Powerful Support for Fire Safety: High-Temperature and Corrosion-Resistant Diesel Fire Pump Performance

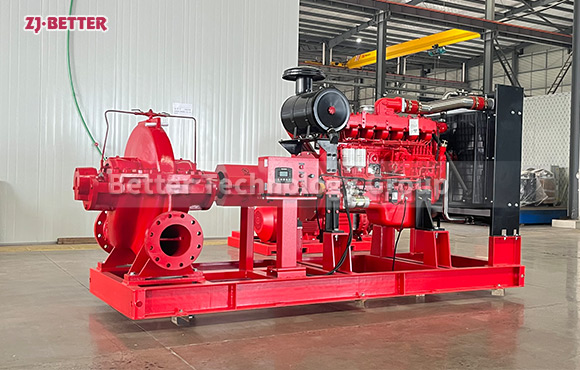

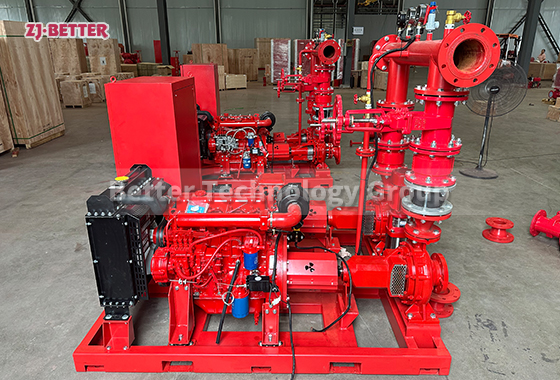

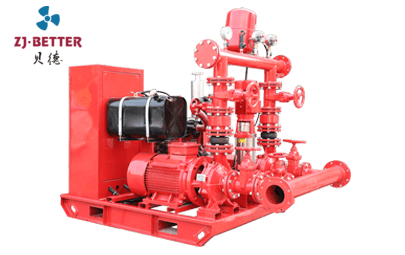

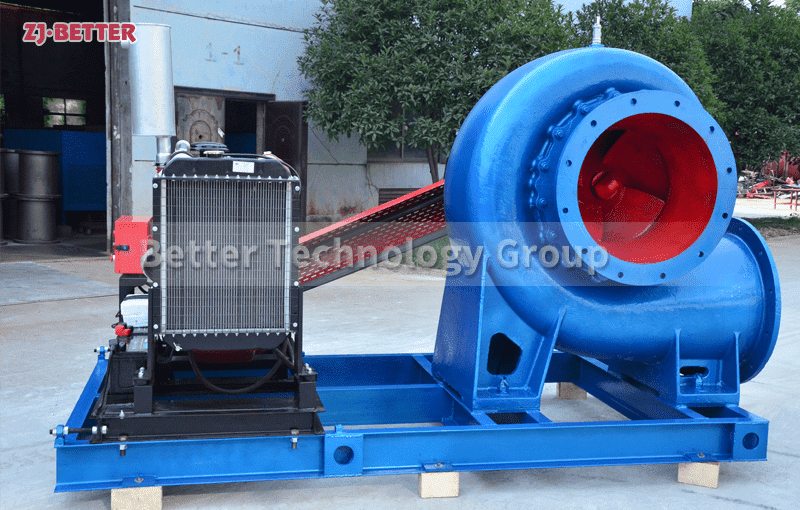

High-performance diesel fire pumps, featuring high-temperature and corrosion resistance, are suitable for industrial plants, chemical bases, power plants, and high-rise buildings. Their independent diesel powertrain ensures stable water supply even in power outages, while their intelligent control system enables automatic start-up and remote monitoring. With their robust construction, easy maintenance, and efficient and reliable operation, they provide a robust and safe emergency water supply solution for various firefighting projects.

