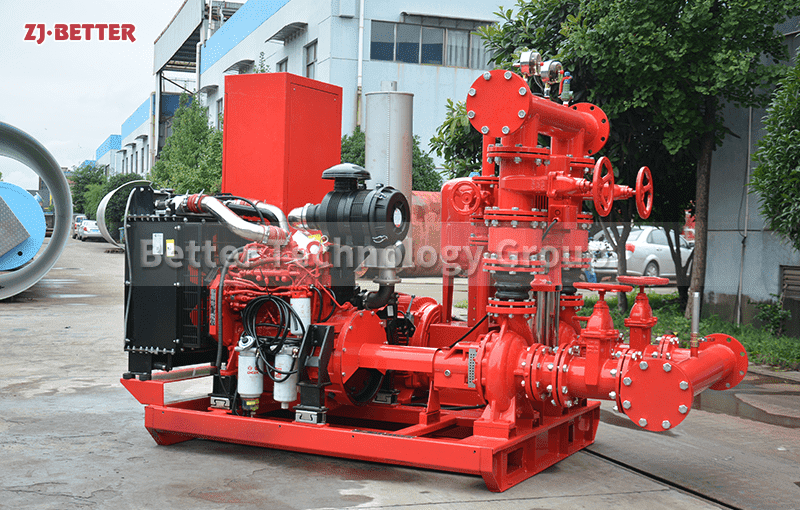

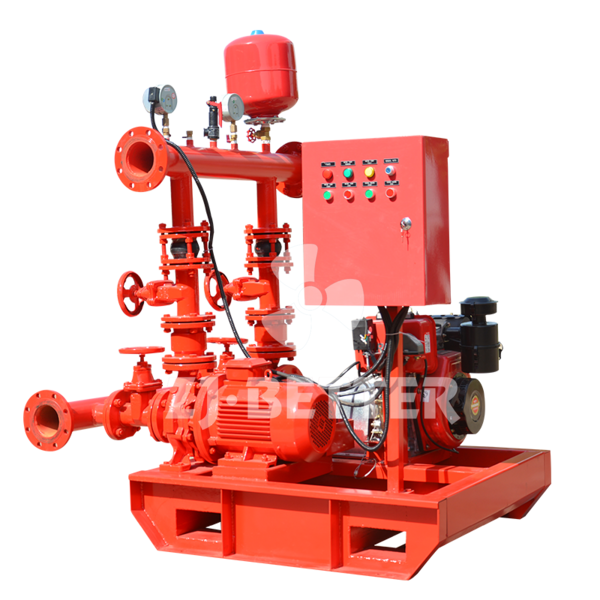

Structural Features and Operating Performance of Diesel Fire Pump Units with Integrated Cooling System

The integrated cooling system diesel fire pump unit has independent power, high-efficiency cooling and stable continuous operation capabilities. It is suitable for fire protection systems without external power supply and with high reliability, and is widely used in industrial, building and emergency fire water supply projects.

The integrated cooling system diesel fire pump unit is an emergency water supply device specifically designed for high-reliability fire-fighting water supply needs. Its core advantages lie in stable power output, efficient heat dissipation structure, and the ability to operate continuously for extended periods under complex conditions. It is widely applicable to building fire protection, industrial fire protection, and infrastructure fire protection systems in environments with unstable mains power or without external power supply. This type of unit uses a diesel engine as its drive power source. Compared to electric fire pumps, it is not limited by external power conditions and can be quickly put into operation in the event of sudden power outages, natural disasters, or grid failures, ensuring reliable water supply to the fire protection system at critical moments. The integrated cooling system is a crucial component of the diesel fire pump unit. Its design directly affects the stability and service life of the entire unit under high load and long-term operation. Through an efficient radiator, a reasonable air duct layout, and cooling capacity matched to the diesel engine’s power rating, the engine is maintained within a reasonable temperature range during continuous operation, preventing power attenuation, malfunctions, or accelerated aging of components due to overheating. These units typically employ an integrated skid-mounted structure, centrally housing the diesel engine, fire pump, radiator, control system, and piping system on a steel base. This compact and integrated design facilitates transportation and installation, as well as on-site maintenance and management. The deep integration of the cooling system with the diesel engine is a key performance advantage. By optimizing the coolant circulation path, increasing the heat dissipation area, and improving airflow efficiency, the unit can maintain stable operation even in pump rooms with high ambient temperatures or limited ventilation, meeting fire safety regulations for continuous operation time. The fire pump itself is usually designed with a high-efficiency hydraulic model, minimizing hydraulic losses while ensuring rated flow and head. This allows the diesel engine’s power output to be more effectively converted into fire-fighting water supply capacity, achieving rapid, stable, and high-flow-rate water supply during fires. Diesel fire pump units also exhibit significant advantages in starting performance. Equipped with a reliable starting system and automatic control logic, they can quickly complete the startup process upon receiving a fire signal or abnormal pipeline pressure command, reaching rated speed and operating status within a short time, ensuring that fire-fighting water supply is not affected by startup delays. The integrated control system plays a crucial role in the unit’s operation. By monitoring and managing key parameters such as speed, oil pressure, water temperature, and voltage in real time, it ensures the equipment remains in a safe and controllable state. In the event of abnormal operating conditions, the system can promptly issue alarms and take protective measures to prevent the escalation of the fault and maintain the overall reliability of the fire protection system. The integrated cooling system diesel fire pump unit excels in continuous operation. Its design fully considers the long-term water supply requirements that may arise in fire scenarios. By enhancing cooling capacity, optimizing the lubrication system, and selecting durable key components, the unit can maintain stable output for extended periods without interrupting water supply due to temperature rise or performance degradation. This characteristic makes it irreplaceable in fire protection systems for high-risk locations such as large industrial parks, petrochemical facilities, logistics and warehousing bases, and large public buildings. The rational structural layout is also a significant advantage of this type of unit. The radiator is typically positioned to facilitate airflow and forms an efficient cooling loop with the diesel engine, while preventing heat accumulation inside the equipment, thereby improving the overall system’s thermal stability and operational safety. The unit’s base and support structure possess excellent strength and vibration damping performance, effectively reducing vibration and noise generated during operation. This minimizes the impact on the pump house structure and surrounding environment, contributing to improved equipment stability and comfort. Ease of maintenance is another major performance advantage of the integrated cooling system diesel fire pump unit. The modular design ensures clear layout of key components and ample maintenance space, making daily inspection, maintenance, and troubleshooting more efficient and ensuring optimal performance over extended periods. Through proper selection and system configuration, this type of unit can form a multi-layered fire water supply system with electric fire pumps, pressure-stabilizing pumps, and fire control systems. Each component performs its specific function under different operating conditions, meeting daily pressure maintenance needs while providing robust emergency water supply support. From a system reliability perspective, the integrated cooling system diesel fire pump unit provides solid and reliable technical support for fire water supply systems by reducing reliance on a single energy source, enhancing continuous operation capabilities, and strengthening stability under high-temperature conditions. This effectively reduces the risk of water supply interruptions due to equipment failure or environmental factors. In summary, these units, with their mature diesel power technology, efficient and reliable integrated cooling system, and comprehensive control and protection functions, demonstrate outstanding product advantages and application performance in modern fire protection engineering. They are an indispensable and important piece of equipment in fire protection projects that pursue high safety levels and high system reliability.