start and stop operations through an automatic control system. This ensures the firefighting system’s real-time responsiveness while significantly reducing inefficient energy consumption. When the system is operating at low load or during inspections, only one pump is required to meet basic water pressure requirements. In the event of a fire, the system automatically switches to dual-pump coordinated operation, providing rapid response and full-power water supply, ensuring maximum firefighting efficiency. This design not only optimizes system operating costs but also extends the service life of each pump, ensuring sustainable and economical operation.

Furthermore, this firefighting equipment features a modular installation design, adaptable to installation in equipment rooms of varying sizes. Whether for new projects or renovations of existing facilities, the system is adaptable and quick to deploy and maintain. The unit’s base is constructed of thickened carbon steel and treated with an anti-corrosion spray, ensuring high strength and stability in complex environments such as humidity, dust, and high temperatures. All pipe connections utilize high-pressure flanges for enhanced seismic resistance, ensuring reliable operation even in earthquakes and severe vibration. The control system utilizes a PLC intelligent module, which, when combined with a touch panel or remote terminal, enables a three-in-one control mode combining fully automatic control, manual operation, and remote monitoring. The system features numerous intelligent functions, including automatic inspections, real-time alarms, fault self-diagnosis, and automatic switching, significantly enhancing system safety and management efficiency.

The device is equipped with multiple sensor units, including pressure sensors, flow switches, current monitoring, and temperature sensing, forming a complete real-time data acquisition system. Connecting to a host computer or cloud platform via a communication module, users can remotely view the pump unit’s operating status and historical data via a PC or mobile app. This not only enhances visibility into equipment operation and maintenance, but also facilitates data analysis and maintenance decision-making, reducing the overall lifecycle cost of the equipment. The product’s motor utilizes a high-efficiency, energy-saving motor and is equipped with a soft start or variable frequency starter. This allows for dynamic speed adjustment based on actual on-site water usage, preventing water hammer while reducing energy consumption and improving system responsiveness. The pump body is constructed of high-strength ductile iron or stainless steel for corrosion resistance and compatibility with a wide range of water qualities, including tap water, recycled water, and softened water. The impeller is dynamically balanced for smoother operation, low noise, and minimal vibration, ensuring operational stability while also enhancing the user experience.

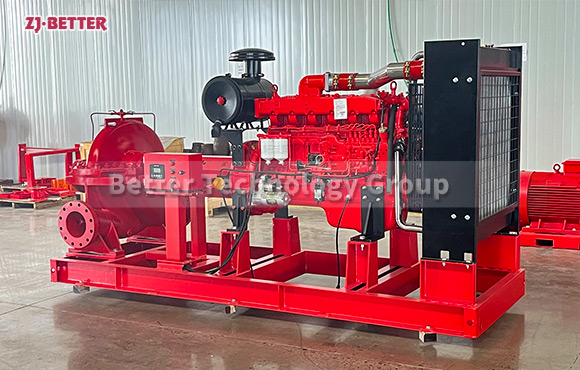

Technically, the device features a backup power supply port, enabling seamless switching between mains power, a generator set, and a UPS, ensuring continuous power supply in the event of a fire. A remote fire control interface is also included, enabling communication with the fire alarm host and building automation system. Upon receiving a fire signal, the pump automatically activates, creating a complete closed-loop response mechanism for automatic fire extinguishing. Whether it’s a sprinkler system, a fire hydrant system, or a foam fire extinguishing system, this device can be precisely integrated, providing a solid hydraulic guarantee for fire safety throughout the building. Notably, this dual-pump system has achieved multiple international certifications in terms of energy conservation and environmental protection, complying with current green building and carbon emission management standards. This provides strong support for enterprises to achieve low-carbon transformation and improve project ratings. Its silent design and low-vibration structure make it widely applicable in environmentally sensitive locations with stringent noise control requirements, such as schools, hospitals, office buildings, and museums.

For installation and commissioning, the equipment undergoes a complete set of pressure tests, electrical inspections, and system linkage verification before leaving the factory. On-site, users only need to connect the inlet and outlet pipes and power supply for rapid commissioning, significantly reducing installation time and labor costs. Regarding maintenance, the equipment comes with a comprehensive maintenance manual and a regular maintenance reminder system, allowing users to regularly check key components such as filters, electrical connections, and pressure stability, thereby enhancing the reliability and service life of the entire system. This dual-pump system is particularly suitable for high-risk areas requiring 24/7 fire protection. In the event of an emergency, if one pump unit fails, the other unit automatically switches to operation, ensuring uninterrupted water supply. This dual-unit backup mechanism provides extremely high safety redundancy for large-scale projects and is a preferred solution for today’s high-standard fire protection projects.

In summary, energy-saving dual-pump firefighting equipment not only outperforms traditional systems in performance parameters, but has also earned wide recognition in firefighting engineering through its intelligent control, modular structure, multi-scenario compatibility, and robust operational stability. With the advancement of urbanization and the increasing fire protection requirements for buildings, this type of product will play an increasingly important role in the configuration of future building firefighting systems. Choosing an efficient, intelligent, and safe dual-pump system is not only a safeguard for the safety of life and property, but also a positive response to the concept of sustainable development in the future. By continuously optimizing its structural design and control logic, this equipment is gradually leading the industry toward higher energy efficiency, higher reliability, and higher intelligence, becoming an essential and important piece of equipment for upgrading modern building firefighting systems.