As an indispensable core power source in firefighting systems, diesel fire pumps are crucial for ensuring fire safety thanks to their powerful performance, exceptional stability, and reliable operation under extreme conditions. High-temperature, corrosion-resistant diesel fire pumps, known for their exceptional performance in harsh environments, are widely used in firefighting systems in industrial plants, chemical bases, oil and gas storage and transportation facilities, power stations, large complexes, and ships and ports. The design of these pumps focuses not only on efficient water supply and reliable startup, but also on continuous operation in extreme temperatures, corrosive media, and power outages, ensuring a stable fire water source in any emergency. Diesel fire pumps are manufactured from high-quality materials, with the pump body, impeller, bearings, and sealing system engineered for corrosion and high-temperature resistance. The pump body is typically constructed of high-strength cast iron or stainless steel, effectively resistant to corrosive water, such as salt, acid, and alkali. The impeller is precisely dynamically balanced and coated with an anti-corrosion spray to ensure high efficiency even at high speeds without being affected by wear. Furthermore, the mechanical seal is constructed of high-temperature and corrosion-resistant materials such as silicon carbide and fluororubber, enabling continuous operation in environments exceeding 120°C without leakage, thereby extending the life of the unit. The diesel powertrain utilizes an internationally standardized design, offering fast engine start-up response, low fuel consumption, and low noise levels, along with robust self-priming and boost capabilities. A built-in fuel injection control system ensures combustion efficiency and output stability, enabling the pump unit to maintain continuous operation in extreme environments such as high temperatures, dust, and high humidity. Unlike electric pumps, diesel fire pumps do not rely on an external power source and can independently start during power outages, providing reliable water supply support at fire or disaster sites. The control system, a crucial component of the diesel fire pump system, utilizes a fully automated intelligent control cabinet with manual, automatic, and remote control modes. The system monitors key operating parameters such as oil pressure, water pressure, speed, temperature, and fuel level in real time. In the event of anomalies, such as low oil pressure or high water temperature, the system will immediately generate an alarm or automatically shut down the unit for protection. The control cabinet also connects signals with the fire monitoring center. Upon detecting a fire alarm, the pump unit automatically activates water supply with a response time of less than 15 seconds, enabling intelligent, unattended, and safe operation. In terms of performance, diesel fire pumps offer significant advantages in high head and high flow rates. Pumping capacities range from tens to thousands of cubic meters per hour, and head ranges from 80 to 250 meters, depending on the model. This meets the long-distance water supply needs of high-rise buildings, tank farms, docks, and industrial and mining systems. Their efficient hydraulic design minimizes energy loss, achieving over 80% efficiency, consistent and stable output, and resisting cavitation. The entire unit undergoes rigorous performance testing to ensure that every unit meets international fire safety standards. To accommodate complex installation environments and application scenarios, diesel fire pump units typically utilize a modular design. The base, pump body, engine, and control system are integrated into a sturdy steel platform, making them easy to transport, install, and commission. Users simply connect the unit to the pipe network and oil lines for rapid commissioning, significantly shortening the installation cycle. The equipment can also be integrated with electric pumps and pressure-stabilizing pumps to create a dual-power fire water source solution with complementary primary and backup functions, thereby enhancing the reliability and redundancy of the entire fire protection system. Seismic and corrosion resistance are another key feature of diesel fire pumps. The pump body is treated with epoxy resin spraying and anti-corrosion paint, which not only resists salt spray corrosion in marine environments but also withstands prolonged UV exposure and temperature fluctuations. All fasteners are made of stainless steel or galvanized steel to prevent rust and loosening. For high-temperature environments such as chemical plants, refineries, and power plant boiler areas, the equipment is equipped with a double-layer heat dissipation system and heat-resistant protective cover to ensure efficient cooling of the engine and pump body even during continuous high-temperature operation, preventing performance degradation caused by thermal expansion and contraction. The diesel fire pump is designed with ease of use in mind. Clearly marked oil, water, and electrical control lines facilitate quick inspection and replacement of wearing parts. The oil filter, water filter, and cooling system are all removable, simplifying and minimizing maintenance. In addition, automatic lubrication and self-diagnostic functions ensure the pump maintains optimal starting performance even during extended periods of standby operation. The system periodically automatically activates test mode to ensure the pump is ready for immediate response at critical moments, without the need for manual intervention. Energy efficiency is a key characteristic of modern firefighting equipment. This diesel fire pump utilizes a high-precision fuel injection system and air mixing control technology to achieve improved combustion efficiency and reduced emissions. Compared to traditional models, its fuel efficiency is over 10% higher, and its emissions meet international environmental standards, making it suitable for projects with stringent environmental requirements. To minimize noise, a high-density soundproof enclosure and optimized exhaust structure reduce operating noise to below 85 decibels, making it suitable for installation in indoor equipment rooms or densely populated areas. Regarding safety, the pump is equipped with multiple protection mechanisms, including overspeed protection, low oil pressure protection, cooling water overheat alarm, and automatic fire-related start-up, ensuring safe and controllable operation in various abnormal situations. The fuel tank and oil pipelines are designed to be impermeable and explosion-proof to effectively prevent secondary accidents. The electrical system complies with international IEC standards and is waterproof, dustproof, and tamper-resistant, ensuring stable operation in high-humidity and high-dust environments. Diesel fire pumps, with their wide range of applications, are widely used in various fire protection projects and emergency water supply projects. For example, in large industrial parks, they serve as the primary water supply equipment, providing a high-pressure water source for factory fire protection pipe networks. In petrochemical sites, they enable remote water supply in flammable and explosive environments, reducing the risk of personnel approaching. In high-rise buildings and residential areas, they serve as a backup power system, automatically activating water supply in the event of a utility power failure. On docks, ships, and offshore platforms, their strong self-priming capacity and salt spray resistance ensure the long-term reliable operation of marine fire protection systems. Overall, the core advantages of high-temperature and corrosion-resistant diesel fire pumps lie in their reliability, durability, efficiency, and intelligence. Reliability is reflected in the independent diesel power system and redundant design, ensuring a stable water supply even in power outages, extreme climates, or disasters. Durability is reflected in the high-strength, corrosion-resistant structure and high-temperature-resistant materials, ensuring long-term operation without damage. Efficiency comes from the optimized hydraulic design and high-energy combustion system, ensuring maximum energy conversion efficiency. Intelligence, combined with automatic control and remote monitoring systems, enables 24/7 unmanned operation. This diesel fire pump is undoubtedly an ideal choice for modern firefighting systems that demand high safety standards and continuous water supply. It not only enhances overall firefighting support but also embodies the advanced integration of technology and reliability in modern firefighting equipment. It provides stronger and more stable emergency power support for various firefighting projects, becoming a vital guarantee for the safe operation of various industries.